Coating liquid for promoting infrared laser absorption capacity on ceramic, preparation method and application thereof

An absorption capacity and infrared laser technology, which is applied in the field of coating solution and preparation and application to promote the absorption capacity of infrared laser to ceramics, can solve the problems of insufficient absorption rate of near-infrared laser processing ceramics, and achieve simple preparation, high absorption rate, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

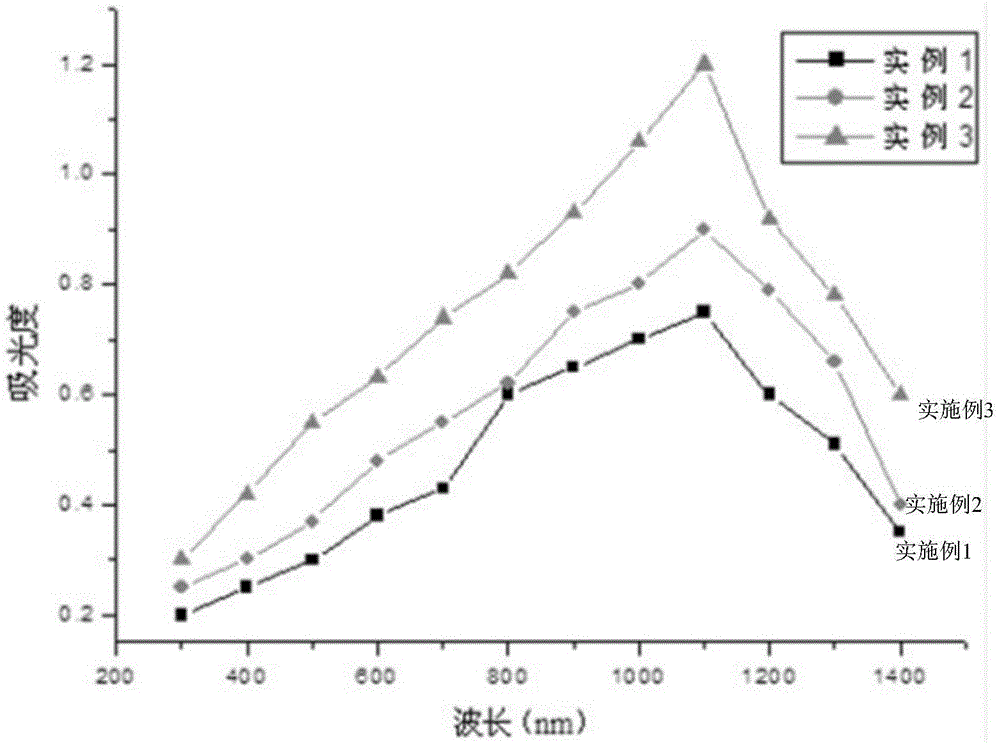

Image

Examples

preparation example Construction

[0030] The specific preparation process is as follows: first, mix and stir carmine and allura red according to the proportion of components; then, put the mixed powder into a vessel, add a solvent to the vessel for preparation, the solvent is water or alcohol, and mix well; Then, add the vessel to the magnet and put it on the magnetic stirrer. The magnetic stirrer has a heating temperature control device. Through heating and magnet rotation and stirring, the heating temperature is 40-50°C to dissolve the powder evenly and form a coating. solution.

[0031] In the specific application of the coating liquid that promotes the absorption ability of infrared laser to ceramics, the alumina substrate is placed flat on the carrier with adsorption holes, the ceramic plate is fixed on it, and the surface of the ceramic plate is coated with a dust-free cloth dipped in the coating liquid. cover.

Embodiment 1

[0033] First, mix 24% of carmine and 1% of allura red according to the distribution ratio of the components and mix and stir evenly; then, put the mixed powder into the container, add 75% water to the container for preparation, and mix evenly; then, put the container into the magnetic Put it on the magnetic stirrer. The magnetic stirrer has a heating temperature control device. The heating temperature is 40-50°C through heating and magnetic rotation stirring, so that the solid powder can be better and uniformly dissolved to form a coating solution.

Embodiment 2

[0035] First, mix 20% of carmine and 5% of allura red according to the distribution ratio of the components and mix and stir evenly; then, put the mixed powder into the beaker, add 75% alcohol to the beaker for preparation, and mix well; then, put the beaker into the magnetic Put it on the magnetic stirrer. The magnetic stirrer has a heating temperature control device. The heating temperature is 40-50°C through heating and magnetic rotation stirring, so that the solid powder can be better and uniformly dissolved to form a coating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com