Organic waste gas purification device and purification method aiming at shoe production plant

A technology of organic waste gas and purification equipment, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of ineffective treatment of waste gas, and achieve the effects of convenient comprehensive utilization, mature and reliable technology, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

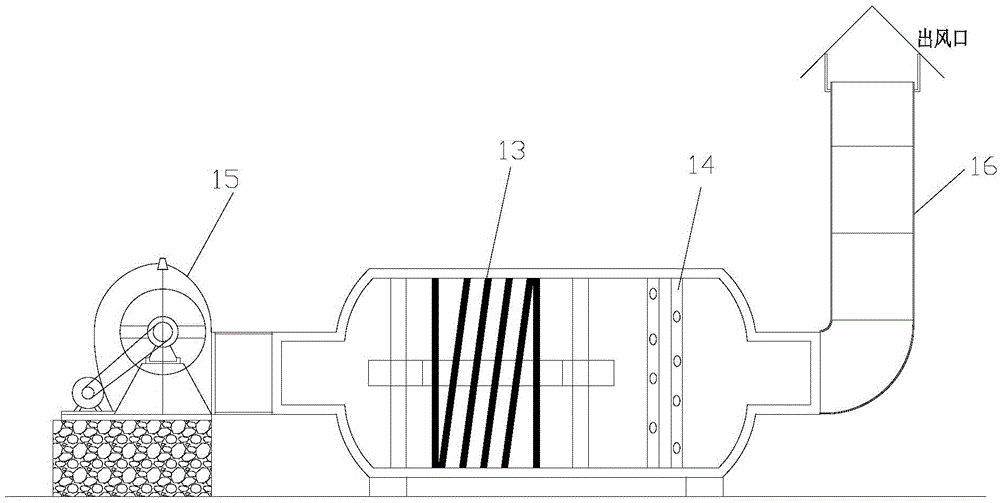

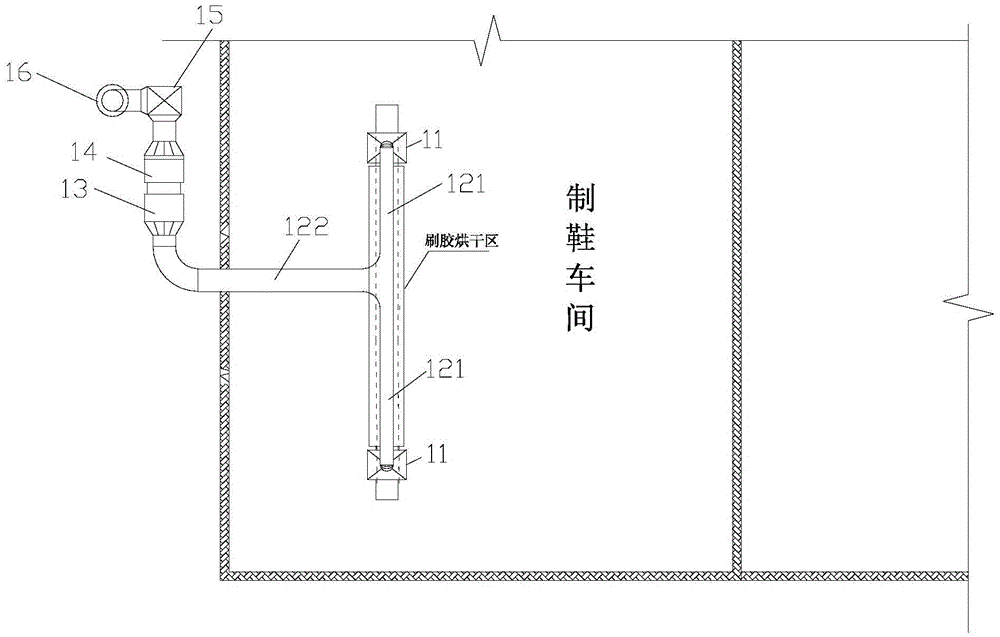

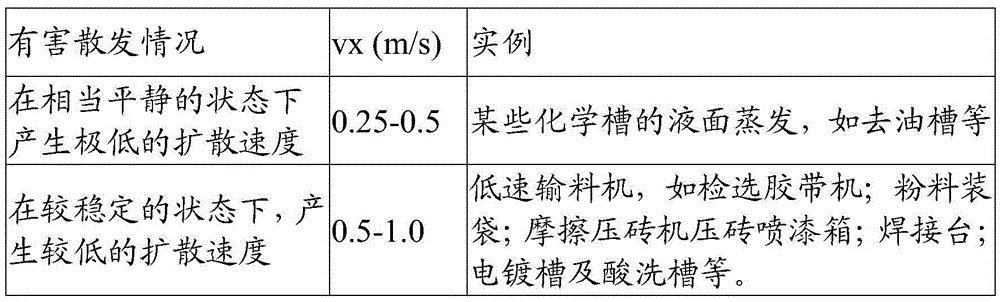

[0045] The production workshop of a shoe company, such as figure 2 As shown, there are 2 ovens, and the organic waste gas produced by the ovens diffuses into the atmosphere in a relatively stable state, so the control speed of the pollution source can be obtained according to Table 1 in "Air Pollution Control Engineering", which is between 0.5 and 1.0m / s In this design, vx=0.7m / s is selected. The amount of exhaust gas produced by the oven equipment is 8000m 3 / h (calculated as 8 hours per day), according to the actual situation on site, a set of organic waste gas purification device is designed for this waste gas treatment, and the processing air volume is 8000m 3 / Hour.

[0046] Table 1 External air collecting hood 11 controls wind speed vx

[0047]

[0048]

[0049] Since there are two ovens inside the car, two gas collecting hoods 11 are provided in the organic waste gas purification device of this embodiment, which are respectively arranged above the ovens. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com