Three-in-one lithium battery cap assembly device

A technology for assembling equipment and lithium batteries, which is applied to secondary batteries, battery assembly machines, and secondary battery manufacturing. Good synergy and continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

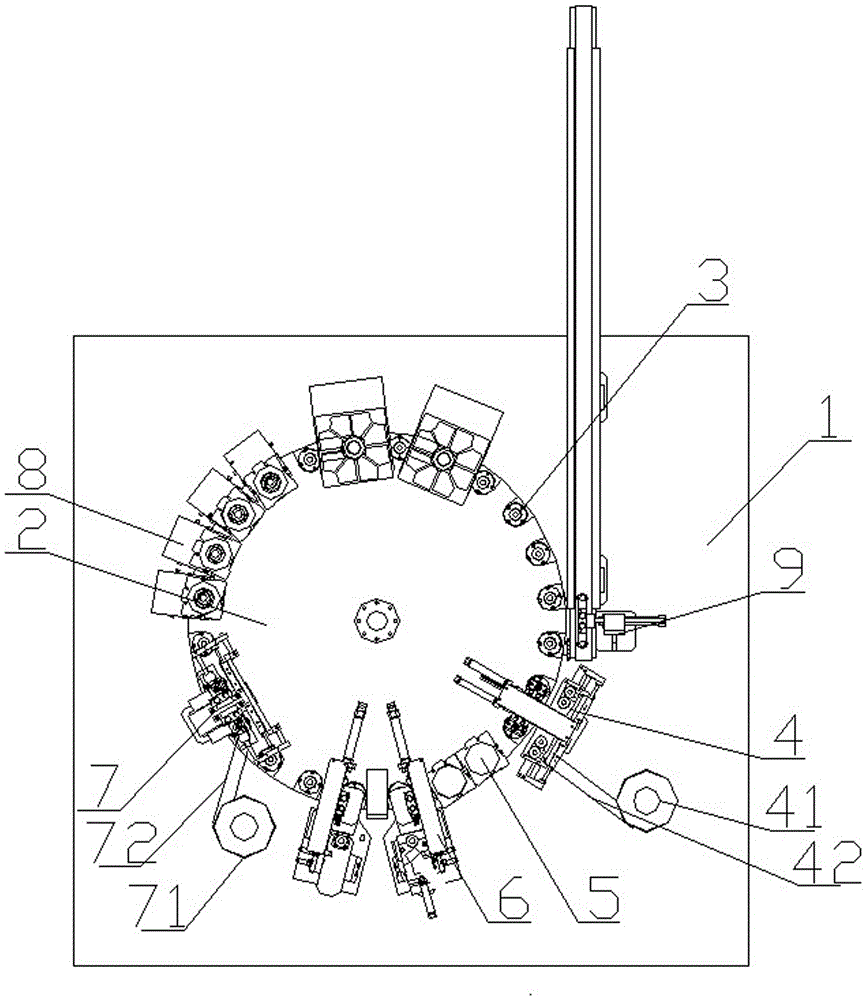

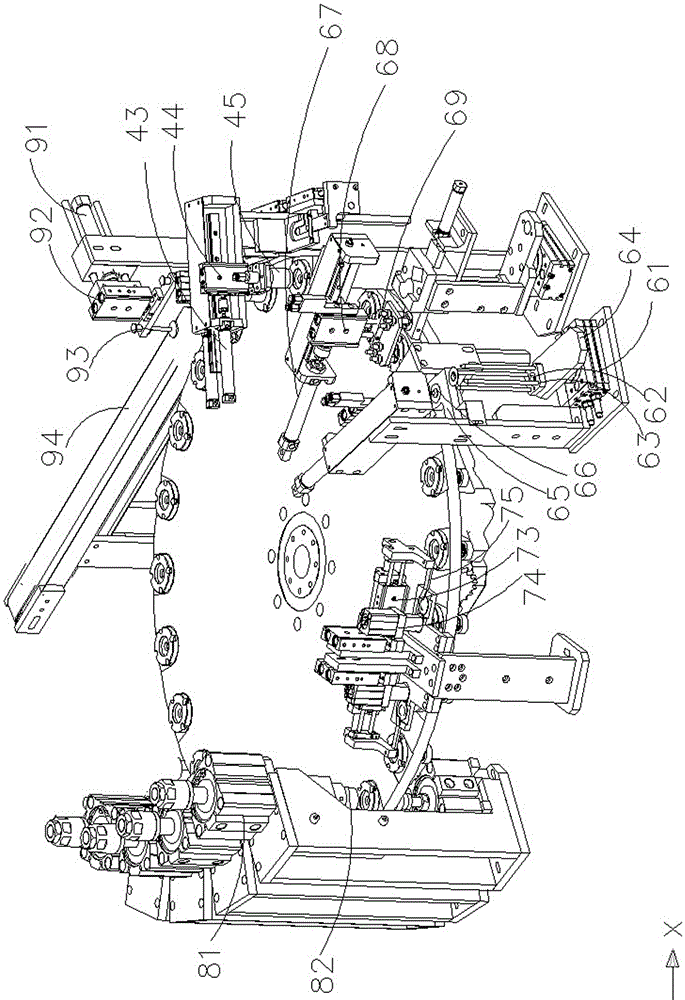

[0019] A three-in-one lithium battery cap assembly equipment, including a base 1, a turntable 2 is installed on the base 1, and the turntable 2 is driven by a stepping motor; the turntable 2 is provided with a circle of uniformly sunken circular stations 3. There are evenly distributed uprights directly under the turntable, and the uprights are fixedly installed on the base and correspond to the circular stations; along the outer circumference of the turntable, there are explosion-proof disk feeding station 4, hole reaming station 5, Gasket loading station 6, upper cover loading station 7, pressing and sealing station 8 and discharging station 9;

[0020] The explosion-proof disk feeding station 4 includes a first vibration plate 41, a rupture-proof disk flow channel 42 and a rupture-proof disk feeding device, and the explosion-proof disk fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com