Application of polyether hyperbranched polymers as demulsifier

A technology of hyperbranched polymer and hyperbranched polymer is applied in the field of petroleum additives, which can solve the problems of complex components of high-functionality hyperbranched polyester and polycarbonate, so as to broaden the scope of use, reduce the oil-water interfacial tension, improve the The effect of demulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

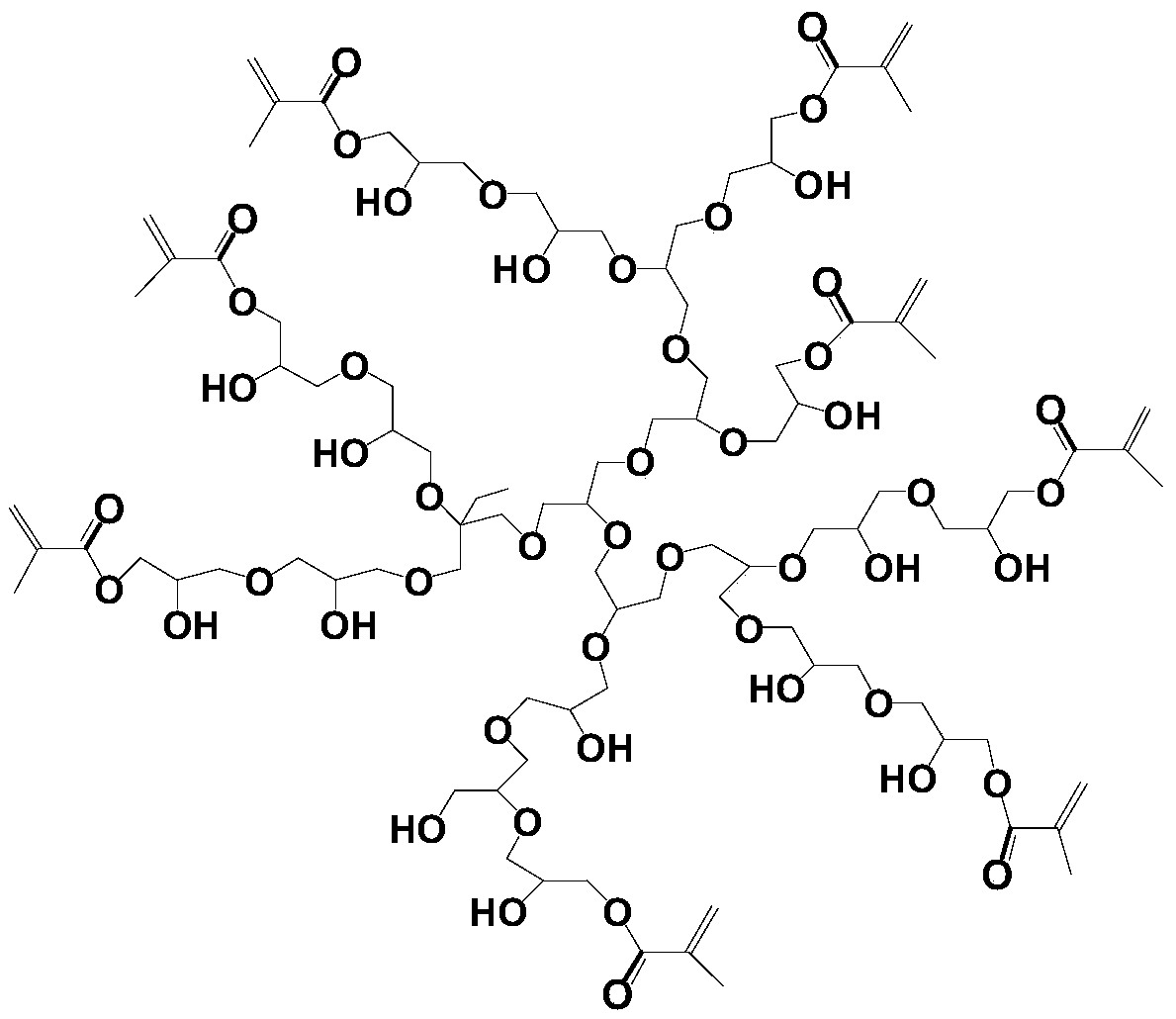

Image

Examples

preparation example Construction

[0023] Preparation of Polyether Hyperbranched Polymers

[0024] Get 5g hyperbranched polyglycidol, dissolve and disperse in an appropriate amount of DMSO (V DMSO :m HPG =9), add 1g of catalyst 4-dimethylaminopyridine, under the protection of nitrogen, add 50mL of glycidyl methacrylate (GMA) dropwise, stir vigorously at room temperature for 5h, then pour the product into 100mL of ether After stirring for 20 minutes, it can be observed that the light yellow liquid sinks to the lower layer. After repeating twice, the upper layer of ether is discarded to obtain a viscous liquid. The light yellow liquid obtained after removing the ether by rotary evaporation is HPG-MA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com