a 3d printer

A 3D printer and print head technology, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve problems such as large vibration of the print head, vibration of printed objects, deformation of printed objects, etc., to achieve good load capacity and lighten The effect of increased print head weight and printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

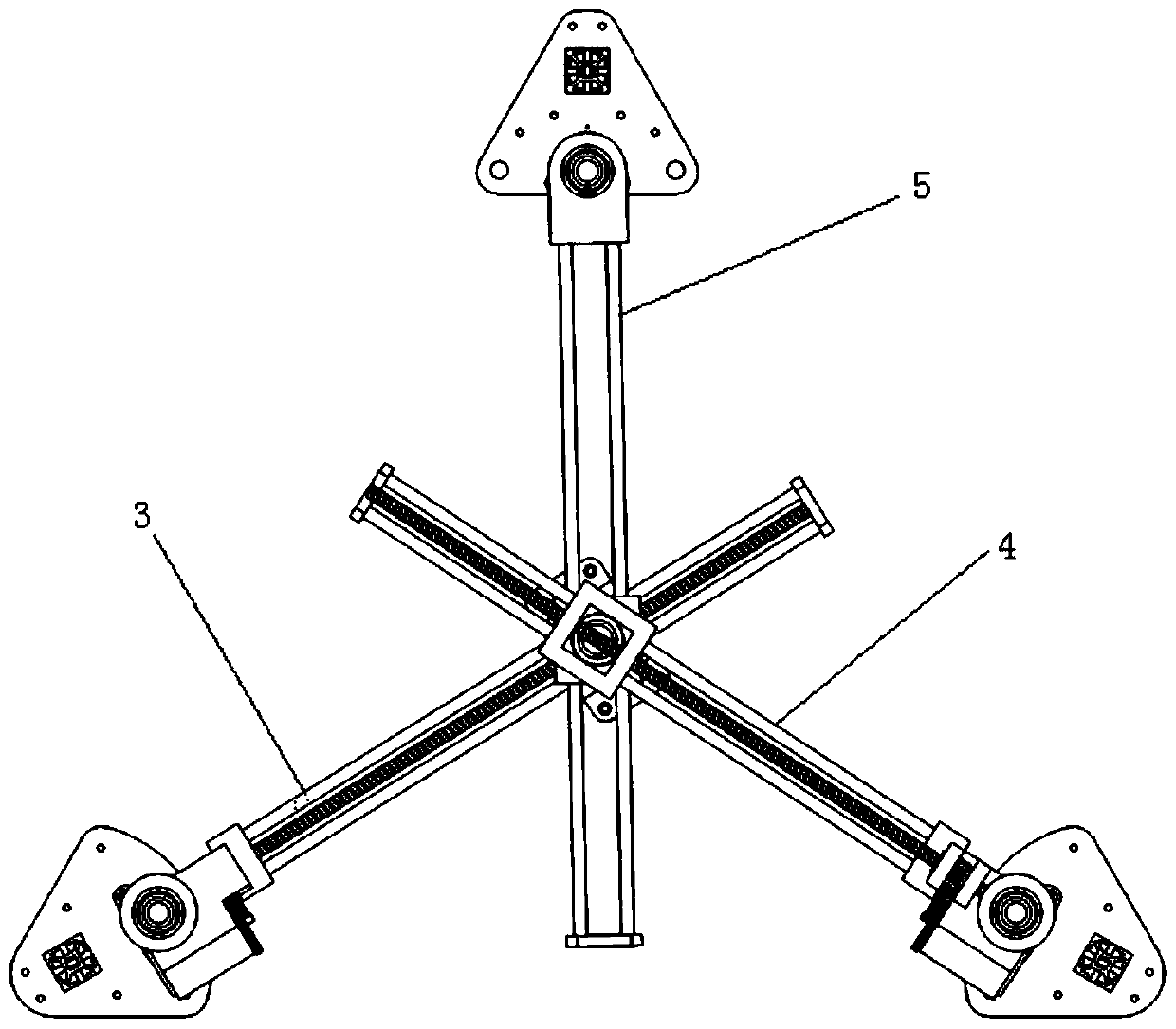

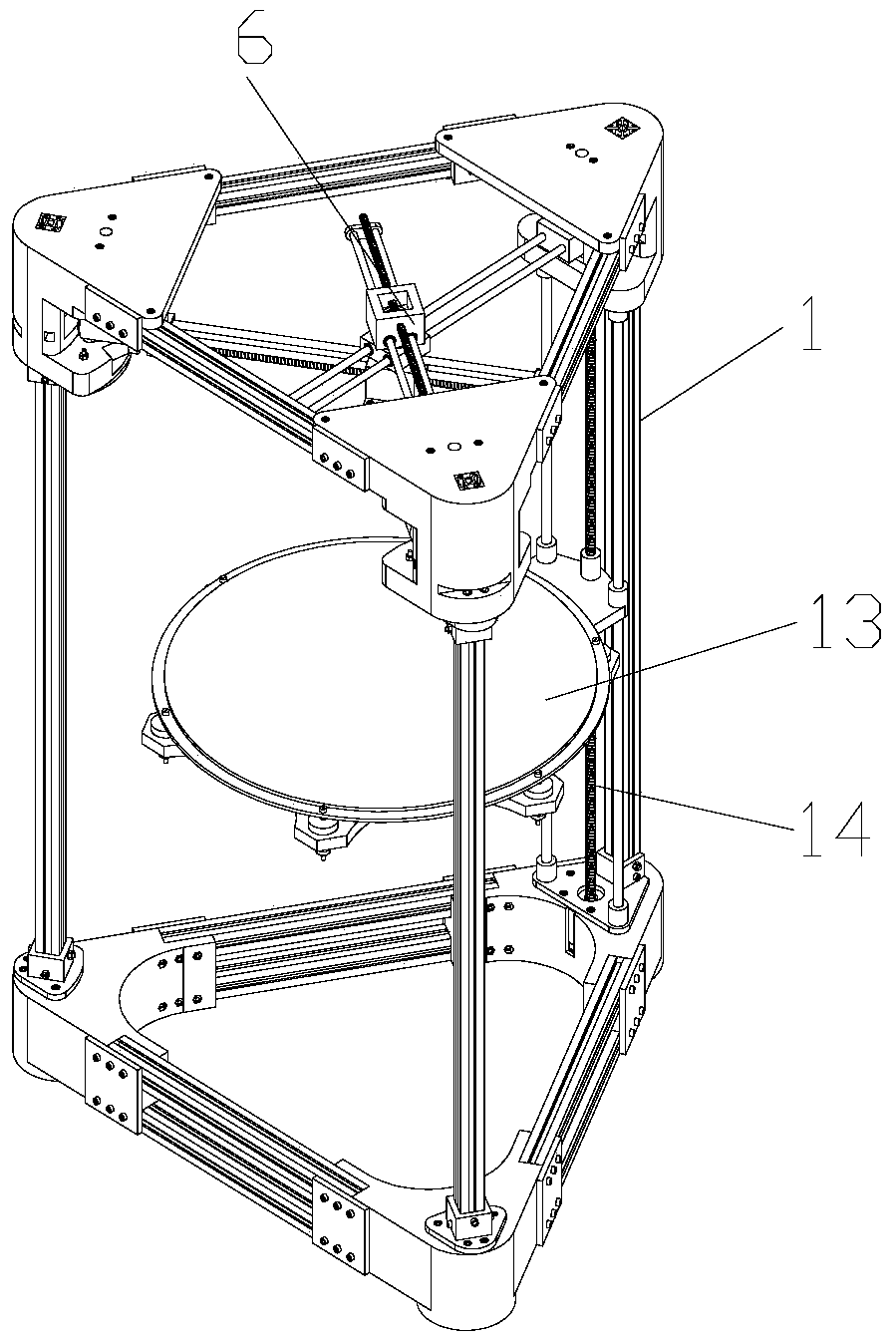

[0056] A 3D printer includes: a frame, a printing head, a plane driving mechanism, a printing platform, and an up and down driving mechanism.

[0057] The frame is a triangular column frame structure.

[0058] The planar drive mechanism includes: a first swing arm, a second swing arm, a third swing arm, a connecting body, a first position adjustment mechanism, and a second position adjustment mechanism. The first swing arm, the second swing arm, and the third swing arm all include a fixed end and a free end, and the three fixed ends distributed in a triangle are fixed on the frame through the rotating part, and the first, second, and third swing arms intersect The position of is the position where the connector is located. The connecting body includes the first sliding seat, the third sliding seat, and the second sliding seat arranged sequentially from top to bottom. On the connecting shaft, a locking screw is installed on the upper end of the connecting shaft, and a washer ...

Embodiment 2

[0066] In this embodiment, the first position adjustment mechanism and the second position adjustment mechanism have the same structure, both are swing drive mechanisms, including a motor, a transmission gear set, a herringbone gear and a spring or hairspring, the motor is fixed on the frame, and the herringbone The gear and the swing seat are fixed together; the motor drives the herringbone gear to rotate through the transmission gear set, the herringbone gear drives the swing seat to rotate, and the swing seat drives the first / second swing arm to rotate, so that the intersection of the first / second swing arm ( Connector) position is determined.

[0067] Figure 12 As shown, a backlash error elimination mechanism consisting of a spring and a herringbone gear is used. One end of the stretched spring is relatively fixed to the frame, and the other end is relatively fixed to the herringbone gear or the swing seat, so that the swing seat (together with the herringbone gear) ) al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com