Semi-automatic grinding machine

A rail grinding machine, semi-automatic technology, applied in the direction of track, track laying, track maintenance, etc., can solve problems such as unresolved grinding, achieve the effects of improving work efficiency and economic benefits, increasing track laying speed, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be further described with reference to the drawings.

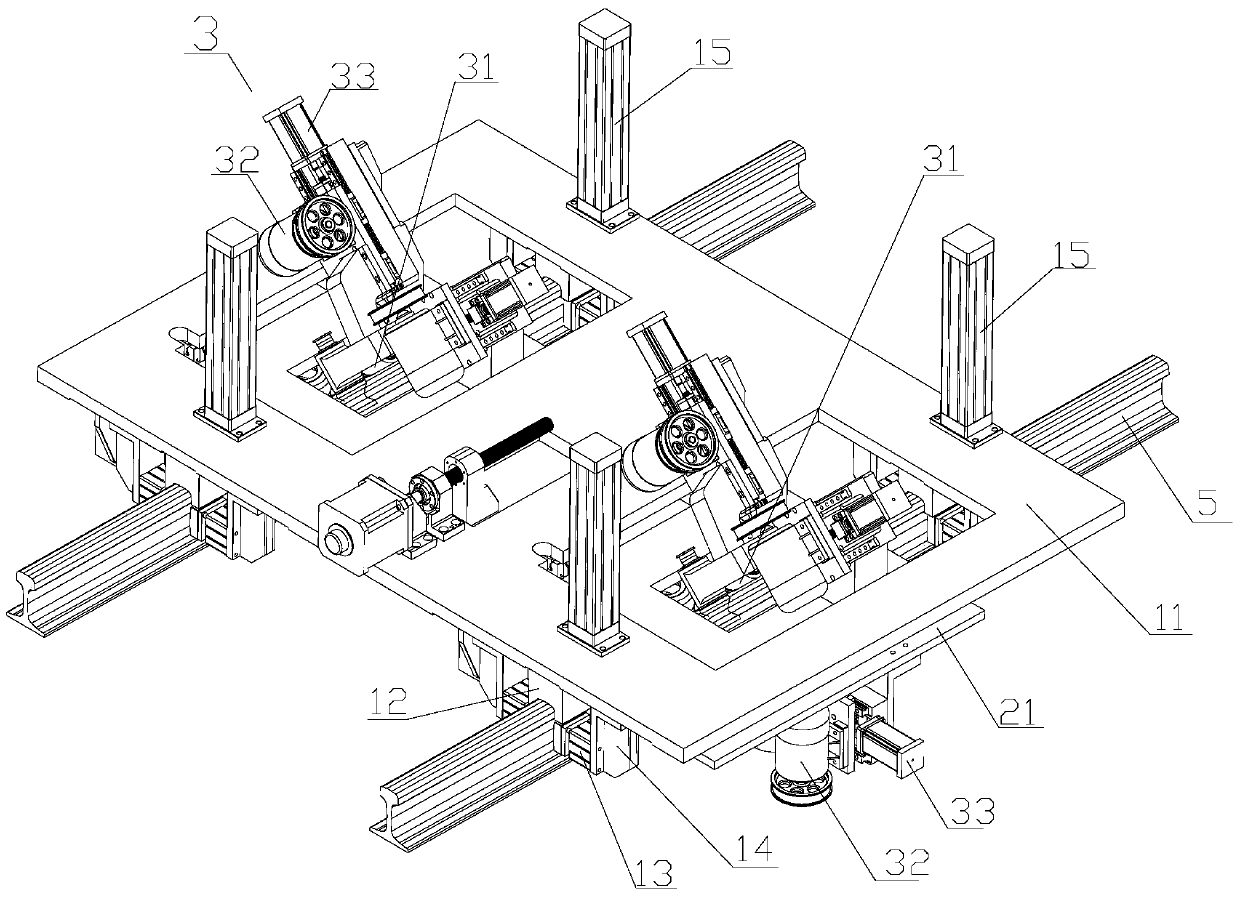

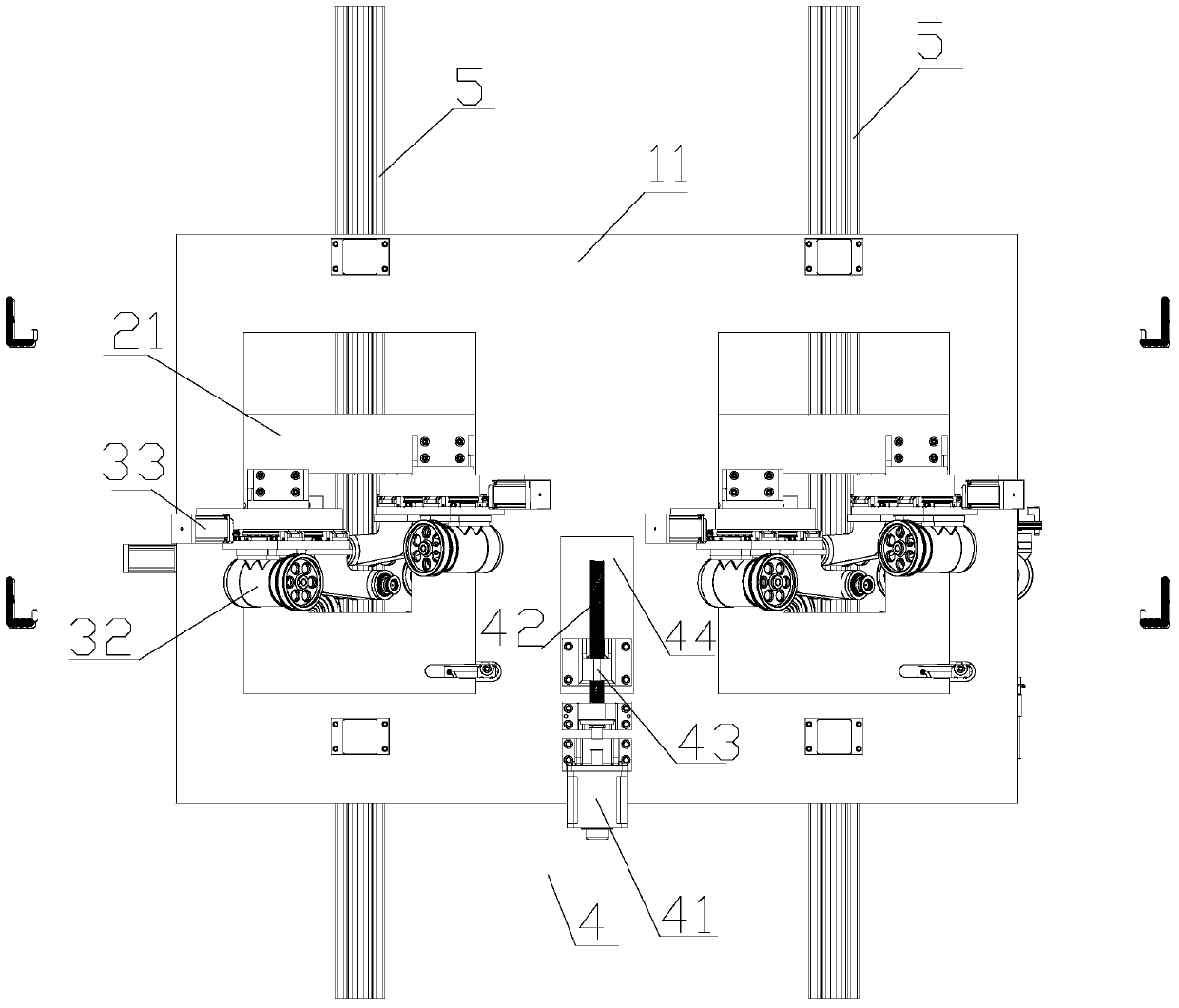

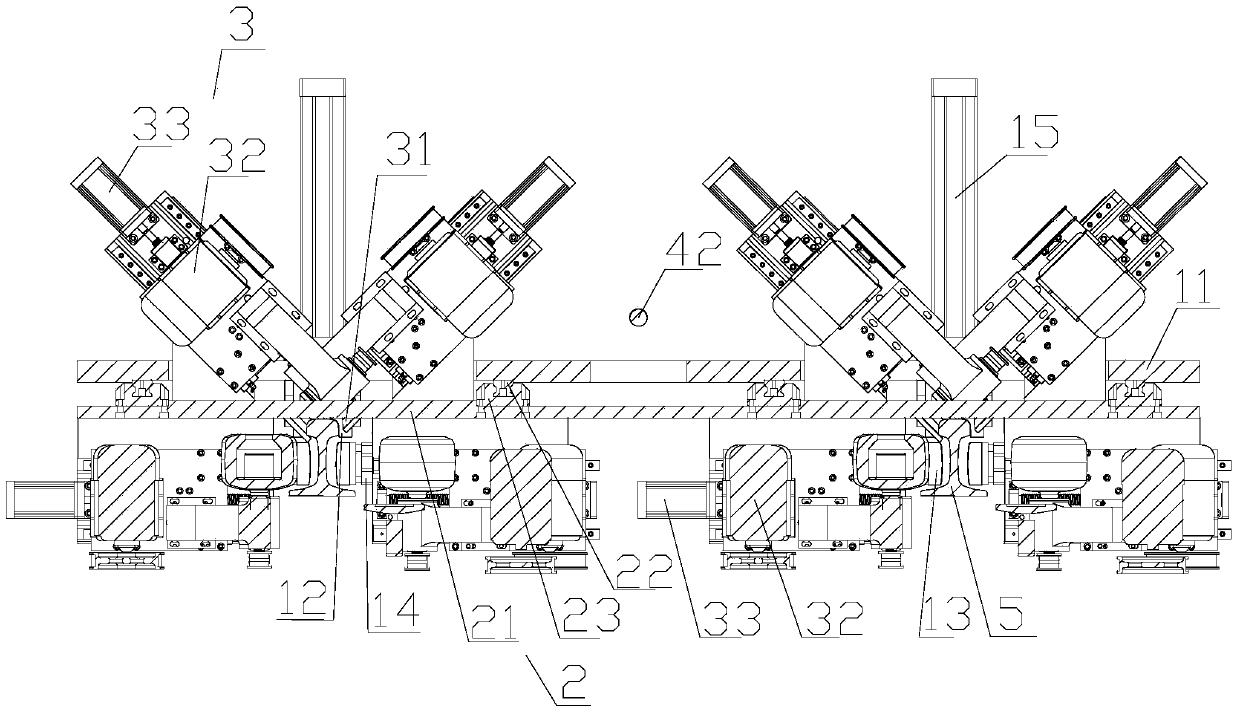

[0029] See Figure 1 to Figure 6 , Figure 1 to Figure 6 Shown is the first embodiment of the present invention, which is a "dual track" semi-automatic rail grinding machine, which can grind two side-by-side rails at the same time; it mainly includes a rail fixed platform, a translation platform and several grinding components. This embodiment is used on the construction site of a railway engineering site, and the object for grinding and shaping is a 60Kg rail.

[0030] Among them, the rail fixed platform is erected and fixed horizontally on two side-by-side rails, and the horizontally movable translation platform is connected to the rail fixed platform through a sliding mechanism; a sliding platform is provided between the rail fixed platform and the translation plate to realize the horizontal movement of the translation platform mechanism.

[0031] See Figure 4 The rail fixed platform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com