Mute terminal crimping machine

A terminal machine, silent technology, applied in electrical components, circuits, connections, etc., can solve problems such as unfavorable enterprise development needs, working environment impact, low efficiency, etc., to achieve the effect of easy movement, high degree of automation, and less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

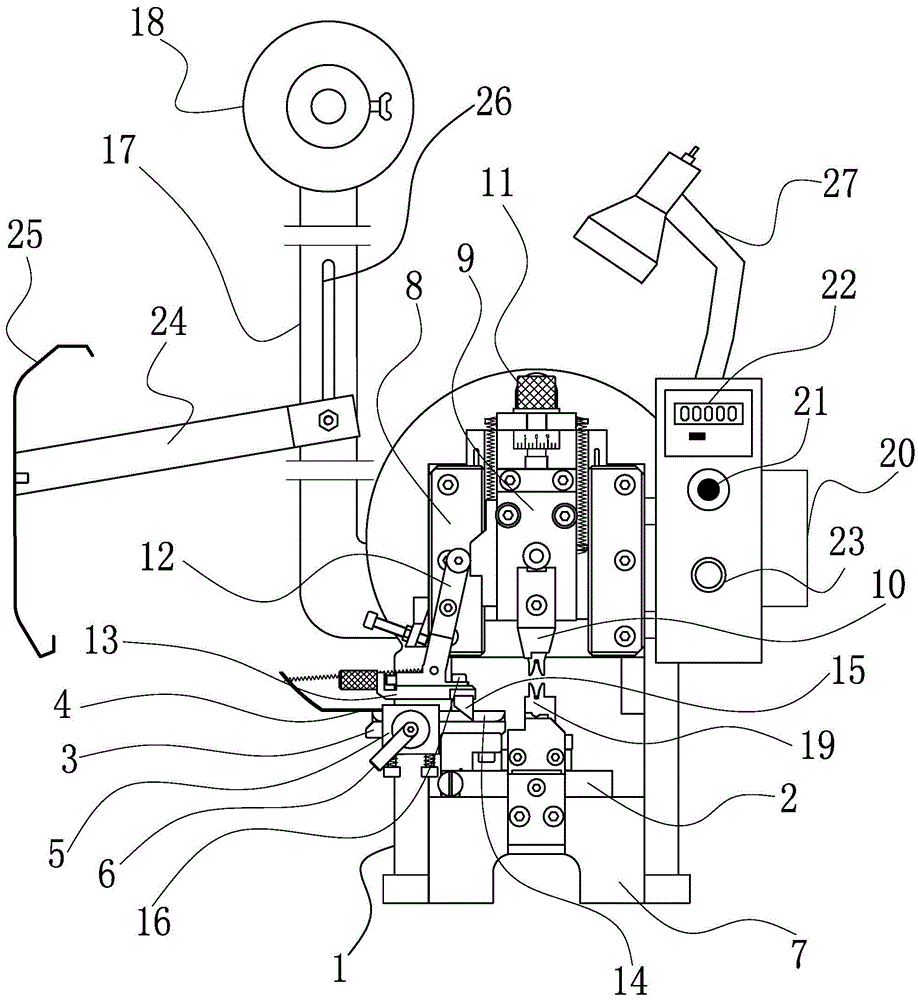

[0019] Embodiment: A silent terminal machine, including a frame 1, a base 7, and a wire conveying mechanism and a cutter bottom plate 2 arranged on the base 7; a wire adjustment device is correspondingly provided on the wire conveying device; A wire cutting device is provided, and the wire cutting device is connected to the frame 1; the wire conveying device includes a pressing end plate 5, a sliding material sheet 14, a fixed seat 3 of the feeding plate, and a feeding material set on the fixing seat 3 of the feeding plate. The cover plate 4; the pressure end plate 5 is provided with an adjustment handle 6, and the adjustment handle 6 is used to adjust the moving position of the material plate fixing seat 3 and the sliding material sheet 14; the wire cutting device includes an upper knife fixedly connected with the frame 1 Seat 8, the cutter block 9 that slides up and down in the middle of the upper knife fixing seat 8; the lower end of the cutter block 9 is provided with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com