Quantum-dot epoxy resin composite colloid and fluorescent screen preparation method

An epoxy resin and quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as unfavorable production applications, complex structures, etc., and achieve the effects of long service life, high stability, and good optical conversion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Prepare quantum dot epoxy resin composite colloid according to the above components

[0069]

[0070] A mixed solvent of methyl ethyl ketone and methyl isoamyl ketone is used to assist the dissolution of the red quantum dot material and the green quantum dot material, and at the same time adjust the colloid to the required viscosity suitable for spraying.

[0071] The quantum dot fluorescent film is prepared on the substrate by spraying, and is cured by heating at 150° C. for 2 hours.

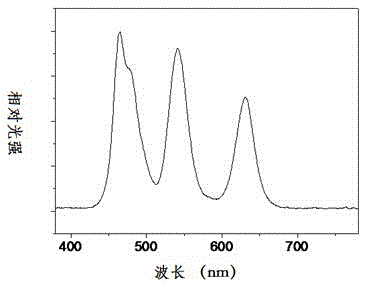

[0072] Excited by a blue light source with a wavelength of 450nm, the color coordinates of the obtained white light are (x=0.31, y=0.31), and the liquid crystal module prepared by using it as a backlight has good color expression. (low color temperature display)

Embodiment 2

[0074] Prepare quantum dot epoxy resin composite colloid according to the above components

[0075]

[0076] A mixed solvent of sec-butyl acetate and xylene is used to assist the dissolution of the red quantum dot material and the green quantum dot material, and at the same time adjust the colloid to the required viscosity suitable for screen printing film making.

[0077] The quantum dot fluorescent film was prepared on the substrate by screen printing, and was cured by heating at 120° C. for 4 hours.

[0078] Excited by a blue light source with a wavelength of 450nm, the color coordinates of the obtained white light are (x=0.24, y=0.24), and the liquid crystal module prepared by using it as a backlight has good color expression. (high color temperature display)

Embodiment 3

[0080] Prepare quantum dot epoxy resin composite colloid according to the above components

[0081]

[0082] Toluene is used as a solvent to assist the dissolution of the red quantum dot material and the green quantum dot material, and at the same time, the colloid is adjusted to the required viscosity suitable for scraping.

[0083] The quantum dot fluorescent film was prepared on the substrate by scraping, and was cured by heating at 100° C. for 4 hours.

[0084] Excited by a blue light source with a wavelength of 450nm, the color coordinates of the obtained white light are (x=0.26, y=0.26), and the liquid crystal module prepared by using it as a backlight has good color expression. (medium-high color temperature display)

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com