Remote dust-free concrete sprayer

A concrete spraying machine, long-distance technology, applied in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of sealing failure, unreliable sealing structure, large pulse, etc., to increase the spraying distance, excellent sealing effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

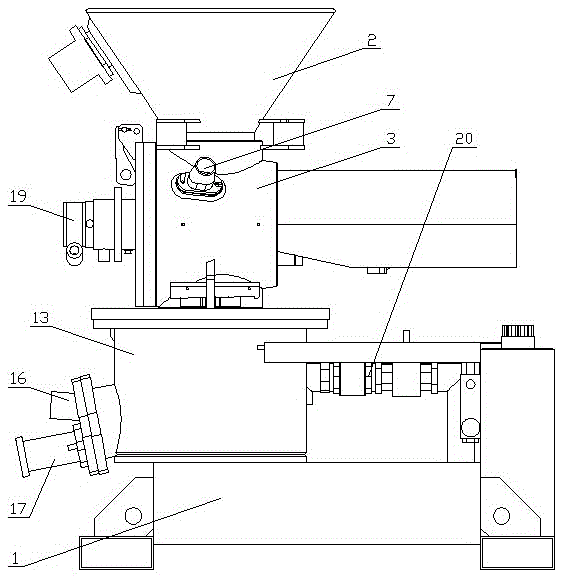

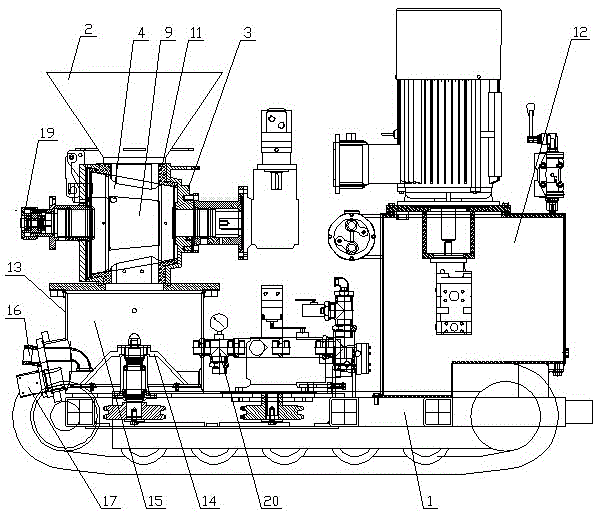

[0032] Attached below Figure 1-8 , the long-distance dust-free concrete sprayer of the present invention is described in detail below.

[0033] combined with figure 1 , 2 , the long-distance dust-free concrete spraying machine of the present invention, its structure comprises the trolley chassis 1 of crawler structure, the hopper part 2 that communicates successively from top to bottom, feeding part and spraying part, and drive feeding part and spraying material As for the power part of partial work, the spraying part is fixedly arranged above the trolley chassis 1, and the power part adopts hydraulic transmission.

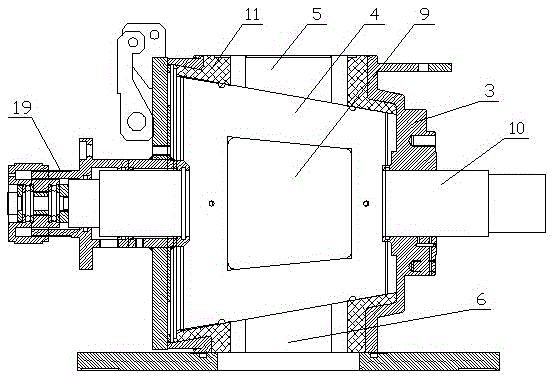

[0034] recombine image 3 , 4, 5, the feeding part includes a conical feeder, a dust removal system and an air path system 20; the conical feeder includes a feeding housing 3 and a feeding rotor 4, and the top of the feeding housing 3 There is a feed port 5 connected to the hopper part 2, a discharge port 6 connected to the spray part is opened at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com