High-temperature superconducting twisted wire winding method

A high-temperature superconducting and superconducting wire technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the process and method that has no published patents and documents, and has no second-generation high-temperature superconducting tape cutting and weaving performance and other issues to achieve the effect of improving performance, increasing critical current, and reducing AC loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

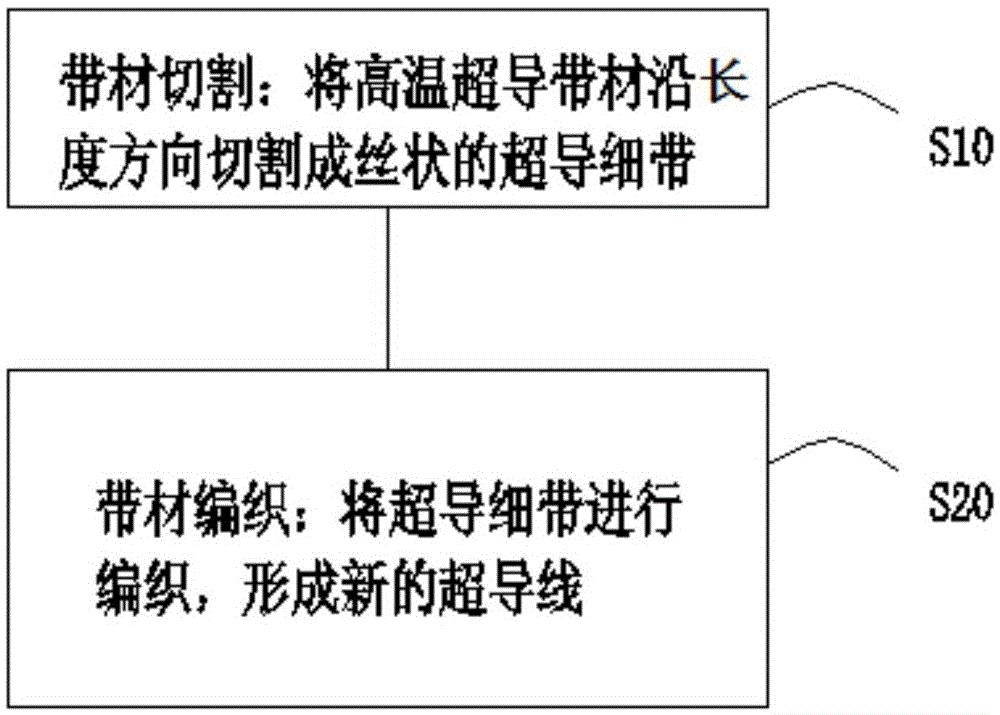

Method used

Image

Examples

Embodiment 1

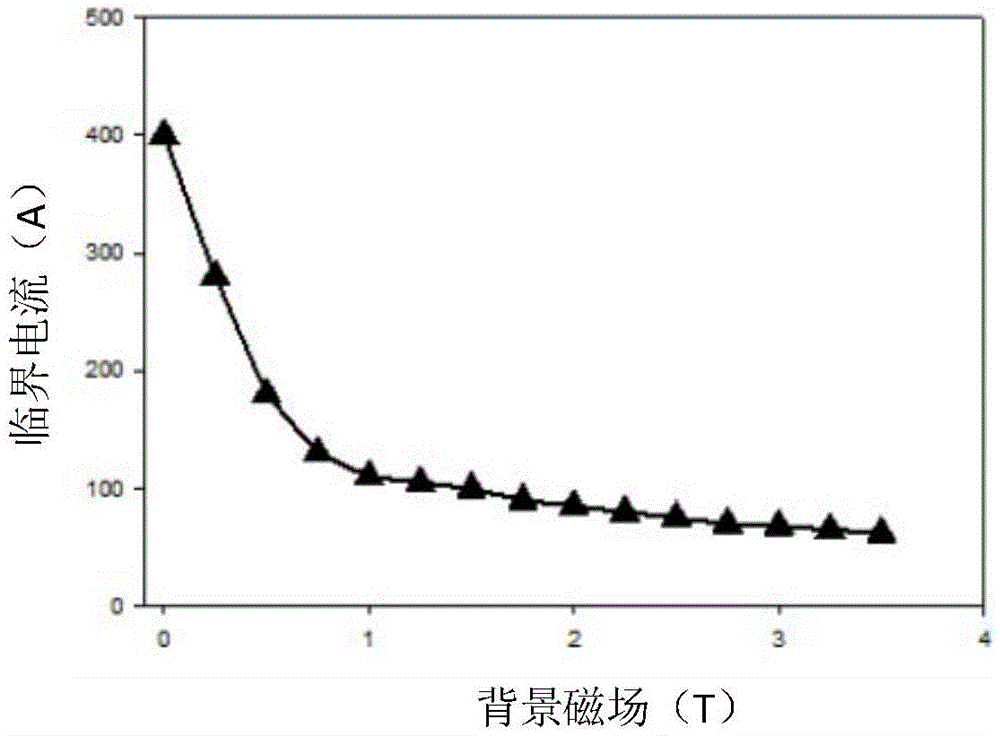

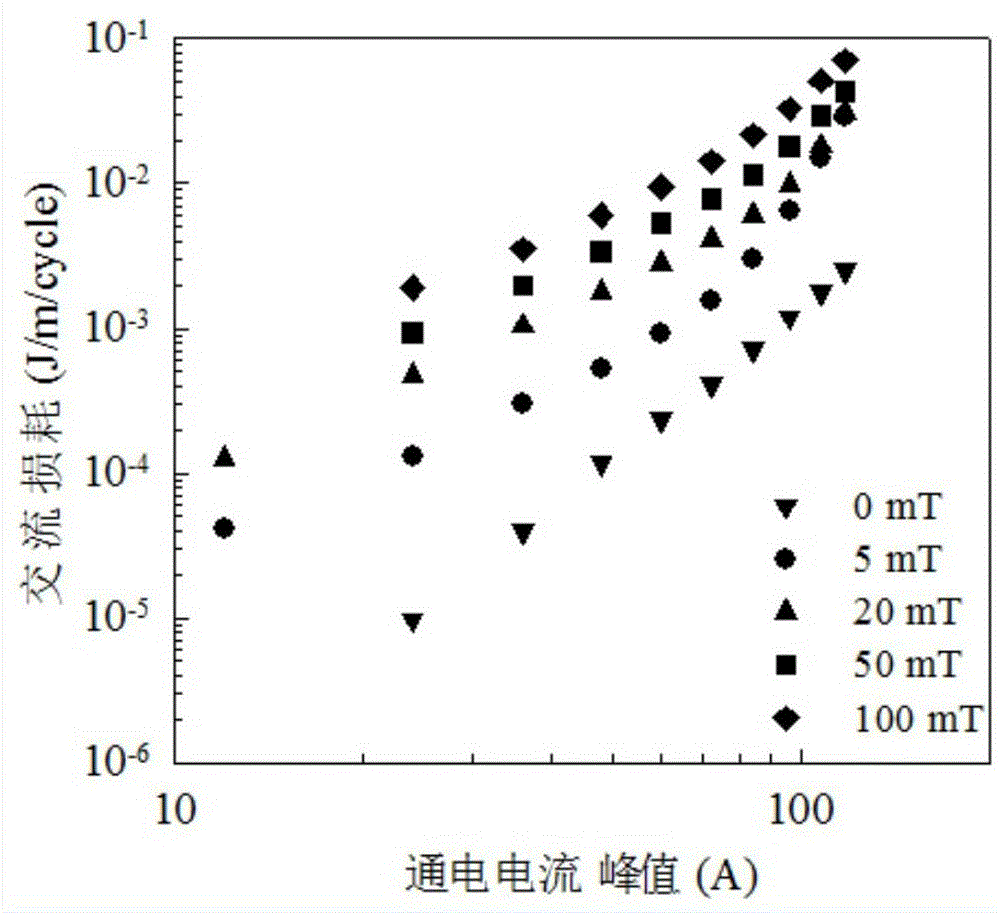

[0044] Embodiment 1: Applicable to the winding of pie-shaped superconducting coils. Compared with the traditional method, the critical current of the pie-type superconducting coil wound by the new high-temperature superconducting wire with twisted structure can increase the critical current by 20% and reduce the AC loss by 40%.

Embodiment 2

[0045] Embodiment 2: Applicable to the winding of helical tube superconducting coils. The critical current of the wound helical tube superconducting coil can be increased by 30%, and the AC loss can be reduced by 50%.

Embodiment 3

[0046] Embodiment 3: It can be applied to high-current superconducting current leads and cables. It can increase the critical current of the equipment by 20% and reduce the AC loss by 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com