Active air-chamber structure and photoacoustic spectrometry gas sensing system

A technology of photoacoustic spectroscopy and gas sensing, which is applied in the direction of material analysis, measuring devices, instruments, etc. through optical means, can solve the problems of light source coupling and beam adjustment process complexity, poor stability, etc., to achieve improved optical power and structural stability Sex, reduce beam divergence, and facilitate extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

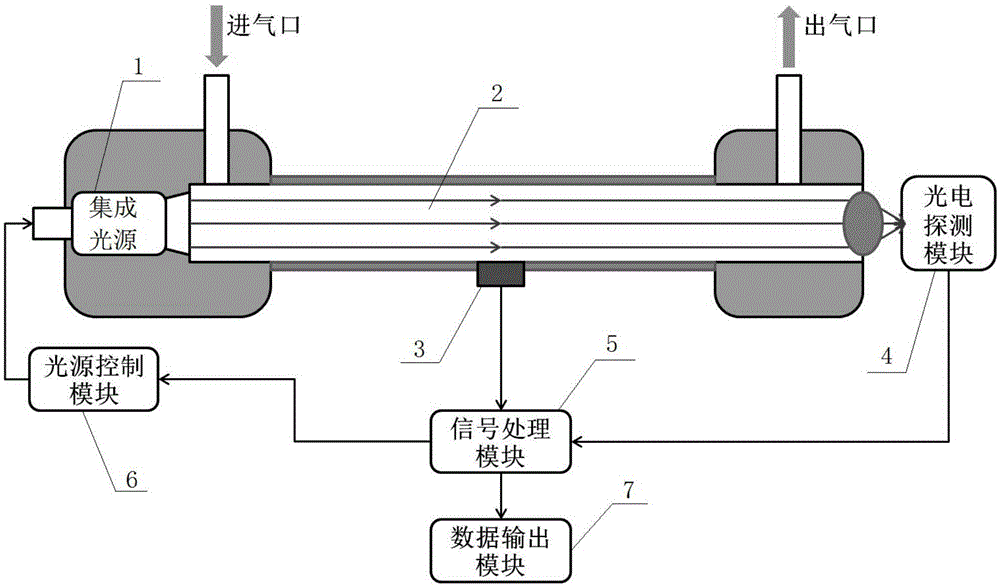

[0019] refer to figure 1 As shown, the active gas chamber structure and photoacoustic spectroscopy gas sensing system in this embodiment include a near-infrared DFB semiconductor laser 1, a photoacoustic cell 2, a microphone 3, a photoelectric detection module 4, a signal processing module 5, and a light source control Module 6 and data output module 7, the near-infrared DFB semiconductor laser 1 is directly packaged with one end of the photoacoustic pool 2 to form a photoacoustic gas chamber with a dumbbell-shaped structure as a whole (this structure can make the photoacoustic signal only propagate along the longitudinal direction, and the There is almost no change in the radial and angular directions, which is beneficial to the detection of photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com