Welding preheating device applicable to steel structures in various shapes

A preheating device and steel structure technology, applied in the field of steel structure welding, can solve the problems of long time spent, uneven preheating temperature at the welding preheating position, etc., to avoid potential safety hazards, improve safety, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

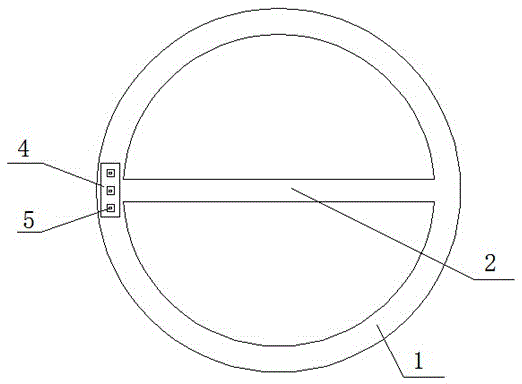

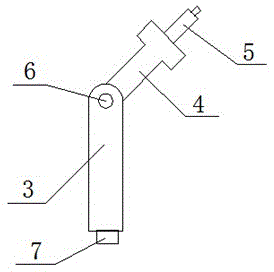

[0014] See figure 1 and figure 2 , a welding preheating device suitable for steel structures of various shapes, including a walking track with walking wheels at the bottom, a support beam 3 slidingly arranged on the walking track, and a T-shaped structure on the top of the support beam 3. Rotation positioning Beam 4 and a plurality of flame spray guns 5 that are fixedly arranged on the rotating positioning beam 4; The walking track includes a circular track 1 and a horizontal track 2 that is arranged on the inside of the circular track 1 and communicates with the circular track 1, and the horizontal track 2 Overlapping with the diameter of the circular track 1; the bottom end of the support beam 3 is provided with a slide block 7 that is slidably arranged on the walking track, and the drive mechanism of the slide block 7 and a plurality of flame spray guns 5 are all connected with an external controller; The bottom end of the positioning beam 4 is connected with the top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com