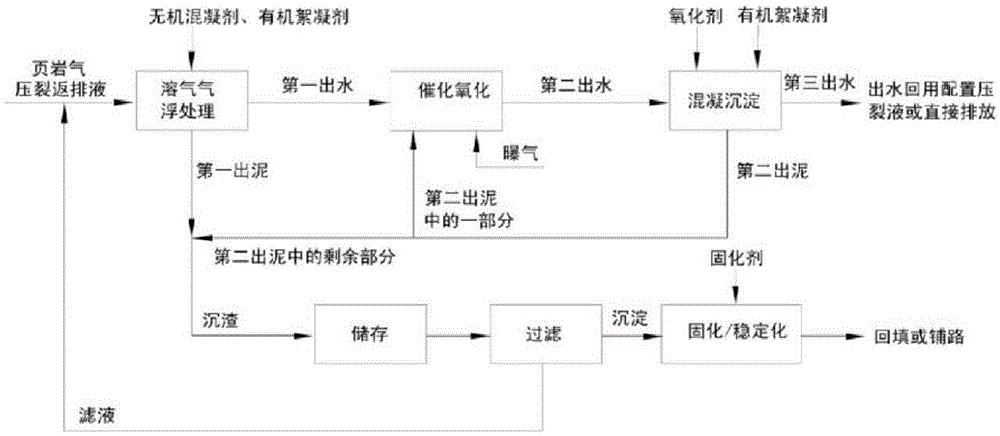

Shale gas fracturing outlet liquid treatment method

A treatment method and flowback liquid technology, applied in the direction of filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of cumbersome operation and complicated treatment process, and achieve the effect of simple process flow and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Shale gas pressure fracturing flowback fluid 1000mL, the appearance is dark green, there are oily substances on the surface, high suspended solids, pH 7.62, COD Cr Is 15118mg / L, TDS is 13823mg / L, SS is 2030mg / L, total alkalinity (in CaCO 3 Count) is 1304mg / L.

[0048] 1). Keep the pH value of the fracturing flowback fluid unchanged, perform dissolved air flotation treatment, adjust the air-water ratio to 3:1, adjust the bubble size to 30μm, and add 350mg of polyaluminum chloride at 150 revolutions / After stirring for 1 minute, add 8mg CPAM and 2mg APAM with a relative molecular mass of 10 to 20 million Daltons, continue to stir at 150 rpm for 1 minute, reduce the rotating speed to 35 rpm, stir After 30 minutes, stop the dissolved air flotation and stirring, and let stand for 30 minutes to obtain the first effluent water and the first mud;

[0049] 2) Adjust the pH of the first effluent to 3.0 with 0.01mol / L sulfuric acid, and send it to the catalytic oxidation reactor for ca...

Embodiment 2

[0054] Shale gas pressure fracturing flowback fluid 1000mL, the appearance is dark green, there are oily substances on the surface, high suspended solids, pH 7.62, COD Cr Is 15118mg / L, TDS is 13823mg / L, SS is 2030mg / L, total alkalinity (in CaCO 3 Count) is 1304mg / L.

[0055] 1). Keep the pH value of the fracturing flowback fluid unchanged, perform dissolved air flotation treatment, adjust the air-water ratio to 3:1, adjust the bubble size to 30μm, and add 500mg of polyaluminum sulfate at 150 rpm After stirring for 1 minute, add 15mg CPAM and 5mg APAM with a relative molecular mass of 10 to 20 million Daltons, continue to stir at 100 rpm for 1 minute, reduce the rotating speed to 35 rpm, and stir for 30 Minutes later, stop dissolved air flotation and stirring, and let stand for 30 minutes to obtain the first effluent water and sludge;

[0056] 2) Adjust the pH of the first effluent to 3.0 with 0.1 mol / L sulfuric acid and send it to the catalytic oxidation reactor for catalytic oxida...

Embodiment 3

[0061] Shale gas pressure fracturing flowback fluid 1000mL, the appearance is gray-brown, there are oily substances on the surface, the suspended solids are relatively high, the pH value is 8.25, COD Cr Is 4890mg / L, TDS is 12197mg / L, SS is 1330mg / L, total alkalinity (in CaCO 3 Count) is 978mg / L.

[0062] 1) Keep the pH value of the fracturing flowback fluid unchanged, perform dissolved air flotation treatment, adjust the gas-water ratio to 3:1, adjust the bubble size to 30μm, and add 800mg of polyaluminum ferric chloride at 150 revolutions After stirring for 3 minutes at the speed of rotation per minute, add 20 mg CPAM and 5 mg of APAM with a relative molecular mass of 10 million to 20 million daltons. After stirring at 150 rpm for 1 minute, reduce the rotation speed to 50 rpm. After stirring for 15 minutes, stop the dissolved air flotation and stirring, and let it settle for 30 minutes to obtain 860 mL of first effluent and first sludge;

[0063] 2) Adjust the pH of the first effl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com