Chromium-containing tannery wastewater treatment and resource utilization method based on natural biomass hydrogel

A technology of tannery wastewater and biomass, which is applied in animal processing wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve problems such as time-consuming and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

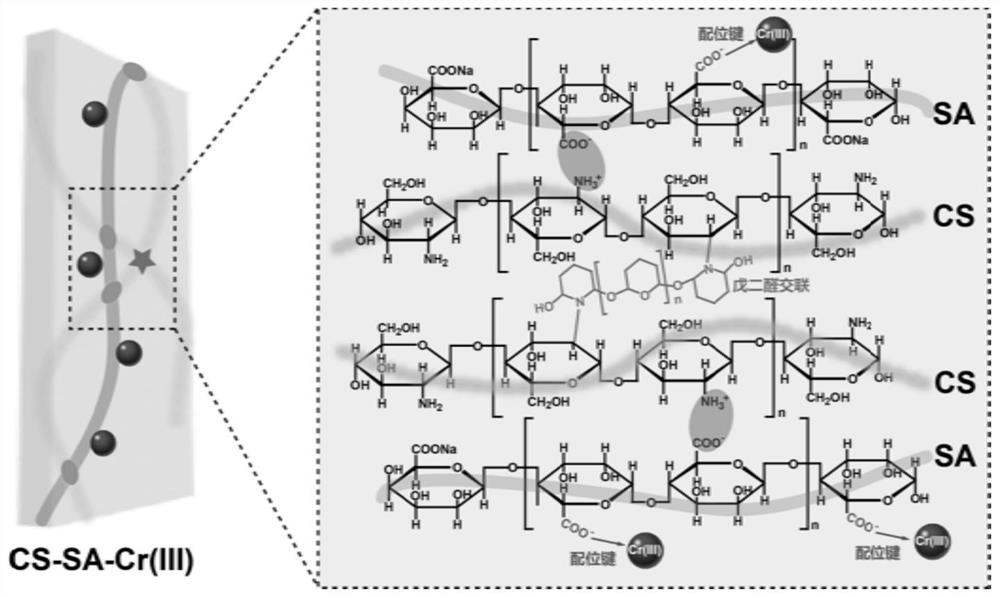

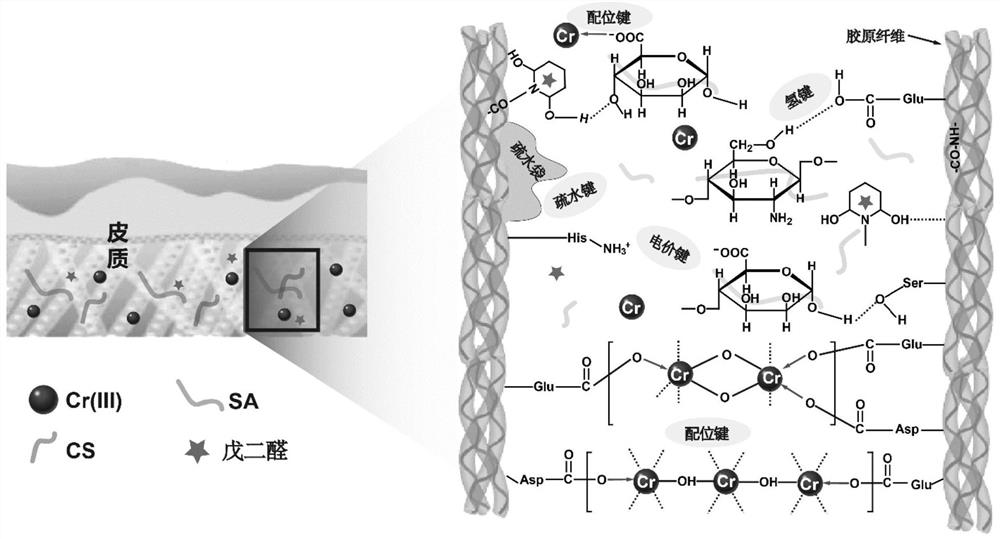

[0035] Step 1, preparation of CS-SA biomass hydrogel

[0036] Step 101, in parts by mass, dissolve 2 parts of sodium alginate (SA) in 100 parts of deionized water, and stir at 20°C for 40 minutes to obtain an SA solution; the viscosity of the sodium alginate is 180 Pa.s ;

[0037] Step 102, in parts by mass, dissolve 8 parts of chitosan (CS) in 200 parts of deionized water, and stir at 25°C for 60 minutes to obtain a CS solution; the viscosity of the chitosan is 400 mPa.s ;

[0038] Step 103: After uniformly mixing the SA solution obtained in step 101 and the CS solution obtained in step 102, add 2 parts of glutaraldehyde solution in parts by mass, and stir at 20°C for 10 minutes to obtain a slurry mixture Liquid; Described glutaraldehyde solution concentration is 25g / L;

[0039]Step 104. Put the slurry mixed liquid obtained in step 103 to stand under vacuum for 10 minutes, then pour it into a mold, expose the mold to a slow-release environment of glacial acetic acid, and r...

Embodiment 2

[0047] Step 1, preparation of CS-SA biomass hydrogel

[0048] Step 101, in parts by mass, dissolve 8 parts of sodium alginate (SA) in 200 parts of deionized water, and stir at 25°C for 60 minutes to obtain an SA solution; the viscosity of the sodium alginate is 220 mPa.s ;

[0049] Step 102, in parts by mass, dissolve 2 parts of chitosan (CS) in 100 parts of deionized water, and stir at 20°C for 40 minutes to obtain a CS solution; the viscosity of the chitosan is 200 Pa.s ;

[0050] Step 103: After uniformly mixing the SA solution obtained in step 101 and the CS solution obtained in step 102, add 4 parts of glutaraldehyde solution in parts by mass, and stir for 20 minutes at 25°C to obtain a slurry mixture Liquid; Described glutaraldehyde solution concentration is 25g / L;

[0051] Step 104. Put the slurry mixed solution obtained in step 103 to stand under vacuum for 20 minutes, then pour it into a mold, expose the mold to a slow-release environment of glacial acetic acid, an...

Embodiment 3

[0059] Step 1, preparation of CS-SA biomass hydrogel

[0060] Step 101, in parts by mass, dissolve 5 parts of sodium alginate (SA) in 150 parts of deionized water, and stir at 22°C for 50 minutes to obtain an SA solution; the viscosity of the sodium alginate is 200 mPa.s ;

[0061] Step 102, in parts by mass, dissolve 5 parts of chitosan (CS) in 150 parts of deionized water, and stir at 22°C for 50 minutes to obtain a CS solution; the viscosity of the chitosan is 300 mPa.s ;

[0062] Step 103. After uniformly mixing the SA solution obtained in step 101 and the CS solution obtained in step 102, add 3 parts of glutaraldehyde solution in parts by mass, and stir at 23°C for 15 minutes to obtain a slurry mixture Liquid; Described glutaraldehyde solution concentration is 25g / L;

[0063] Step 104. Put the slurry mixture obtained in step 103 under vacuum for 16 minutes, then pour it into a mold, expose the mold to a slow-release environment of glacial acetic acid, and react at 22°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com