A Multi-stage Elastic Penetration Vibration Isolation Device Based on Rubber Vibration Absorption

A rubber vibration damping and vibration isolation technology, applied in the direction of pipeline supports, mechanical equipment, pipes, etc., can solve the problems of difficult to achieve effective sealing between pipelines and bulkheads, general vibration isolation effect, poor sealing performance, etc., and achieve design Reasonable, good feasibility, and the effect of reducing radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

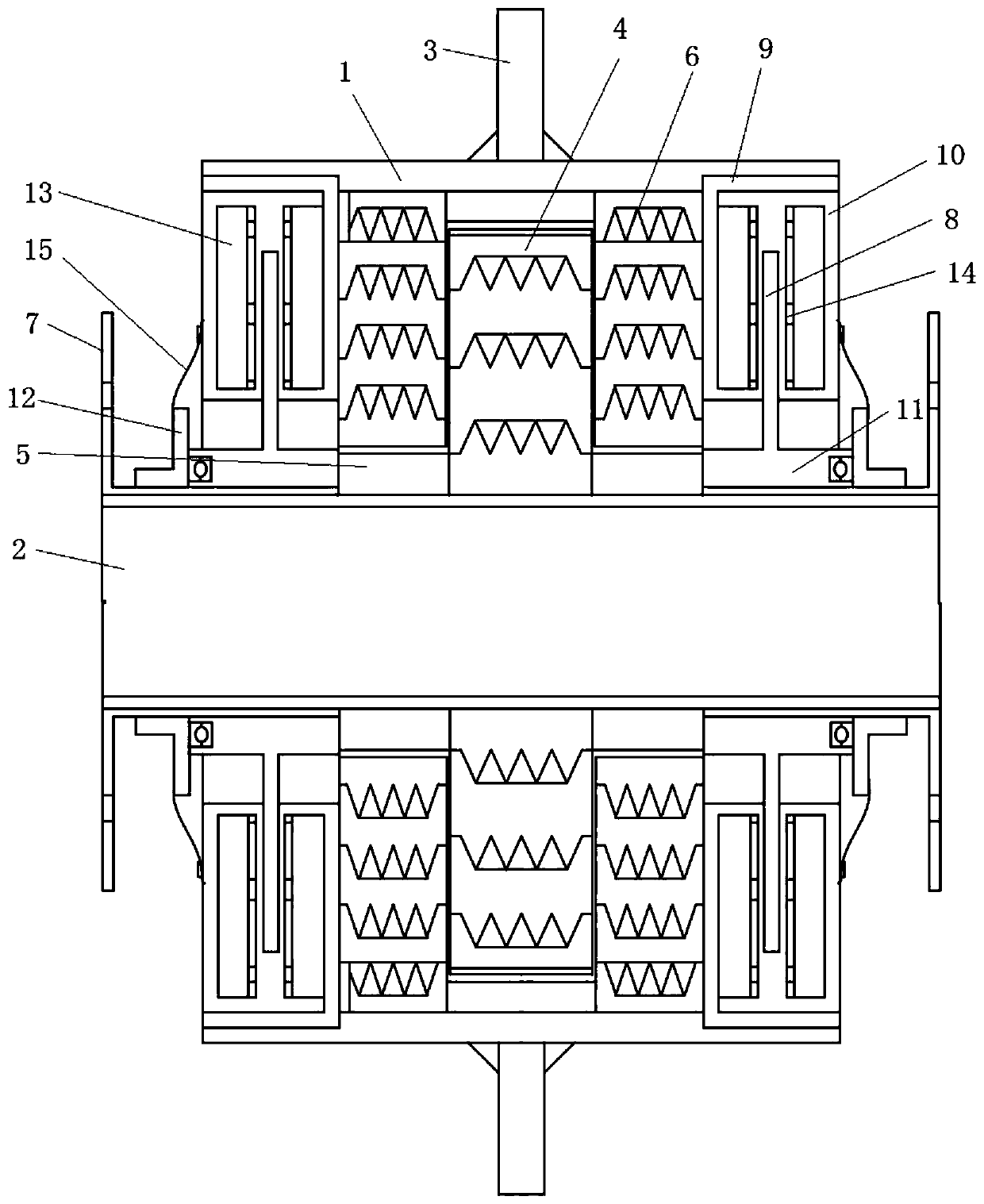

[0022] Such as figure 1 A multi-stage elastic cabin penetration isolation device based on rubber vibration damping is shown, including a housing 1, two end connectors, a vibration isolation assembly and two seals all located inside the housing 1, the housing The outer wall of 1 is fixedly connected with the cabin bulkhead 3 (can be welded), and the sealing assembly is arranged symmetrically with the vibration isolation assembly as the center. ; The two end connectors are located at both ends of the shell 1 and connected with the sealing assembly.

[0023] Preferably, the vibration isolation assembly includes a primary vibration isolation group and several secondary vibration isolation groups, the secondary vibration isolation groups are axially symmetrically distributed around the primary vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com