Concrete formwork installation compactor and its installation structure and installation method

A technology of concrete formwork and compactor, which is applied to the joints of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of affecting the appearance, increasing installation time, and increasing workload. , to achieve the effect of avoiding muddy water dripping, increasing the speed of disassembly, and increasing the speed of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

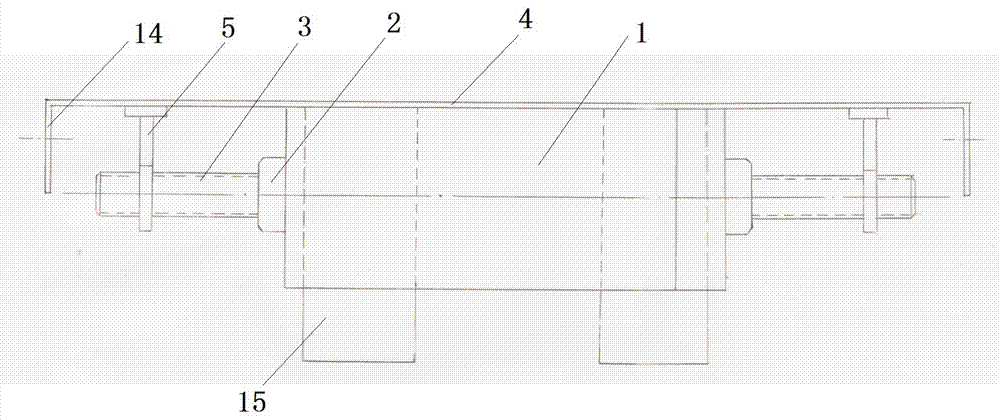

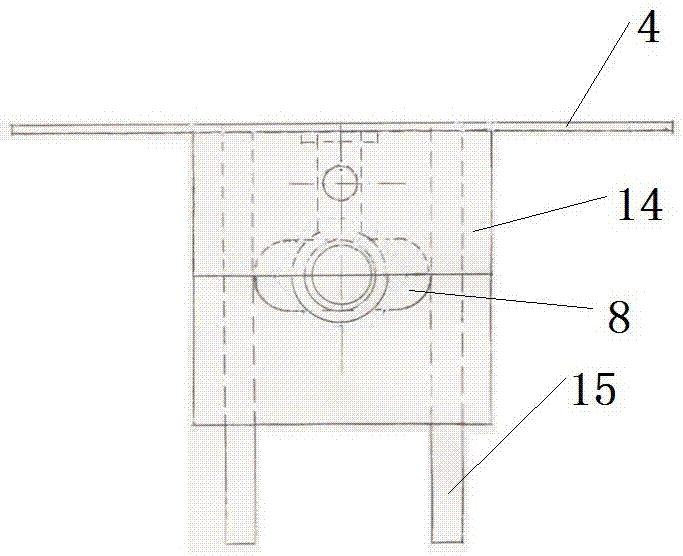

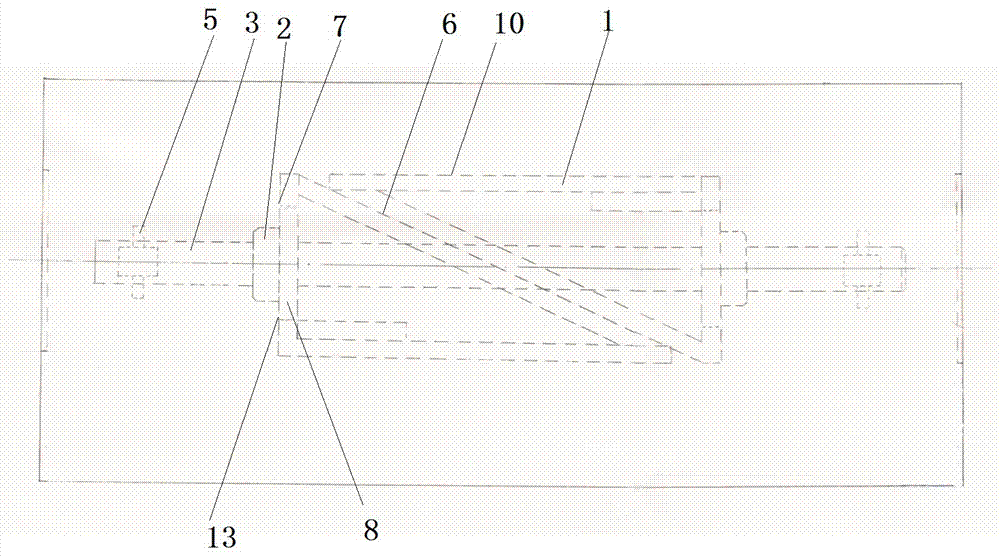

[0028] The concrete formwork installation compactor of the present invention includes two oppositely arranged and relatively movable wedges (triangular sliders) 1 , and a screw 3 with locking nuts 2 at both ends is pierced between the two wedges 1 .

[0029] Further, in order to design rationally, the upper surfaces of the above two wedges 1 are installed with leak-proof cover plates 4 straddling the two adjacent formworks. The leak-proof cover plate 4 is conducive to the leakage prevention of muddy water between the two templates, and also helps to pull it down when the template is removed, so as to realize the effect of quickly removing the template.

[0030] Further, in order to design rationally, the lower surface of the leak-proof cover is provided with two standing pieces 5 , and the two standing pieces 5 are sleeved on both ends of the screw rod 3 . This vertical piece 5 can be a piece, has perforation in the middle to be enclosed within on the screw rod 3, or vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com