Substituted power line connecting structure for pins of discharge resistor for plastic coated aluminum LED (light-emitting diode) lamp

A discharge resistor, LED lamp technology, applied in the direction of light source, circuit layout, lighting device, etc., can solve the problems of LED lamp failure, aging of two wires, etc., to save space, solve aging, and reduce wage costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

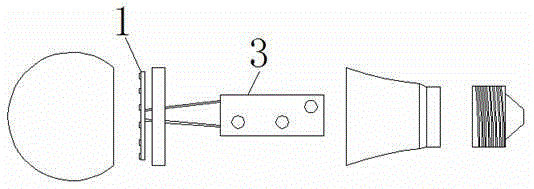

[0027] Such as figure 1 As shown, in the prior art, a plastic-clad aluminum LED lamp that uses electric wires to connect the internal drive power supply and the light source board includes a lamp holder, a plastic-clad aluminum part, a drive power supply, a heat sink plate, a light source board, and a lampshade. The drive power supply passes through two wires and The light source board is connected.

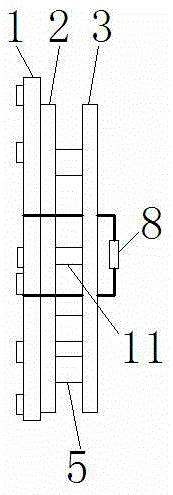

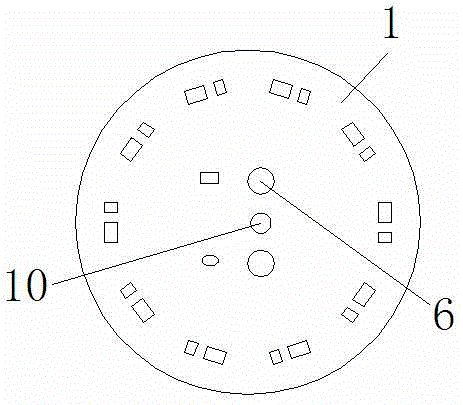

[0028] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the plastic-clad aluminum LED lamp of the present invention uses a discharge resistor pin instead of a power line connection structure, and it includes a light source board 1, an insulating board 2 and a driving power board 3, and the insulating board 2 is arranged on the light source board 1 and the driving power board 3. In the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com