An automatic retort pot cover opening equipment and brewing production line

A pot and pot lid technology is applied in the fields of automatic pot lid opening equipment and brewing production lines, which can solve the problems of high space requirement, large movement space, affecting work effect, etc., so as to ensure safe operation, high degree of intelligence, and economical efficiency. The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

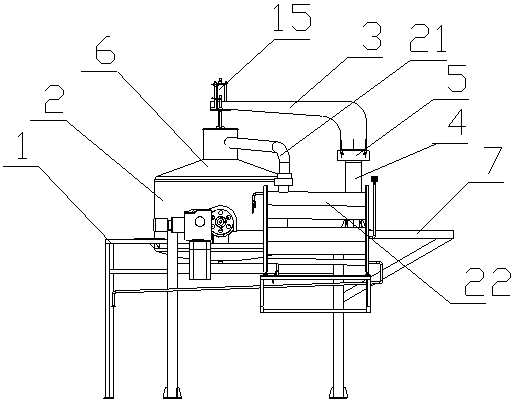

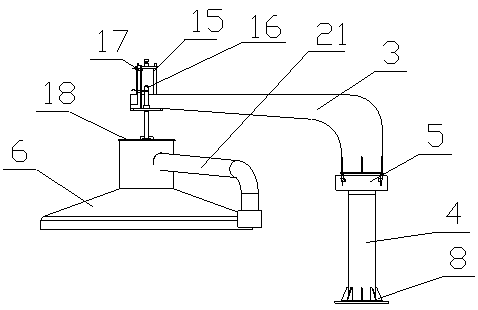

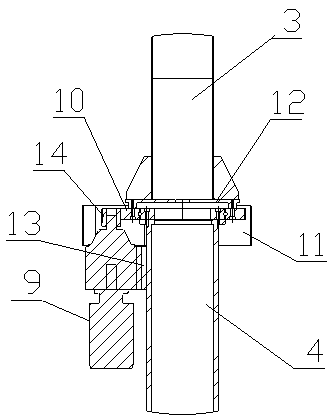

[0025] combine figure 1 A kind of automatic retort pot uncapping equipment shown, comprises workbench 1, retort pot 2, pot cover 6, uncapping device and control system, retort pot 2 is arranged on the workbench 1, and uncapping device is controlled by control system, The lid opening device includes a pot lid lifting assembly and a pot lid turning assembly. The pot lid turning assembly includes a swing arm 3, a column 4 and a swing mechanism 5. One end of the swing arm 3 is connected to the column 4 through the swing mechanism 5, and the swing arm 3 is connected to the column 4 through the swing mechanism 5. One end is connected with the pot cover lifting assembly, and the pot cover 6 is arranged on the position above the retort pot 2 through the pot cover lifting assembly.

[0026] In this embodiment, the workbench 1 is provided with a swing arm mounting bracket 7, and the bottom of the column 4 is provided with a fixing seat 8, which is fixed with the mounting bracket 7 by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com