Transfer device

A transfer device and driving device technology, applied in the direction of conveyor, transportation and packaging, non-mechanical conveyor, etc., can solve the problem of high cost of conveying elements and achieve the effect of small wear phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

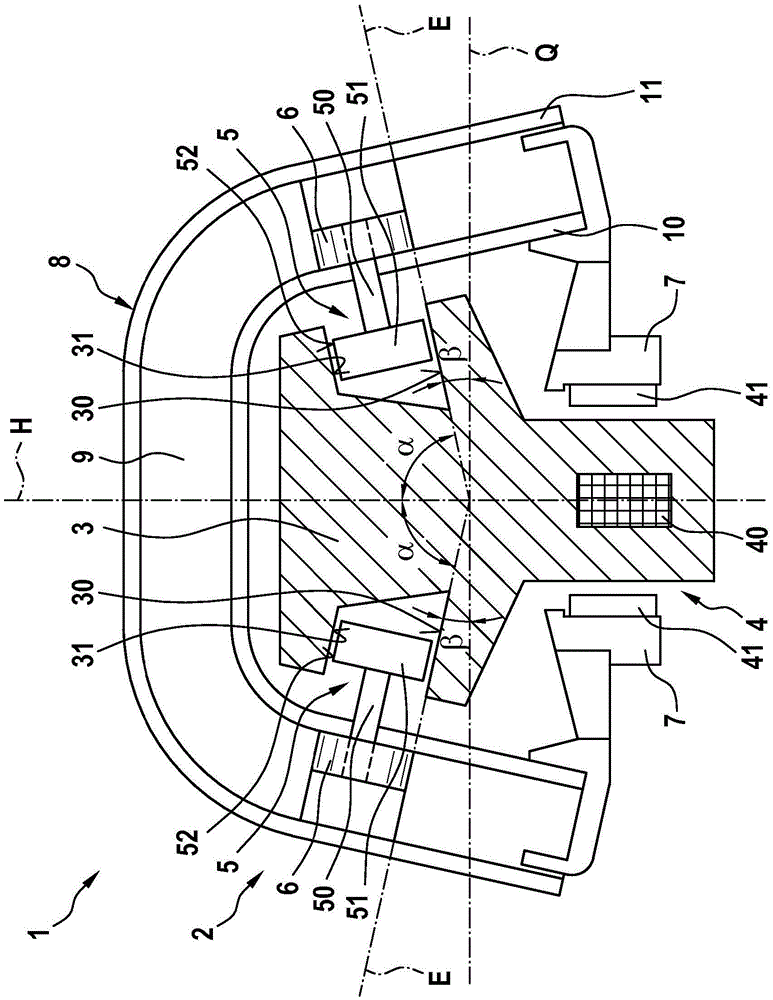

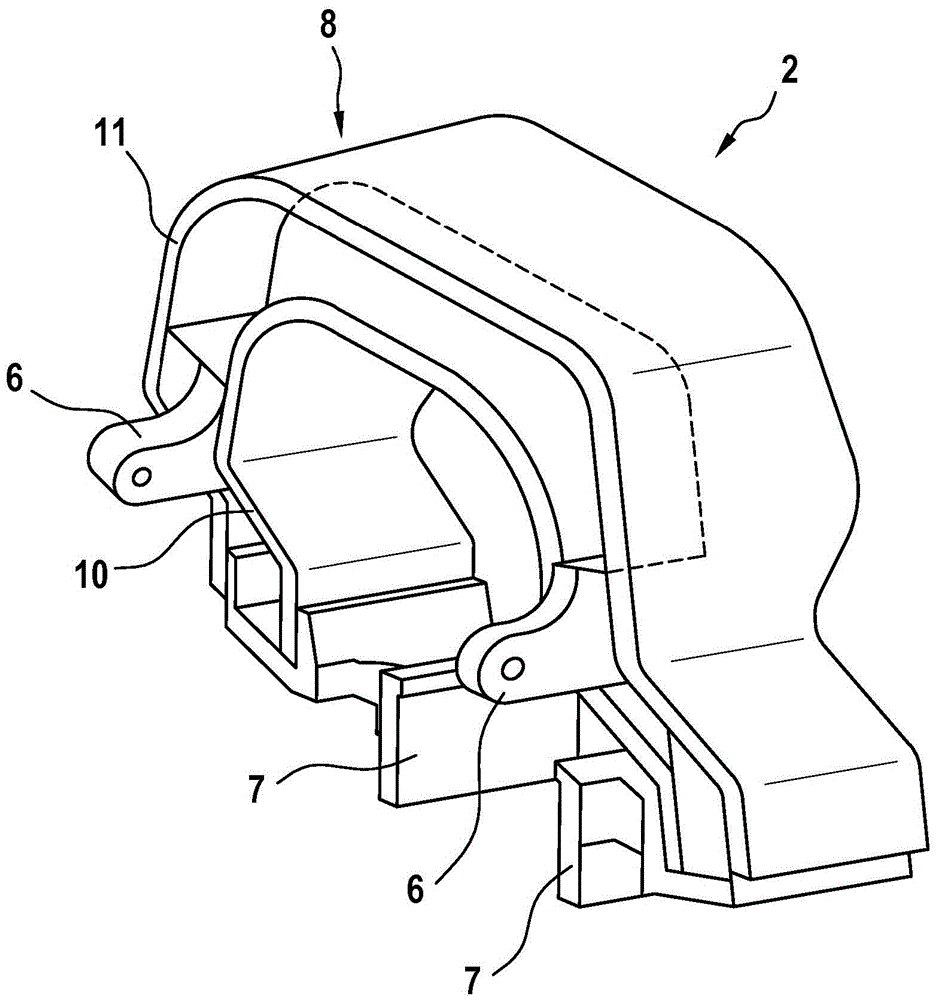

[0022] Refer to the following figure 1 and 2 A transfer device 1 according to a preferred embodiment of the present invention will be described in detail.

[0023] as from figure 1 As can be seen in the figure, the transfer device 1 according to the invention comprises at least one movable element 2 which is movable on a movement track 3 . The movement path 3 can be a circumferentially closed movement path or alternatively also a linear movement path. Preferably, a plurality of movable elements 2 , which can each be controlled individually, are arranged on the movement track 3 . Transfer devices of this type are used, for example, when feeding products to and / or transporting products from machines, especially packaging machines.

[0024] Furthermore, the transfer device 1 comprises a linear motor drive 4 comprising a coil 40 integrated into the stationary movement path 3 and a permanent magnet 41 , wherein the permanent magnet 41 is arranged on the movable element 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com