Method for degrading phenol-containing wastewater by modified tio2 catalyst in a rotating disk reactor

A catalyst and reactor technology, applied in the field of modified TiO2 catalyst to degrade phenol-containing wastewater, can solve the problems of reducing the contact area between catalyst particles and organic pollutants, reducing the utilization rate of catalyst surface, and low utilization rate of carriers, and achieving convenient In-situ doping modification, reducing entrapment phenomenon, and improving the efficiency of light energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of pure TiO by sol-gel method 2 Catalyst sol, the specific ratio of raw materials is: butyl titanate: water: ethanol: hydrochloric acid: acetylacetone = 1: 3: 15: 0.05: 0.5 (ratio of substances); the preparation process is: first mix the total amount of raw materials and solvent Mix 2 / 3 of the total amount of water, catalyst, modified ions, and solvent to form liquid A; mix 1 / 3 of the total amount of water, catalyst, modified ion, and solvent to form liquid B; after stirring liquid A evenly, add liquid B drop by drop, Continue stirring for 0.5~2h after the dropwise addition to obtain a modified catalyst sol.

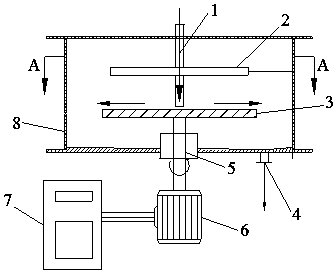

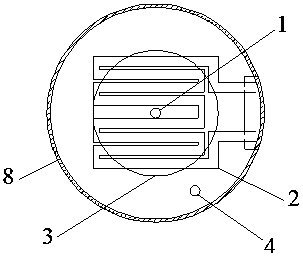

[0041] A rotating disk reactor is used for loading, and the rotating disk reactor is the rotating disk reactor described in the published patent CN103387272A. Such as figure 1 , 2 As shown, the turntable reactor includes a housing 8, a turntable 3, a rotating shaft 5, an excitation light source 2, a liquid inlet pipe 1 and a liquid outlet pipe 4, t...

Embodiment 2

[0050] Preparation of modified TiO by sol-gel method 2 For the catalyst sol, the molar ratio of each raw material is tetraisobutyl titanate: water: ethanol: nitric acid: acetylacetone: Fe=1:2:20:0.05:1:0.005.

[0051] Other operating steps are the same as in Example 1.

[0052] The carrier turntable is made of stainless steel, the diameter of the turntable is 200mm, 6 layers are loaded, the calcination temperature is 450°C, the temperature is kept for 1.5h, and the amount of loaded catalyst is 1.33g. Prepare 100mg / L phenol wastewater to simulate phenol-containing wastewater, and adjust to pH=7. Pour the wastewater into the storage tank, pump the wastewater into the rotating disk reactor through the flow meter, and return it to the storage tank under gravity for circulation after photocatalytic degradation. The light source adopts two linear ultraviolet lamps, the flow rate is 100L / h, the speed is 50rad / min, and the light intensity is 12mW / cm 2 , The degradation rate of phen...

Embodiment 3

[0054] Preparation of modified TiO by sol-gel method 2 For the catalyst sol, the molar ratio of each raw material is butyl titanate: water: isopropanol: hydrochloric acid: diethanolamine: V=1:1:10:0.05:0.5:0.01.

[0055] Other operating steps are the same as in Example 1.

[0056] The carrier turntable is made of stainless steel, the diameter of the turntable is 200mm, 3 layers are loaded, the calcination temperature is 500°C, the temperature is kept for 1h, and the amount of catalyst loaded is 0.48g. Prepare 100mg / L phenol wastewater to simulate phenol-containing wastewater and adjust to pH=4. Pour the wastewater into the storage tank, pump the wastewater into the rotating disk reactor through the flow meter, and return it to the storage tank under gravity for circulation after photocatalytic degradation. The light source adopts two linear ultraviolet lamps, the flow rate is 80L / h, the speed is 50rad / min, and the light intensity is 12mW / cm 2 , The degradation rate of pheno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com