Device and method of field measurement of folding pipes on the basis of three-dimensional space shooting positioning technology

A technology of three-dimensional space and positioning technology, which is applied in the field of on-site measurement devices for closed tubes, can solve problems such as affecting the performance and work efficiency of measurement, increasing the cost of investment, and tedious operation process, and achieves great economic benefits and market value. Safe and reliable, accurate measurement, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

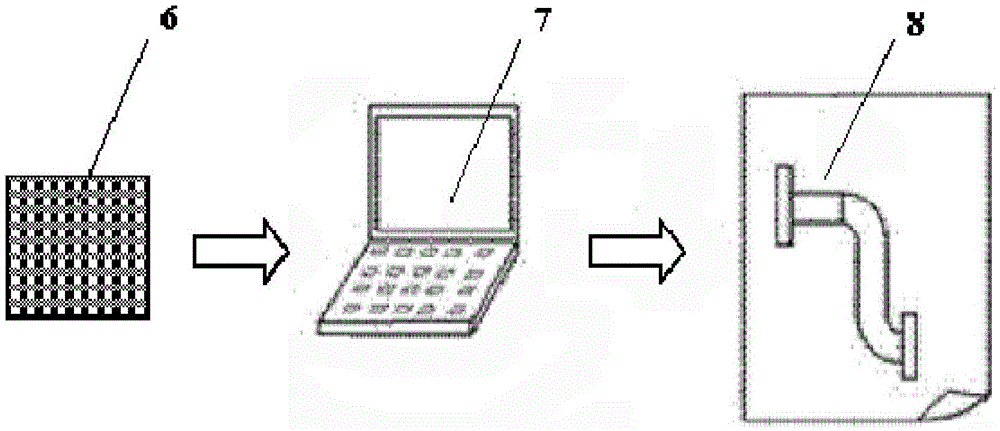

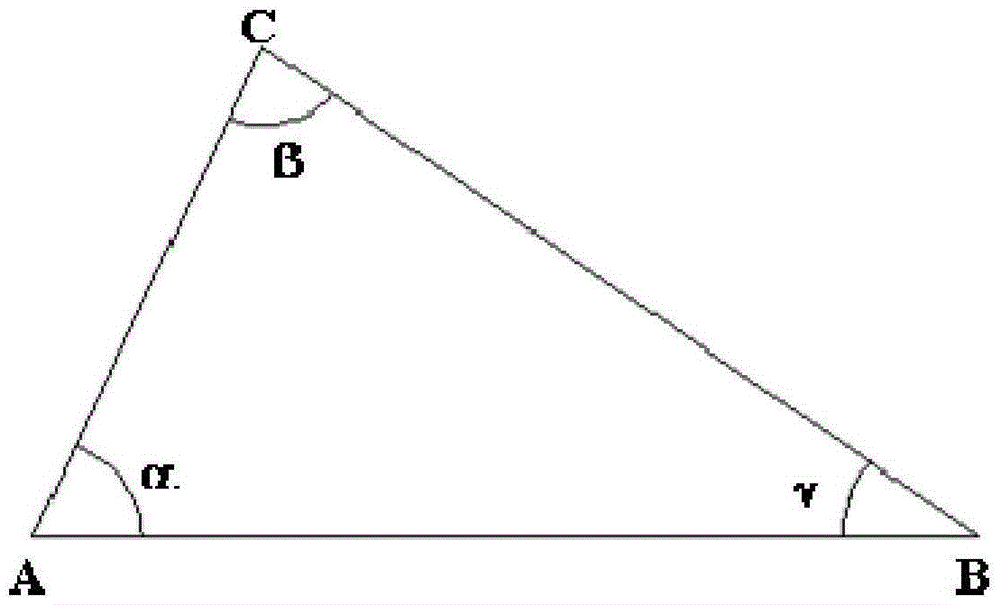

[0022] Such as Figure 1 to Figure 4 As shown in the present invention, a kind of on-the-spot measurement device for closing pipes based on three-dimensional space shooting and positioning technology, the ends of the two closing pipes are respectively provided with a first flange 1 and a second flange 5, including a first high-definition camera 2, The second high-definition camera 4 and the telescopic rod 3 connecting the first high-definition camera 2 and the second high-definition camera 4 are respectively provided with three mutually perpendicular angle sensors on the first high-definition camera 2 and the second high-definition camera 4, and on the first flange 1 and the second flange 5 are respectively provided with several photosensitive sheets 9, and the first high-definition camera 2 and the second high-definition camera 4 are equipped with storage for taking pictures of the first flange 1 and the second flange 5 and angle sensor detection respectively. Data Acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com