Horizontal grab bucket device with grab track being straight line

A grab and straight line technology, applied in the field of horizontal grab devices, can solve the problems of not having a unified, the running trajectory can not meet the requirements of an ideal straight line, etc., and achieve the effect of simple control and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the "left" and "right" mentioned in the present invention are only the orientations in the drawings, and should not be construed as limiting the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute conflicts with each other.

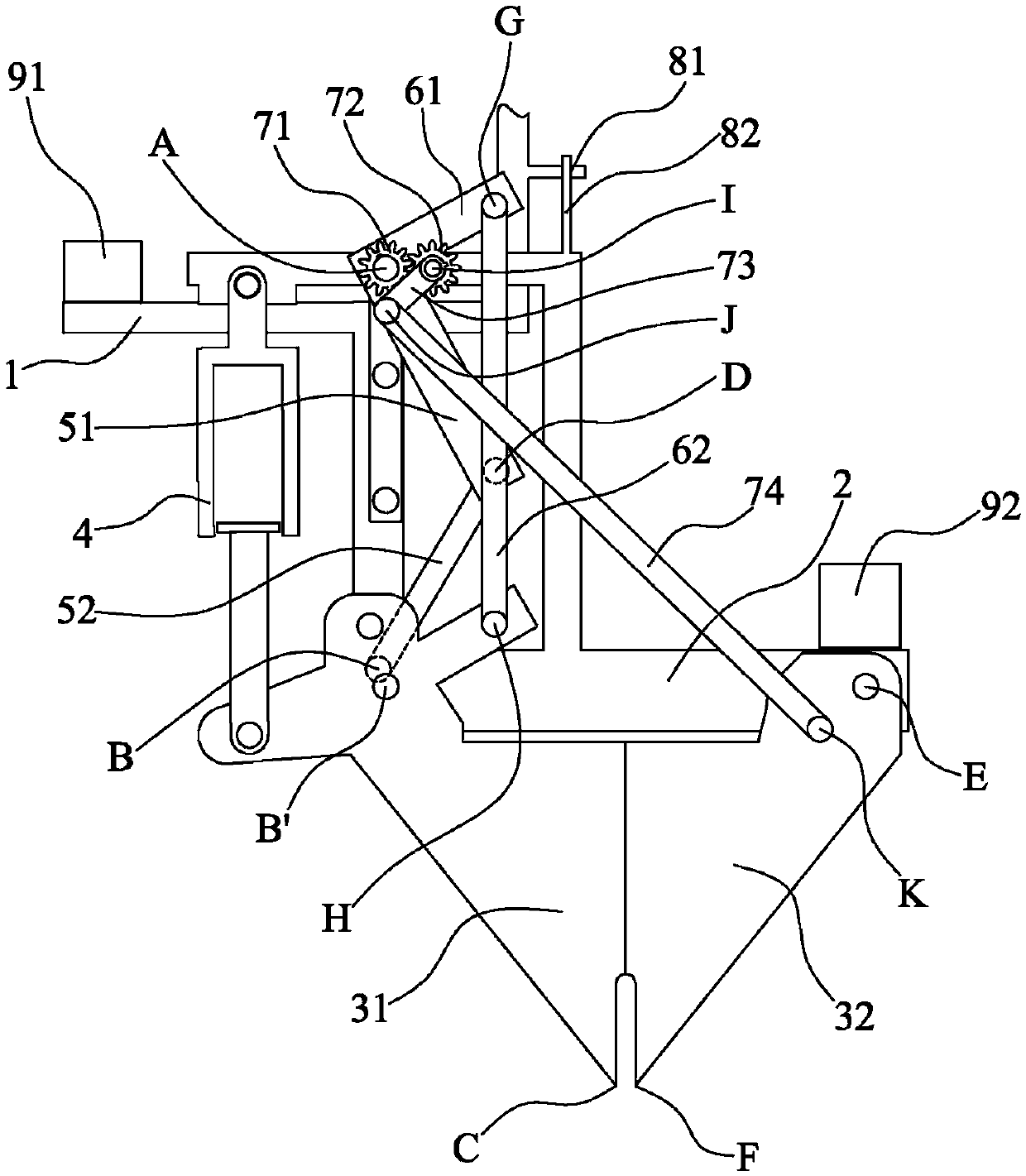

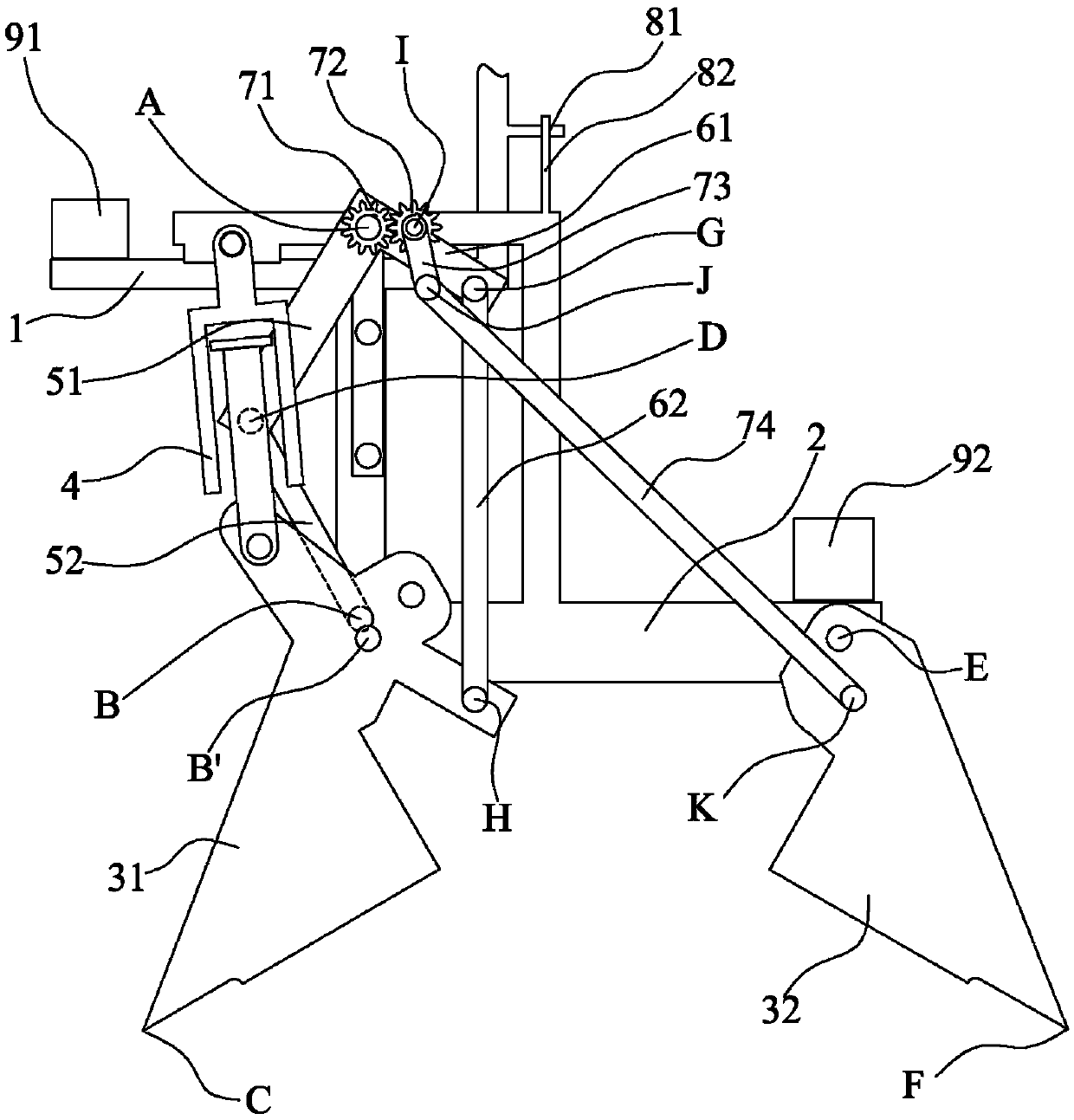

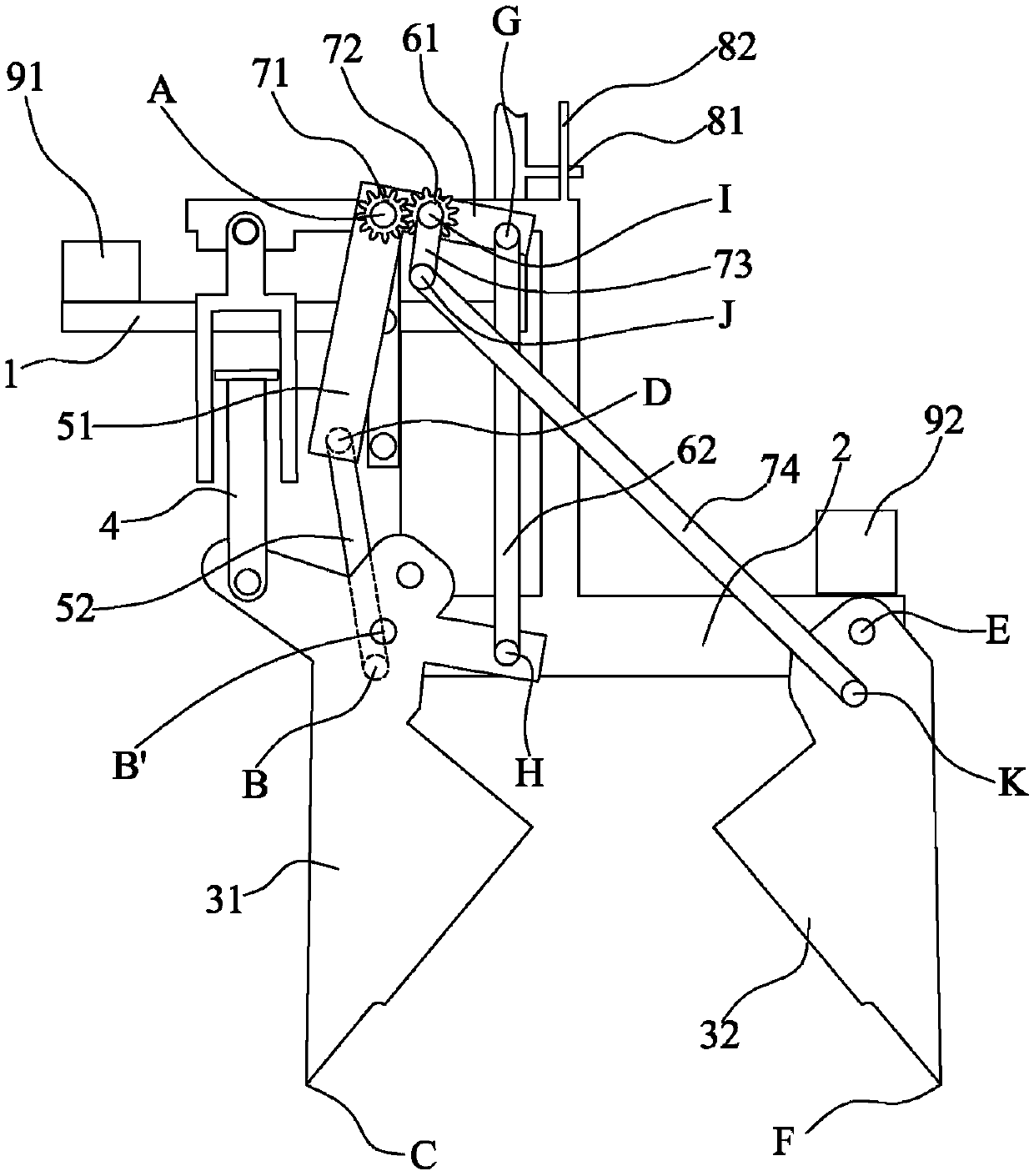

[0041] What the present invention discloses is a kind of horizontal grabbing bucket device whose grabbing track is a straight line, such as Figure 1 to Figure 3 Shown is the first preferred embodiment of the present invention. The grab device includes a fixed seat 1, a movable seat 2, a left grab body 31, a right grab body 32, a power mechanism, a first connecting rod 51, a second connecting rod 52, a drive mechanism and a synchronous mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com