Active Component Coating Cooling System for Motor Vehicle Exhaust Gas Purification Catalyst Carrier

A technology for active components and exhaust gas purification, which is used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve high cooling efficiency, lower production costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

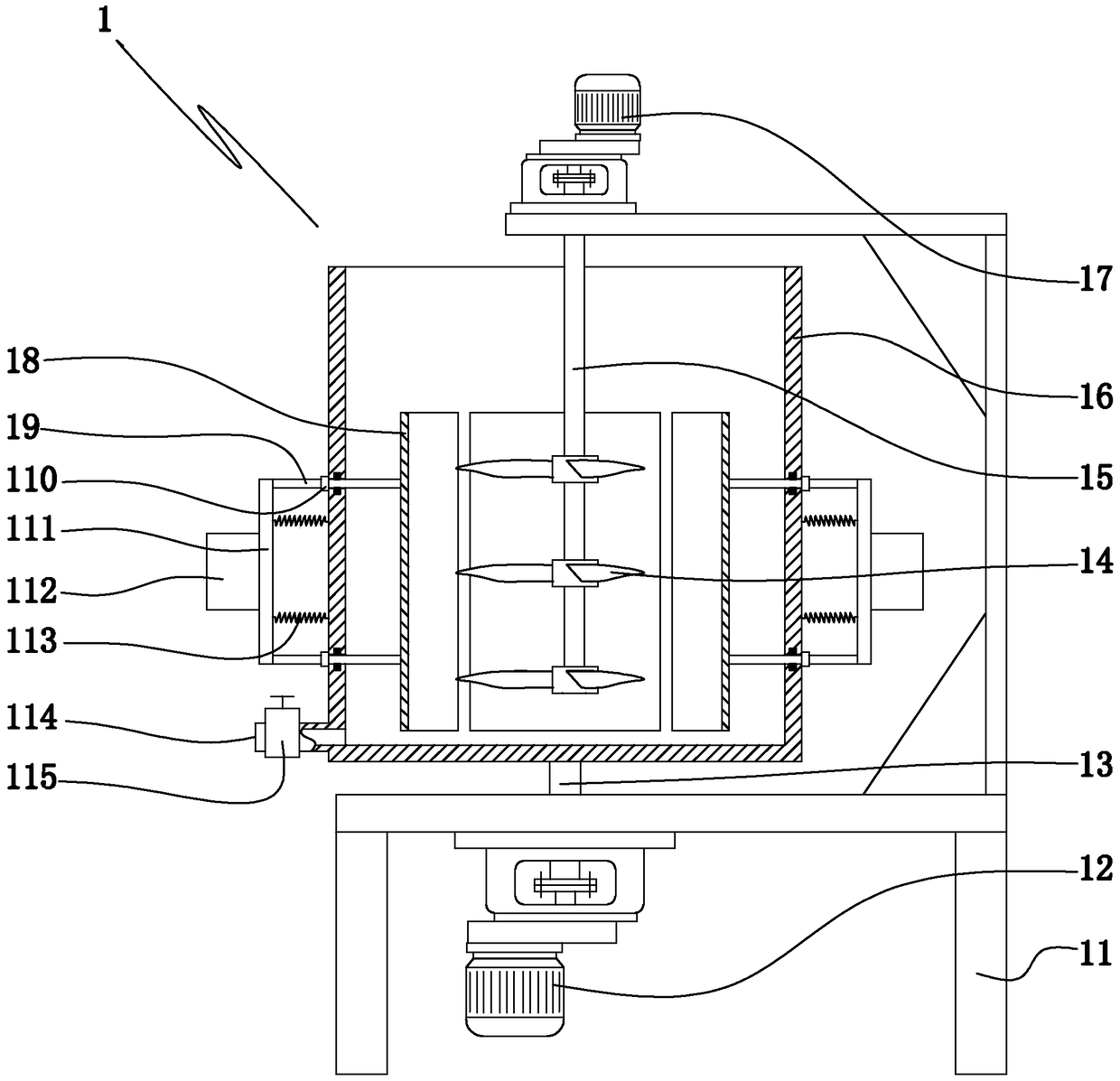

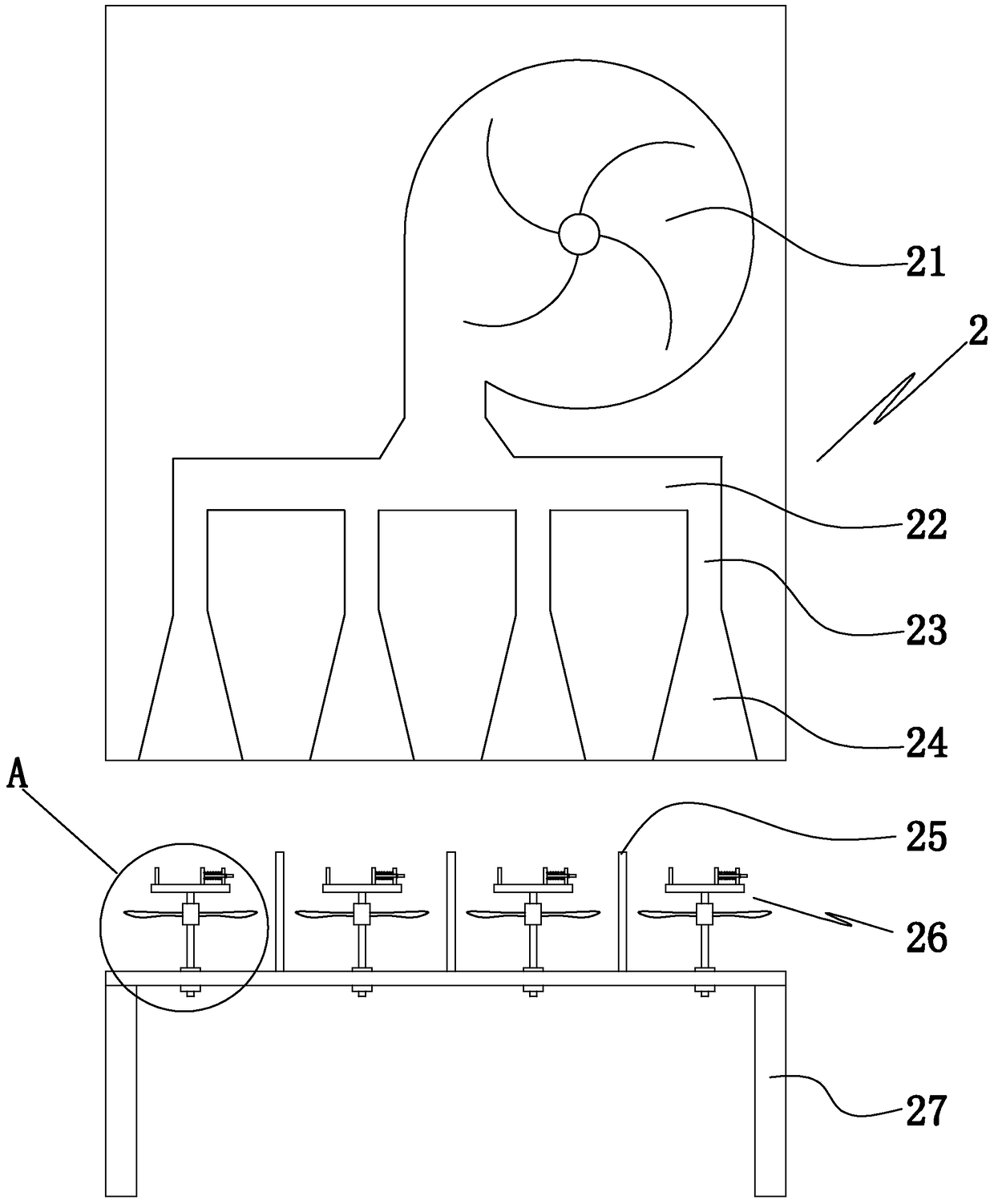

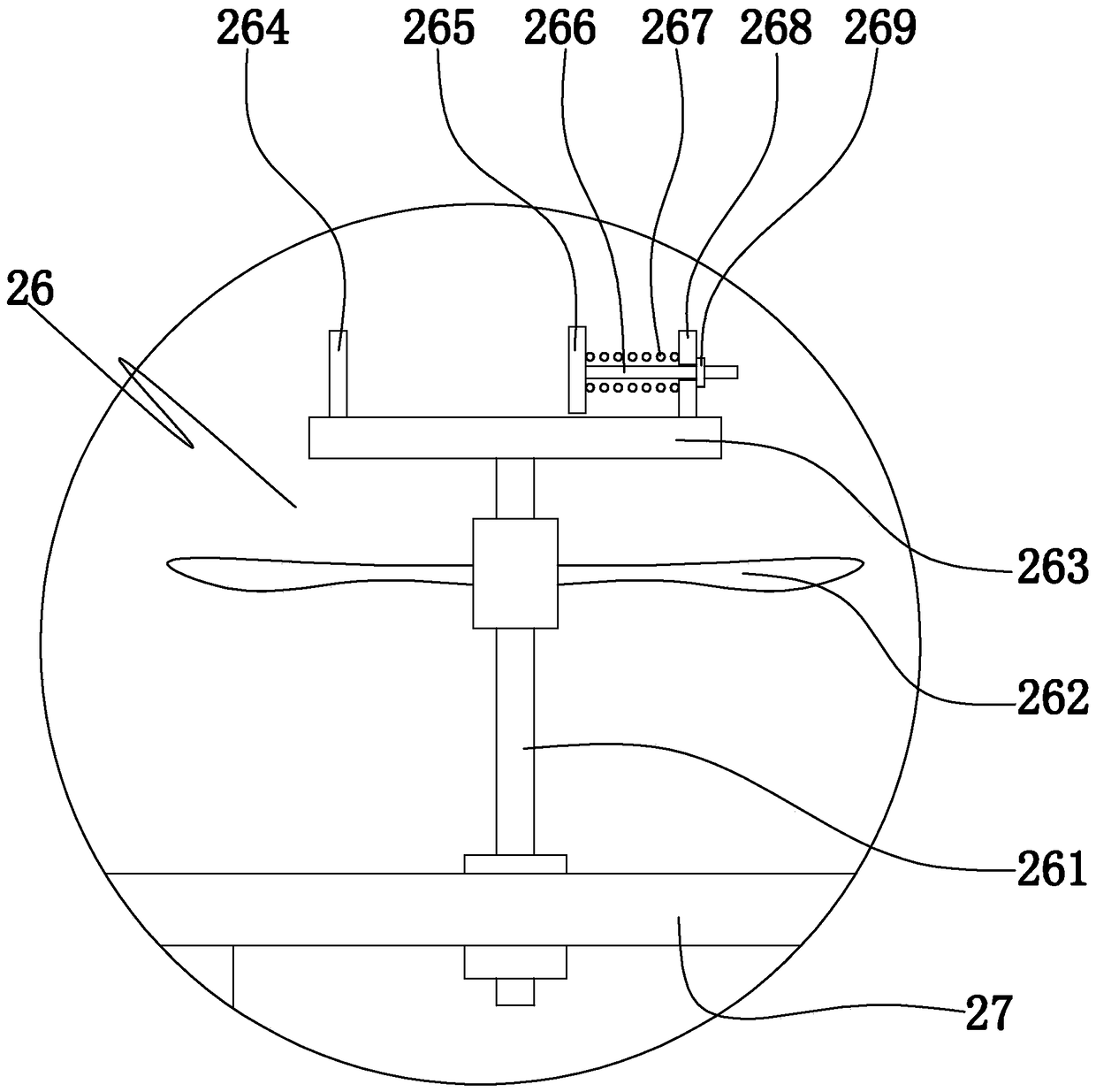

[0027] An active component coating cooling system for a motor vehicle tail gas purifying catalyst carrier includes an active component distributing device, a drying device and a cooling device.

[0028] like figure 1 As shown, the active ingredient dispensing device includes a first support frame 11, a batching barrel 16 with an open upper end arranged on the first support frame and a slurry stirring device arranged on the first support frame. The batching barrel is a cylinder. A discharge pipe 114 is provided at the bottom of the batching barrel, and a switching valve 115 is provided on the discharge pipe. The batching barrel is rotatably arranged on the first support frame through a vertical shaft 13 . The batching barrel is arranged coaxially with the vertical shaft. The first supporting frame is provided with a second rotary driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com