Large-caliber drainage pipeline construction assembly and construction method thereof

A drainage pipe and large-diameter technology, which is applied to large-diameter drainage pipe construction components and their construction fields, can solve the problems of pipeline integrity, low stability, inability to guarantee the straightness of the pipeline, and narrow working surface on the construction site, etc. Construction organization, reducing the influence of external factors, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

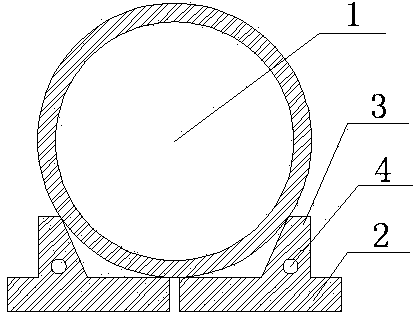

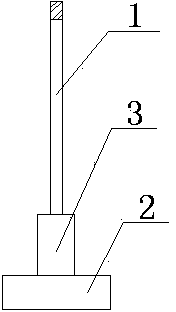

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises pipeline 1, and pipeline 1 is arranged on two pipeline pads 2, and the top of pipeline pad 2 is fixedly connected with pipeline stabilizing body 3 respectively, can make foundation one-time pouring complete, and pipeline stabilizing body 3 is connected with pipeline 1 respectively. Tangentially, hoisting holes 4 are respectively arranged on the pipe stabilizing body 3, which is convenient for construction and installation.

[0019] Adopt the construction method of large-diameter drainage pipeline of the present invention, construction step is:

[0020] (1) After the excavation of the trench, clean the bottom of the trench according to the elevation of the designed bottom of the trench. Under the premise of meeting the design bearing capacity of the foundation, hang a line between the two designed inspection wells to control the centerline position of the pipeline an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com