High molecular material thermal stability tester

A technology of polymer material and thermal stability, applied in the field of polymer material thermal stability tester, can solve the problems of falling into the container, temperature deviation of material thermal stability, poor heating effect, etc., to achieve uniform heating and adjustment. Accurate, rapid heat transfer results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

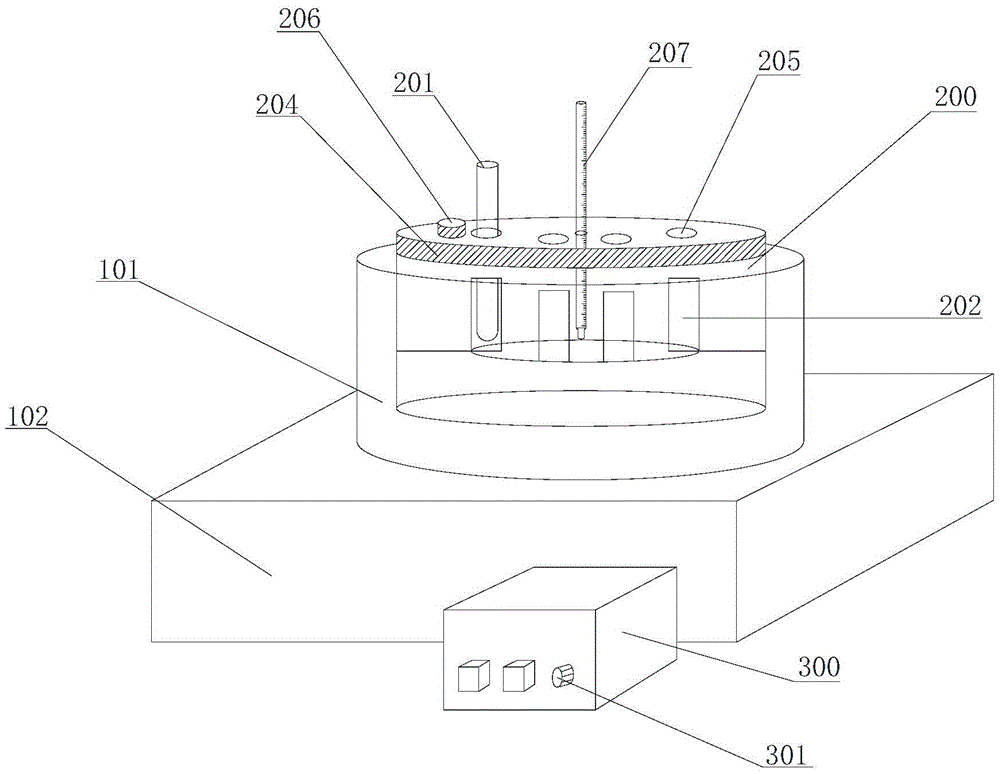

[0037] see figure 1 , figure 2 , image 3 and Figure 4 , this embodiment provides a polymer material thermal stability tester, the polymer material thermal stability tester is mainly used to measure the degree of difficulty of the chemical reaction of the polymer material under the condition of heating, by analyzing the difficulty To a certain extent, it can have a better evaluation of the performance of the polymer material, which can be used to judge whether the polymer material meets the standard.

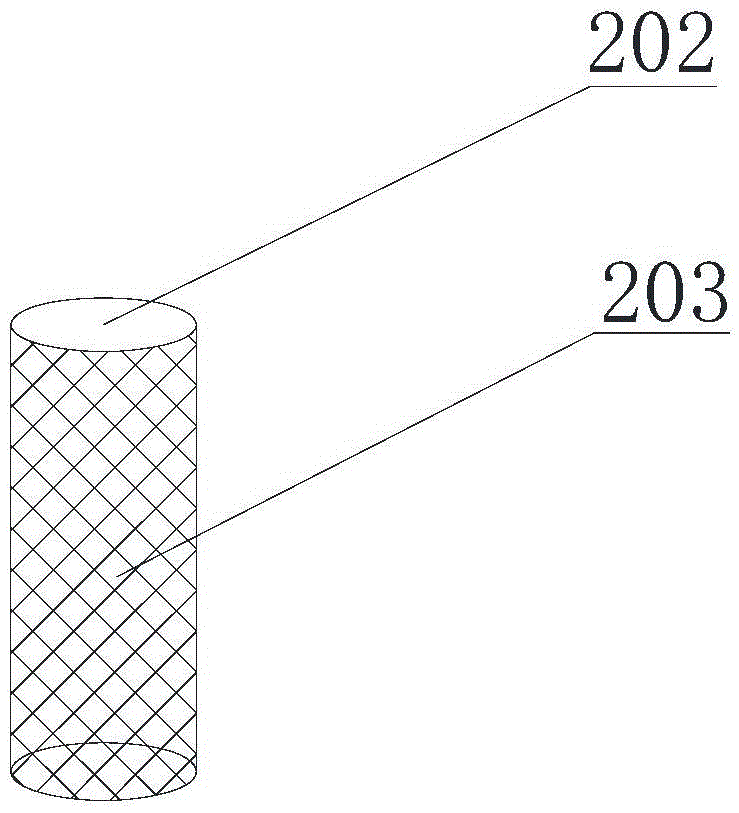

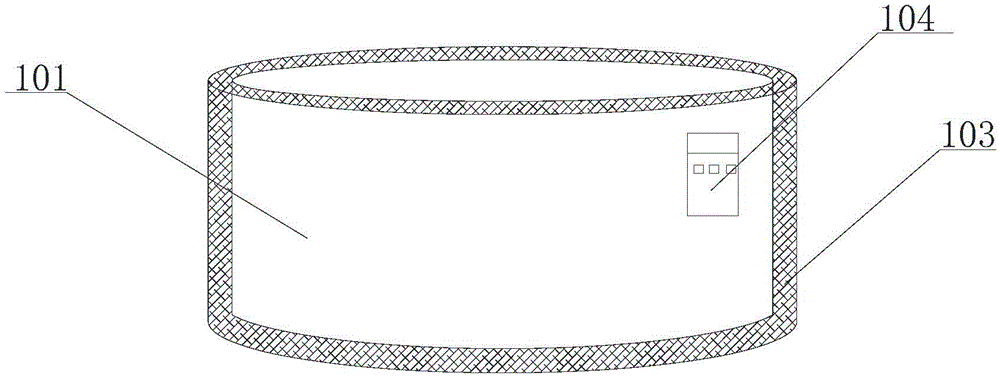

[0038] The macromolecular material stability tester provided in this embodiment includes a heating device, a container 200 and an electric control system 300. The heating device is provided with a heating body 101 and a vibrating table 102 for heating the container 200. The container 200 is used to hold liquid. The heating body 101 transfers heat to the container 200 to realize the purpose of heating the liquid in the container 200. By setting the heating body 101 on the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com