Tobacco-waste-water processing technology

A technology for wastewater treatment and tobacco, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of high chromaticity, to achieve the effect of high degree of automation, lightening the load, and simplifying the processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

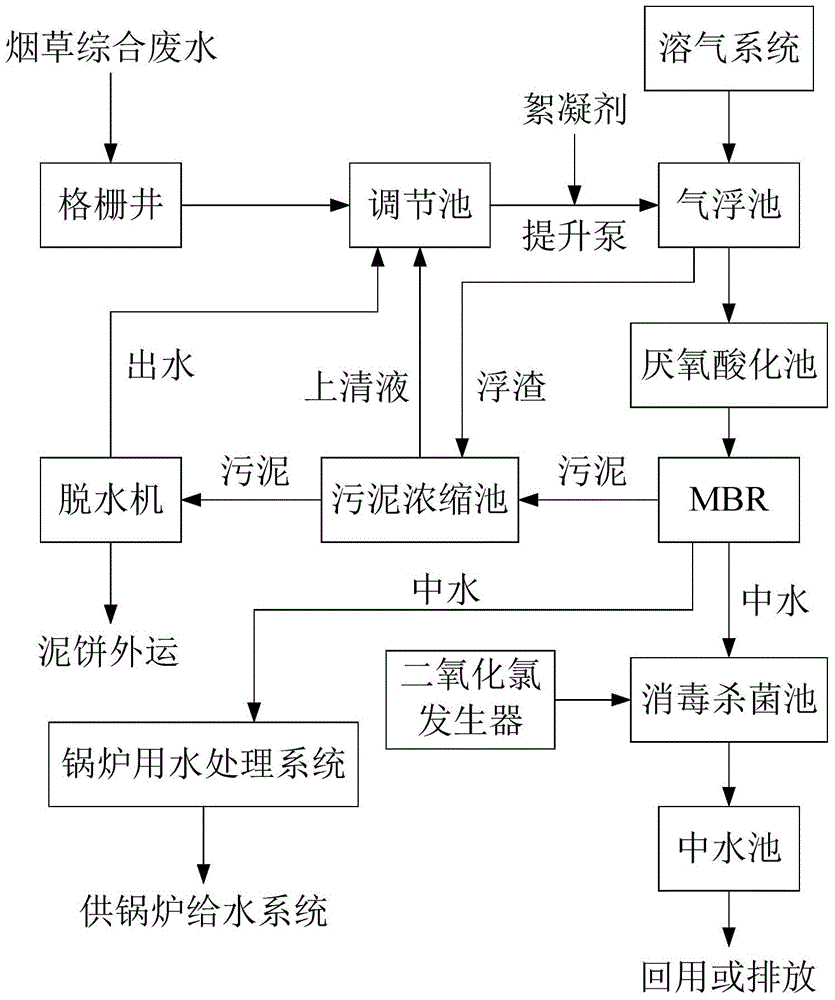

[0039] Such as figure 1 Shown is the flow chart of the tobacco wastewater treatment process in the embodiment of the present invention.

[0040] The tobacco wastewater treatment process of the present embodiment comprises the following steps:

[0041] S1. Tobacco comprehensive wastewater is introduced into the grid well for primary filtration. Tobacco comprehensive wastewater includes vacuum moisture resurgence, loose moisture resurgence, expanded tobacco shreds, stem washing, flavoring and feeding process drainage in the tobacco factory's silk workshop, and the cooling cycle including the power workshop. Water system drainage, boiler blowdown, domestic sewage.

[0042] As a common pretreatment equipment, the grille is used in various water treatment occasions. It mainly treats large suspended solids and floating substances in sewage, and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com