Prefabricated assembly type shear wall vertical slit connecting structure and construction method thereof

A technology of prefabricated assembly and connection structure, applied in the direction of walls, building components, building structures, etc., can solve the problems affecting the integrity of the connection and the mechanical performance, the lack of the overall mechanical performance, and the difficulty in quality assurance, etc. Superior mechanical performance, poor restraint avoidance, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

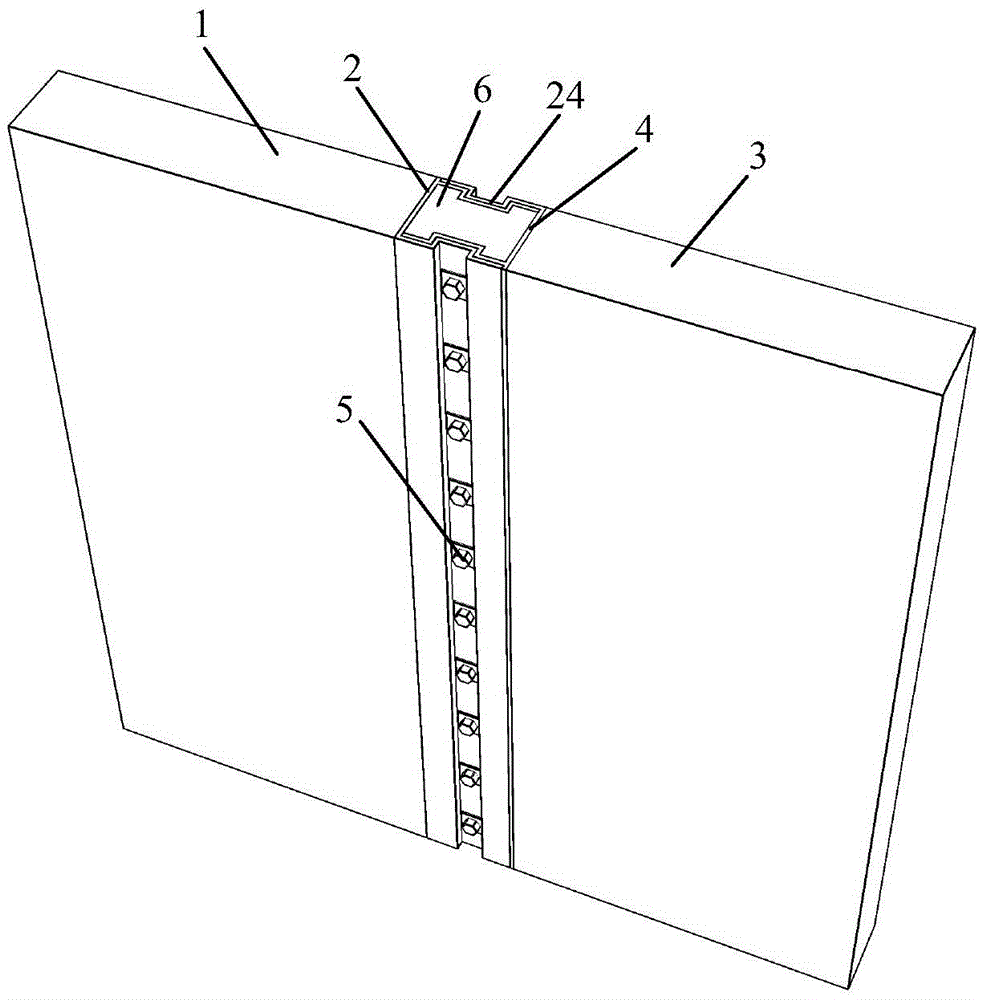

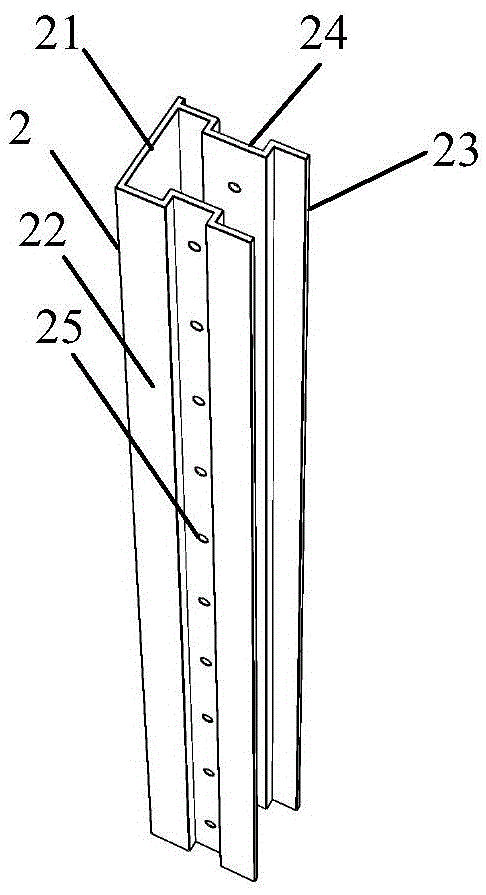

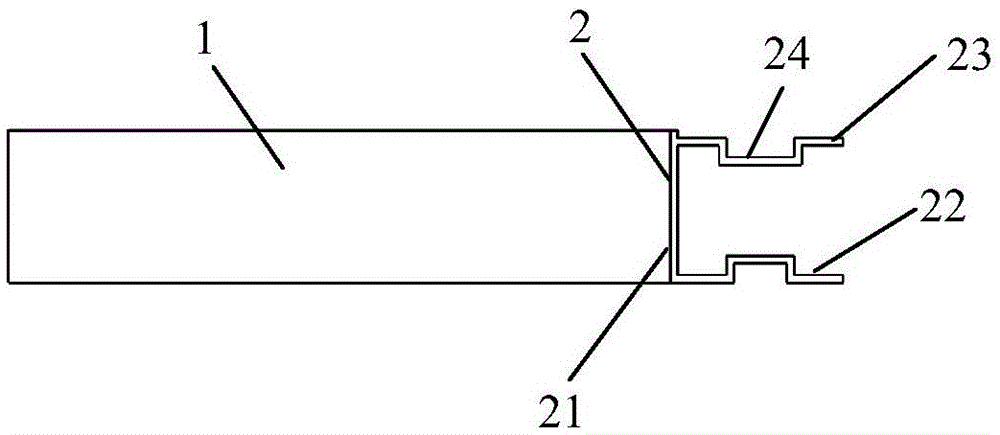

[0032] see Figure 1 to Figure 7 As shown, 1. A prefabricated assembly type shear wall vertical joint connection structure, including: left shear wall 1, left embedded steel 2, right shear wall 3, right embedded steel 4 and multiple Pull bolts 5; the left pre-embedded steel 2 is pre-embedded in the left shear wall 1; the right pre-embedded steel 4 is pre-embedded in the right shear wall 3; the left pre-embedded The embedded section steel 2 and the right embedded section steel 4 are placed between the left shear wall 1 and the right shear wall 3, and the left embedded section steel 2 and the right embedded section steel 4 have the same structure; The external left embedded steel plate 2 and the right embedded steel plate 4 are superimposed and arranged continuously along the height; the left embedded steel plate 2 includes: a side plate 21 directly connected with the left shear wall, a front side plate 22 and Rear side plate 23; The front side plate 22 and the rear side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com