Touch screen, manufacturing method for touch screen, and touch apparatus

A production method and touch screen technology, which are applied in touch devices, touch screens and their production fields, can solve problems such as troublesome operation and tolerance, and achieve the effects of saving costs, small tolerances, and avoiding the introduction of tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

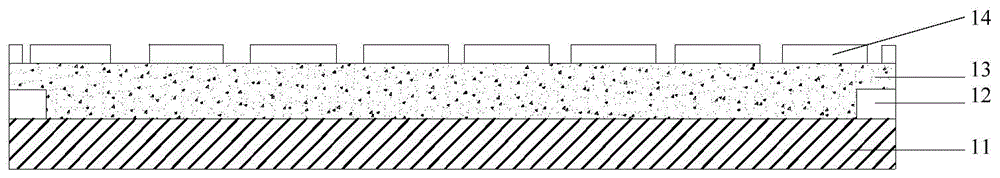

[0025] Set the touch screen that this embodiment makes is the touch screen of the full ITO product G1M structure of black, and its structure can refer to figure 1 and figure 2 . For a better understanding of the public, the inventors in figure 2 A partial enlargement of the depicted object is also drawn in . Such as figure 1 As shown, the touch screen includes a transparent substrate 11 , a decoration layer 12 , an anti-reflection film layer 13 , a transparent electrode layer 14 , and a flexible circuit board (not shown) on the transparent electrode layer 14 . Such as figure 2 As shown: 1A is the antenna area, 1B is the non-functional area, 1C is the isolated area, and 1D is the functional area.

[0026] (1) The transparent substrate 11 is provided. Choose strengthened silicate glass, the strengthening depth is about 8um. It is required that the spectral transmittance of the transparent substrate 11 at the wavelength position of 550 nm is greater than 91%. The trans...

Embodiment 2

[0033] Set the touch screen that this embodiment makes is the black G1F structure, and its structure can refer to image 3 and Figure 4 . For a better understanding of the public, the inventors in Figure 4 A partial enlargement of the depicted object is also drawn in . Such as image 3 As shown, the touch screen includes a transparent substrate 21, a decorative layer 22, an antireflection film layer 23, a transparent electrode layer 24, a silver paste conductive layer 25, an optically transparent adhesive layer 26, a thin film sensor 26, and a silver paste conductive layer 25 and a thin film A flexible circuit board (not shown in the figure) is placed between the sensors 26 . Such as Figure 4 As shown: 2A is the antenna area, 2B is the non-functional area, 2C is the ground line area in the silver paste conductive layer, 2D is the isolation area, and 2E is the functional area.

[0034] (1) The transparent substrate 21 is provided. Choose strengthened silicate glass, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com