Craft candle engraving machine

An engraving machine and candle technology, which is applied in the field of processing devices for engraving candle products with artistic aesthetics, can solve the problem of single color, etc., and achieve the effect of strong three-dimensional effect, beautiful appearance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

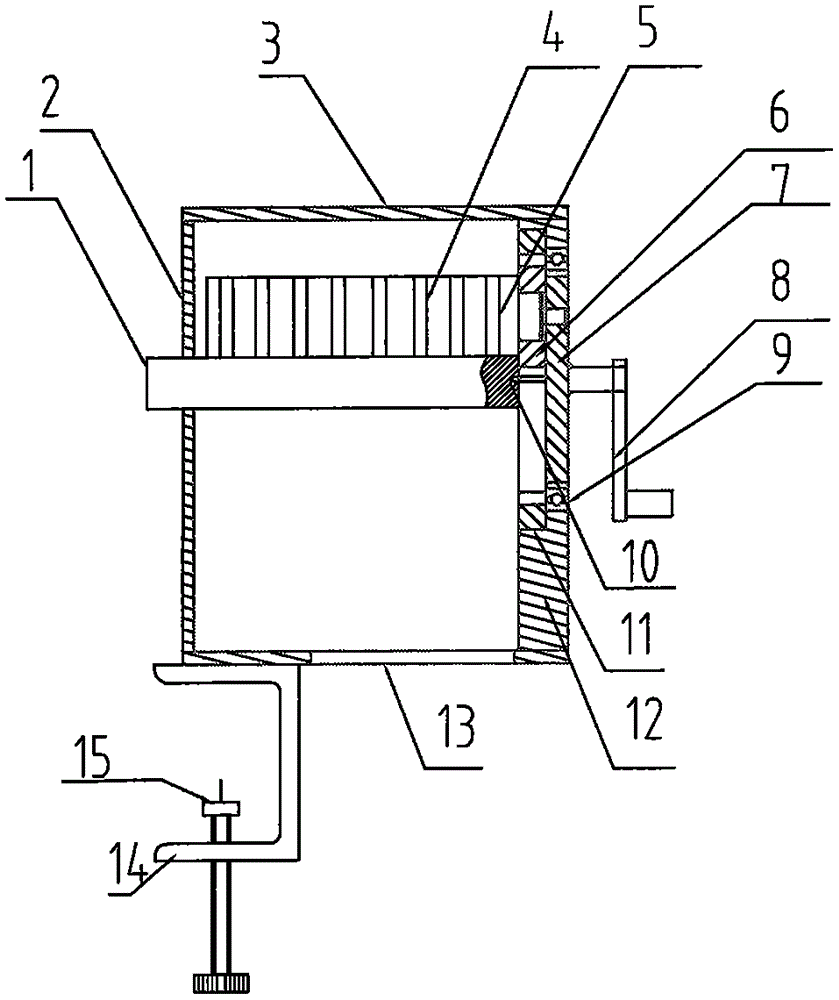

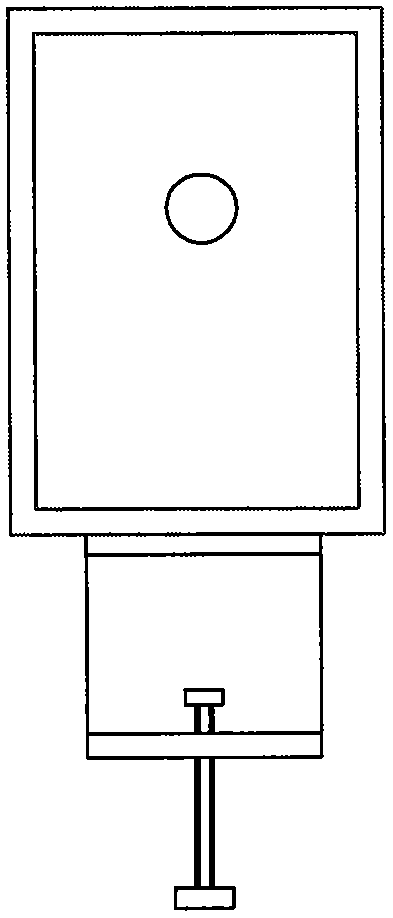

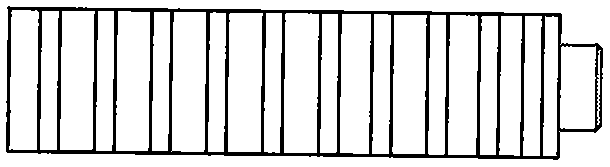

[0017] Such as figure 1 and figure 2 As shown, a craft candle engraving machine includes a square cylinder 3, the square cylinder 3 is blocked by a front end cover 12 and a rear end cover 2, the front end cover 12 is provided with a stepped hole, and the outer hole of the stepped hole A bearing 9 is installed inside, and an inner ring gear 11 is installed in the inner hole; the inner ring of the bearing 9 cooperates with the center wheel 7, and a thimble 10 is arranged on the axis of the inner end surface of the center wheel 7, and a gear 6 is also arranged at the eccentric position of the axis , the outer end surface is provided with a hand wheel 8 coaxial with the thimble 10; the teeth of the gear 6 form an internal mesh with the ring gear 11; the center of the gear 6 is installed with a roller shaft 4, and the roller shaft 4 is provided There are knife teeth 5; the rear end cover 2 is provided with a round hole coaxial with the thimble 10, and the round hole and the thimb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com