Wastewater treatment device and treatment method aiming at metal surface treatment plant

A technology for metal surface treatment and wastewater treatment, applied in multi-stage water treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention provides a waste water treatment device and treatment method for metal surface treatment workshops. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

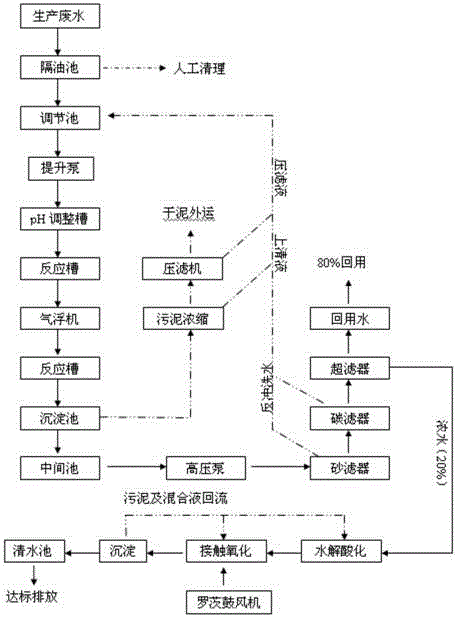

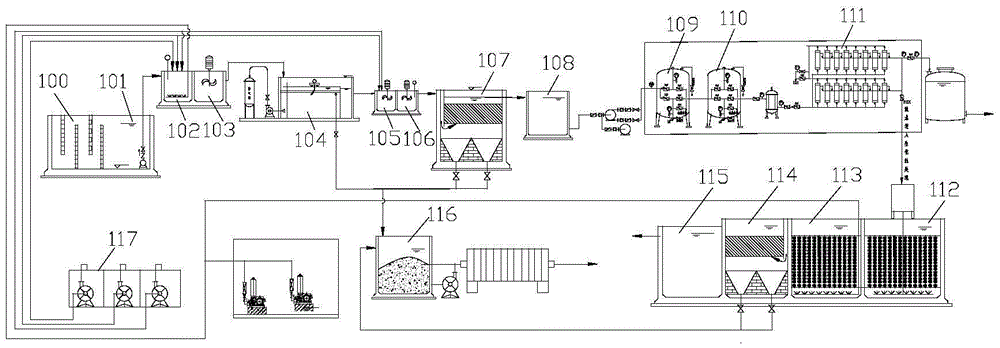

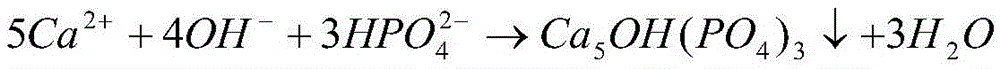

[0051] The invention provides a waste water treatment device for a metal surface treatment workshop, which is designed for the characteristics of the waste water generated by degreasing, pickling, surface adjustment and phosphating treatment of metal workpieces in the metal surface treatment workshop, and is suitable for metal surface treatment. Wastewater treatment plant in the workshop. After testing, the wastewater mainly contains oily substances, acids and bases, surfactants, phosphates and organic matter and other pollutants....

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com