Method for improving multi-cluster crack initiation effectiveness by blocking seams through multi-scale soluble balls

A multi-scale and effective technology, applied in the direction of mining fluid, earthwork drilling, sealing/isolation, etc., can solve the problem of low opening probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for improving the effectiveness of multi-cluster crack initiation by using multi-scale soluble balls to seal cracks, including the following steps:

[0026] Step 1) Drain the well using the drilling gauge: Drill the well to the artificial well bottom of the operating well to ensure that the wellbore is clean, check whether the inner diameter of the operating well is deformed or blocked, and if the operating well is deformed or blocked, repair the well;

[0027] Step 2) Perform multi-cluster perforation on the first section of the horizontal well;

[0028] Step 3) Fracturing construction using multi-cluster fracturing technology;

[0029] Step 4) Pumping pre-fluid and sand-carrying fluid;

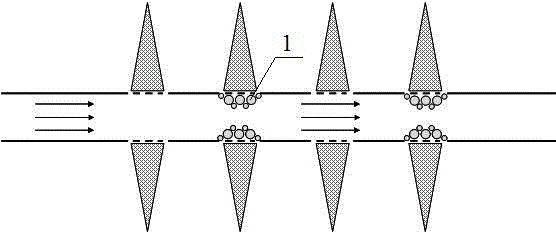

[0030] Step 5) Pump soluble balls 1 with particle sizes of 0.1mm, 1mm, 3mm, and 5mm through the fracturing fluid, the ratio is 2:1.8:3:0.8, and the volume fraction of soluble balls 1 in the fracturing fluid is 0.17;

[0031] Step 6) Soluble ball 1 ...

Embodiment 2

[0037] On the basis of Example 1, fire multi-cluster or hydraulic sandblasting multi-cluster perforation is used for horizontal wells; hydraulic bridge plug staged multi-cluster fracturing process or hydraulic sandblasting staged multi-cluster fracturing process is used for fracturing construction.

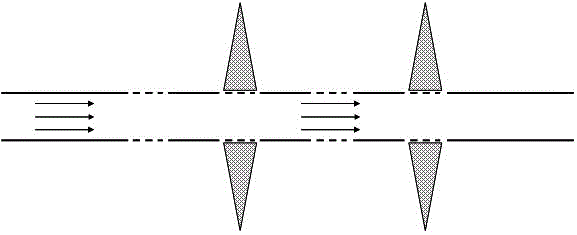

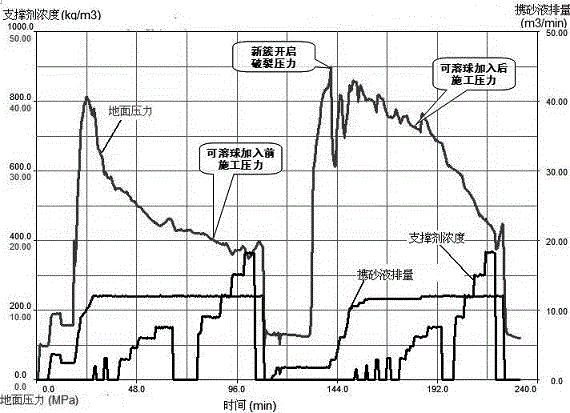

[0038] figure 1 Schematic diagram of partial perforation cluster opening for conventional horizontal wells; figure 2 It is a schematic diagram of multi-cluster opening of horizontal wells using multi-scale soluble balls 1 in the present invention; during fracturing construction, see proppant concentration, surface pressure and sand-carrying fluid discharge image 3 as shown, Figure 4 It is a schematic diagram of multi-clusters in horizontal wells after the self-dissolution of multi-scale soluble spheres 1.

[0039] The method provided by the present invention solves the problem that the opening rate of each cluster in each section of the existing horizontal well is relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com