Device used for lowering acid value of TDI product produced through heavy solvent method

A technology of acid value reduction and heavy solvent, which is applied in the field of acid value reduction device of TDI products by heavy solvent method, which can solve the problem of reducing the content of acidic components in isocyanate, affecting the stable operation of the reaction yield system, high requirements for equipment size and energy consumption, etc. problems, to achieve the effects of improved stability, reasonable structure, and scientific device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

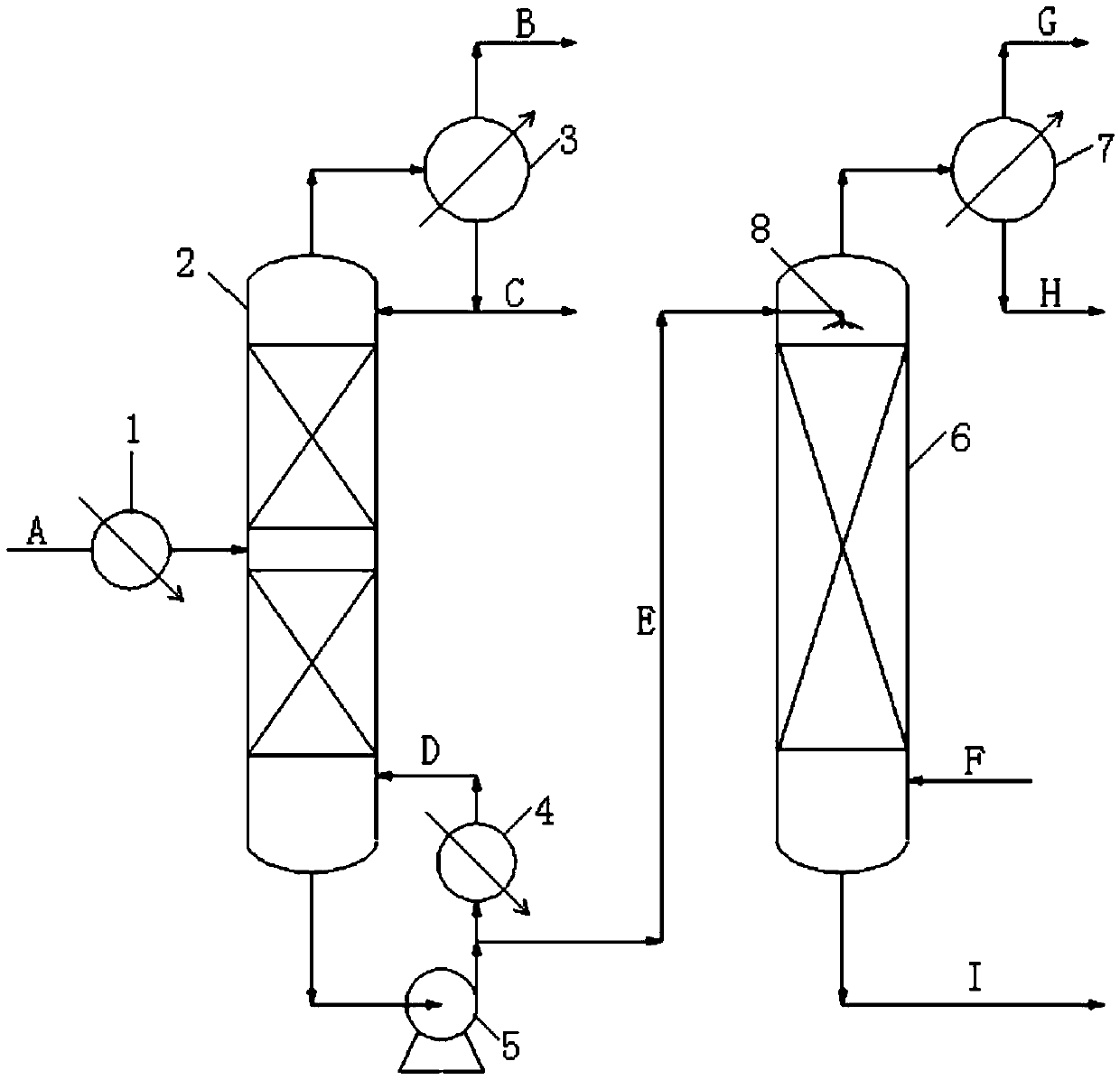

[0017] The main structure of the heavy solvent method TDI product acid value reduction device involved in this embodiment includes a feed preheater 1, a product tower 2, a product tower condenser 3, a reboiler 4, a kettle liquid pump 5, a purge tower 6, a blower Sweeping tower condenser 7 and distributing device 8, feed preheater 1 is connected to the middle part of product tower 2 in pipeline connection to realize preheating of photochemical reaction materials, product tower condenser 3 is connected to the top of product tower 2 for condensation The TDI product is recovered, the reboiler 4 connected to the bottom of the product tower 2 is used for vaporization and reflux, and the bottom of the product tower 2 is connected to the purge tower 6 in a pipeline through the kettle liquid pump 5 so as to purify the acidic components, and the reboiler 4 , kettle liquid pump 5 and purge tower 6 are connected in pipeline; the top of purge tower 6 is connected with purge tower condenser ...

Embodiment 2

[0020] The present embodiment is implemented in the acid value reduction device of embodiment 1, and the method for reducing the acid value of the heavy solvent method TDI product involved specifically includes the following steps:

[0021](1) Preheat the photochemical reaction material of toluene diisocyanate (TDI) by the heavy solvent method to 160-190 DEG C through the feed preheater 1 and then send it into the product tower 2, the control pressure is 0.5-20kpaA, and the temperature is 170-240°C; the gas phase in the product tower 2 enters the product tower condenser 3 through the top of the product tower 2, and is condensed at a controlled temperature of 40-100°C, and the non-condensable gas material is extracted from the gas phase at the top of the product tower condenser 3 to the outside The vacuum system of setting, a part of material that condenses is returned in the product tower 2 as reflux through reboiler 4, and the reflux ratio is 1.5~15, and another part of materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com