Functional SFS nonwoven fabric with characteristics of ultraviolet ray resistance, permeation resistance and moisture permeation

An anti-ultraviolet and functional technology, applied in the direction of protective clothing, special outerwear, clothing, etc., can solve the problems of poor waterproof permeability, environmental pollution, easy tearing, etc., and achieve good moisture permeability, good UV shielding, Good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

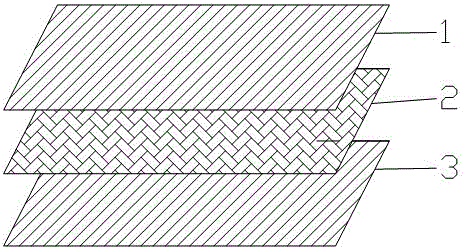

[0012] see figure 1 , a kind of anti-ultraviolet, anti-moisture permeation functional SFS non-woven fabric that the present invention relates to, it is made up of upper surface layer 1, middle layer 2 and lower surface layer 3, and described upper surface layer 1, lower surface layer 3 are spun The spun-bonded non-woven fabric is made of polypropylene and treated with UV protection; the middle layer is a microporous moisture-permeable film made of a mixed material of polyethylene and calcium carbonate.

[0013] The upper and lower surface layers are made of spun-bonded non-woven fabric, which can ensure a certain strength, good tear resistance and abrasion resistance; Moisture vapor permeability. The upper and lower layers of spun-bonded fabric are processed after UV protection, which has the function of UV protection, so that the SFS material has the function of UV protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com