High pressure gas fragmentation iron ore test device

A high-pressure gas, test device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of wear and tear of mechanical parts, large power consumption, serious problems, etc., and achieve the effect of low tensile strength, low cost, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects of the device easy to understand, the following will be described in detail in combination with specific diagrams.

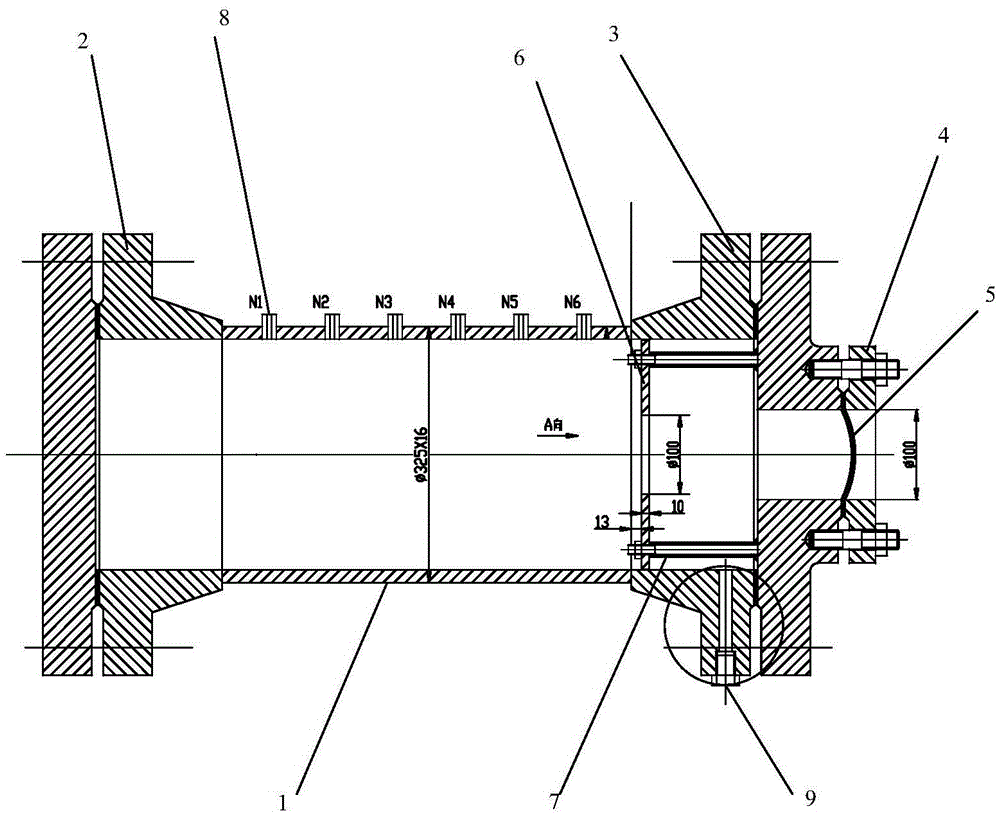

[0030] Such as figure 1 As shown, a high-pressure gas crushing iron ore test device includes: a steel drum 1, a first flange 2, a second flange 3, a sealing flange 4, an explosion-proof plate 5, an annular plate 6, a connecting rod 7, High pressure gas tank.

[0031] The two ends of the steel drum 1 are respectively provided with a first flange 2 and a second flange 3; the sealing flange 4 is arranged on the second flange 3; Between; the annular plate 6 is arranged between the second flange 3 and the steel drum 1, and the annular plate is connected with the second flange 3 through the connecting rod 7, so that an inflatable cavity is formed between the annular plate 6 and the second flange 3; A high-pressure gas tank (not shown) is connected with the steel barrel 1 through a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com