Winding drum material unwinding and winding printing tandem axle-free fixing unit

A reel and unit technology, which is applied to the field of reel material unwinding and printing without serial shaft fixed units, can solve the problems of high labor intensity, heavy weight and high physical labor intensity when disassembling the inflatable shaft, so as to improve the subjective effect and improve the The effect of improving the service life and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

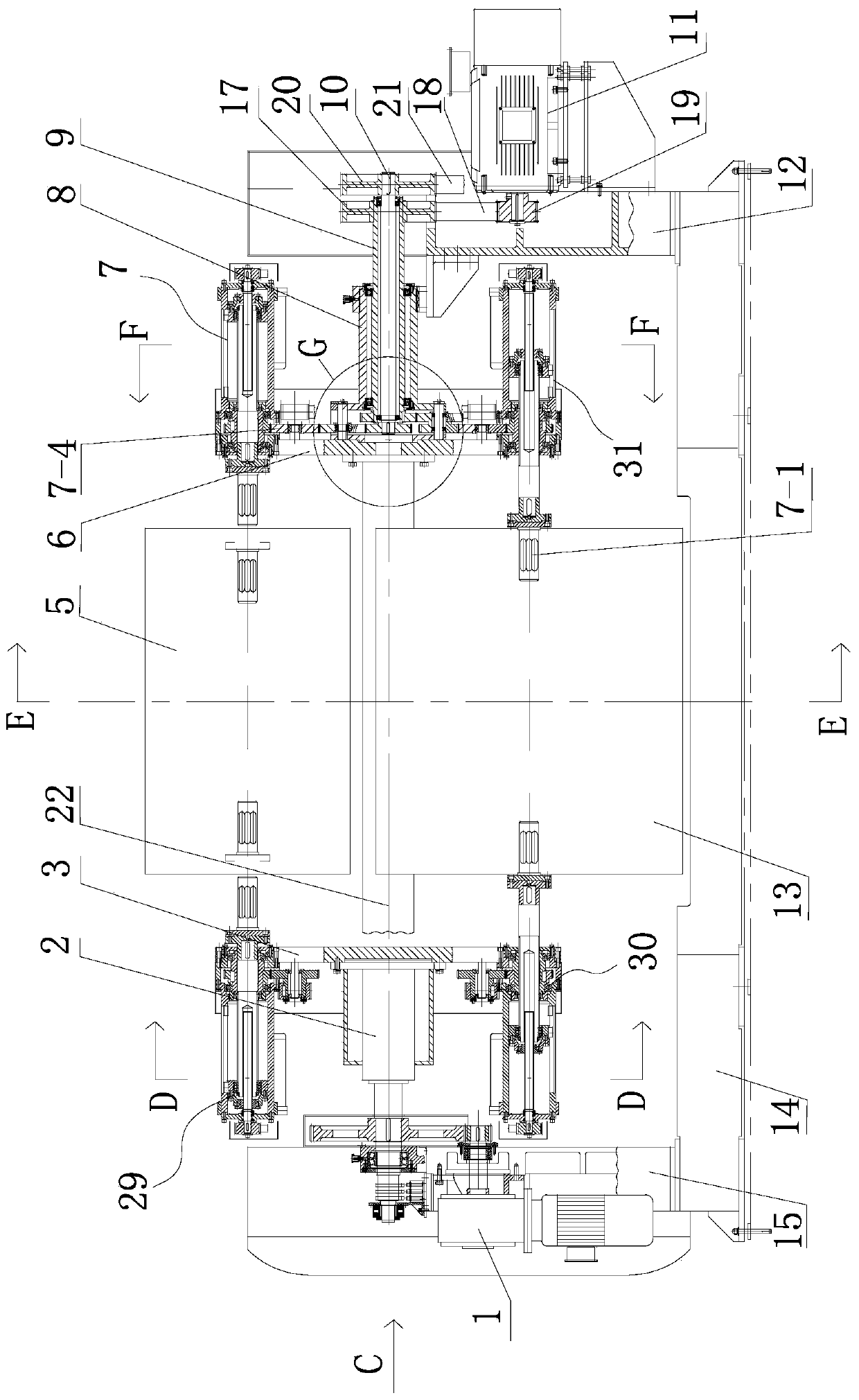

[0032] Such as figure 1 The roll material unwinding and printing without serial axis fixed unit includes a base 14, a left wall panel 15, a right wall panel 12, a transfer tray, a transposition power motor 1, a first left clamping machine head 29, a first right Clamping machine head 7, the second left clamping machine head 30, the second right clamping machine head 31, the first bridge transmission mechanism and the second bridge transmission mechanism. The base is horizontally arranged on the ground; the left wall board and the right wall board are respectively vertically fixed on the left and right sides of the base.

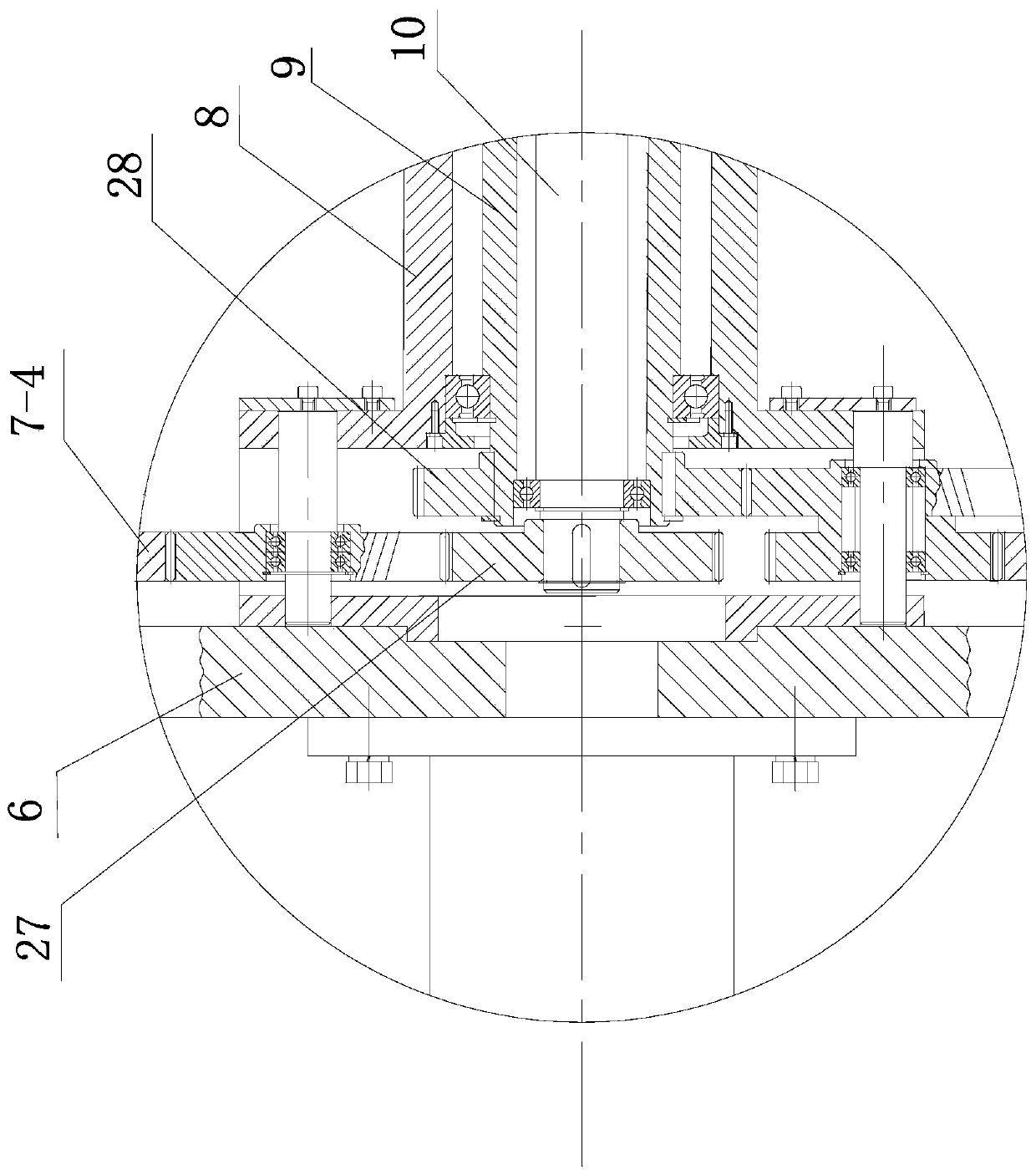

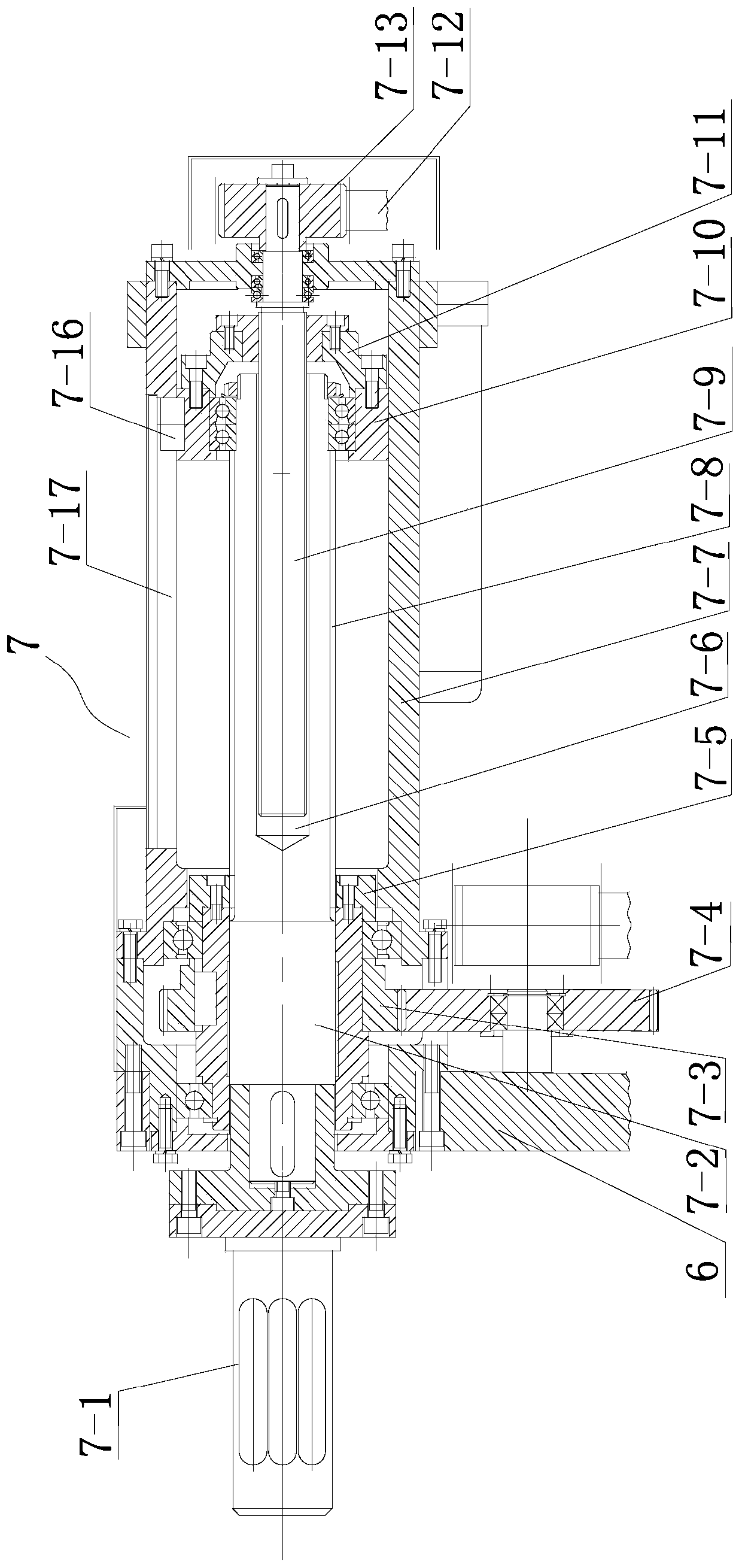

[0033]The transfer tray includes a support head 2 , a left fixed tray 3 , a power input support base 8 and a right fixed tray 6 . The support head is rotatably positioned on the left wallboard around the horizontal axis; the transposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com