PRB filler for repairing PB/CD pollution, its preparation method and effect verification method

A technology of straw and fly ash, applied in the field of repairing Pb/Cd polluted PRB filler and its preparation, to achieve the effects of easy acquisition, cost saving and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

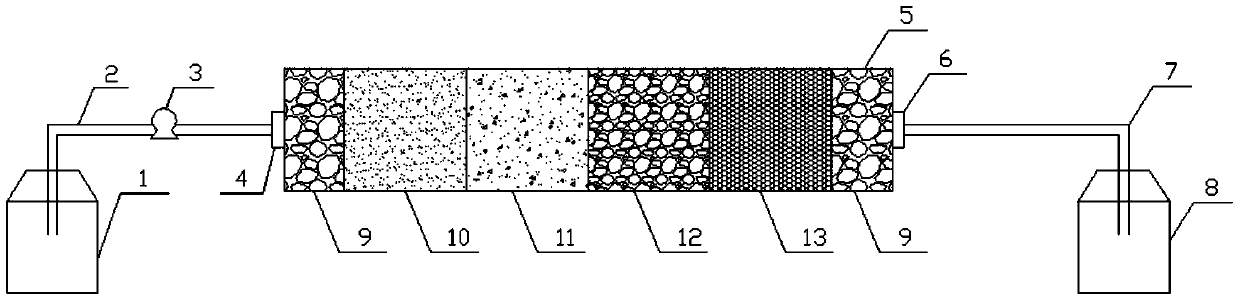

Method used

Image

Examples

Embodiment 1

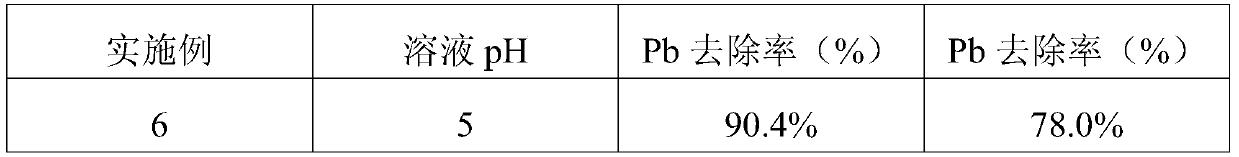

[0054] Step 1: preparing a solution for simulating Pb / Cd pollution, wherein the concentration of Pb is 5 mg / L, the concentration of Cd is 0.5 mg / L, and the pH of the solution is 6;

[0055] Step 2: According to the flow direction of the solution, in volume fraction, 10% quartz sand, 20% dry straw, 20% fly ash-based zeolite, 20% iron-manganese nodules, 20% fly ash and 10% nylon for quartz sand After the mesh bag is packed, fill it into the PRB reaction device, moisten the filler with pure water and remove air bubbles;

[0056] Step 3: Adjust the experimental temperature to 25°C, use a peristaltic pump to inject the prepared solution into the PRB reaction device at a flow rate of 6 mL / min, take a sample at the water outlet of the PRB reaction device after 12 hours, and test the sample to obtain the experimental results.

[0057] After the reaction, it was measured that the removal rate of Pb in the repaired solution was 96.0%, and the removal rate of Cd was 86.0%.

Embodiment 2

[0059] Step 1: preparing a solution for simulating Pb / Cd pollution, wherein the concentration of Pb is 5 mg / L, the concentration of Cd is 0.5 mg / L, and the pH of the solution is 6;

[0060] Step 2: According to the flow direction of the solution, by volume fraction, 10% quartz sand, 20% composite straw (dry straw and humified straw each account for 10%), 20% fly ash-based zeolite, and 20% iron-manganese nodules , 20% fly ash and 10% quartz sand are packed in nylon mesh bags and filled into the PRB reaction device, wet the filler with pure water and remove air bubbles;

[0061] Step 3: Adjust the experimental temperature to 25°C, use a peristaltic pump to inject the prepared solution into the PRB reaction device at a flow rate of 6 mL / min, take a sample at the water outlet of the PRB reaction device after 12 hours, and test the sample to obtain the experimental results.

[0062] After the reaction, it was measured that the removal rate of Pb in the repaired solution was 98.0%, ...

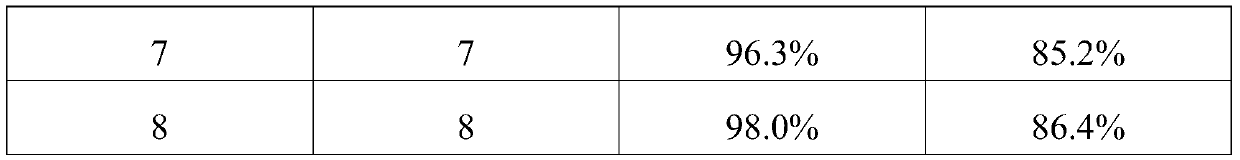

Embodiment 3~5

[0064] Compared with Example 1, only the test temperature was changed, as shown in Table 1.

[0065] Table 1 Embodiment 3~5 conditions and results

[0066] Example

[0067] It can be seen that at 25°C, the removal rate of Pb / Cd is the highest, Pb is 96.0%, and Cd is 86.0%. With the increase or decrease of temperature, the removal rate of Pb / Cd showed a downward trend. Therefore, at 25°C, the removal rate of Pb / Cd is the highest and the removal effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com