Movable impulse type compressed air soot blower and using method thereof

A compressed air, pulsed technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of accelerated catalyst deactivation, unstable use effect, low soot blowing intensity of sonic sootblowers, etc. Affecting the service life and the effect of stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

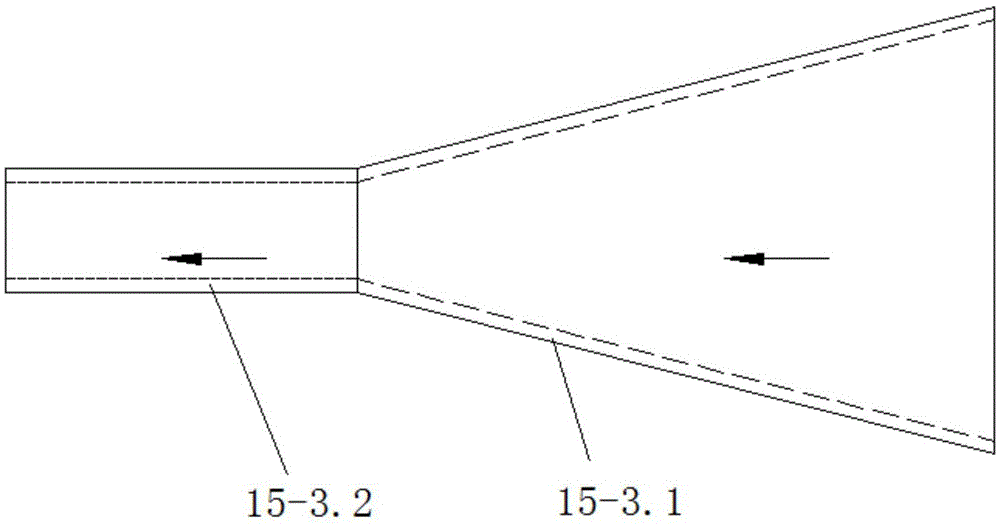

[0020] See attached picture:

[0021] Active pulse compressed air sootblower, including air compressor 1, air storage tank 2, the air outlet of air compressor 1 and the air inlet of air storage tank 2 are connected through the connecting pipe 3, and the connecting pipe 3 is installed in sequence from left to right There is a cold dryer 4, a filter 5, and a heater 6; the air outlet on the upper end of the outer wall of the gas storage tank 2 is connected with an upwardly bent air supply main pipe 7, and a manual main pipe is installed on the horizontal section of the air supply main pipe 7 from left to right. The control valve 8 and the pressure sensor 9 are connected with several spaced and horizontally distributed air supply branch pipes 10 on the longitudinal section. Each air supply branch pipe 10 is sequentially installed with the first manual branch control valve 11 and the stabilized air bag from left to right. 12. Electromagnetic pulse valve 13, the second manual branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com