Lightning protection construction method for cantilever scaffold of high-rise building

A technology of cantilevered scaffolding and lightning protection and grounding, which is applied to scaffolding supported by housing structures, buildings, building structures, etc. , to ensure the lightning protection effect, the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

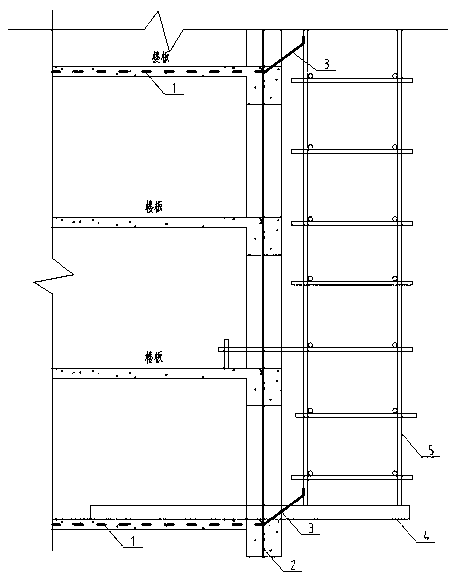

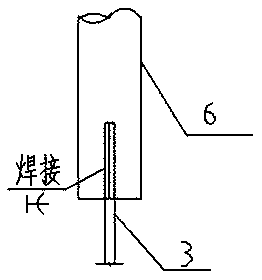

[0018] like figure 1 The schematic diagram of the lightning protection grounding connection of the cantilevered scaffolding of a high-rise building is shown. In the construction stage of the main structure of the high-rise building, the main structure of the high-rise building is designed to be equipotentially connected by the frame beam steel bars around the building to form an internal pressure equalizing ring on every third floor. , the frame beam steel bar is effectively welded to the down conductor 2 of the steel bar in the column, and the down conductor 2 of the steel bar in the column is connected with the steel bar of the pouring pile. When a lightning strike occurs, the current is transmitted from top to bottom, and finally the down conductor 2 of the steel bar in the column It is transmitted to the cast-in-place pile foundation, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com