Displacement Adjustment Method of Hole Distance of High Precision Composite Gauges

A combined gauge and displacement adjustment technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of bottom hole surface quality error, interference size error, fitter assembly qualified difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

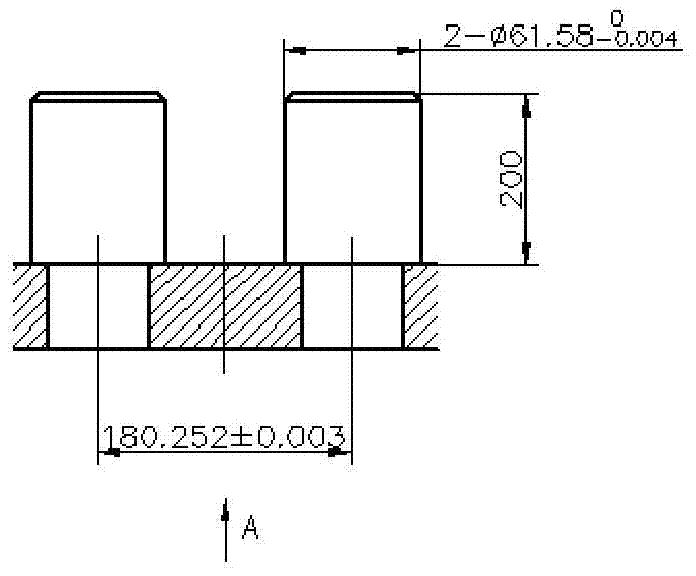

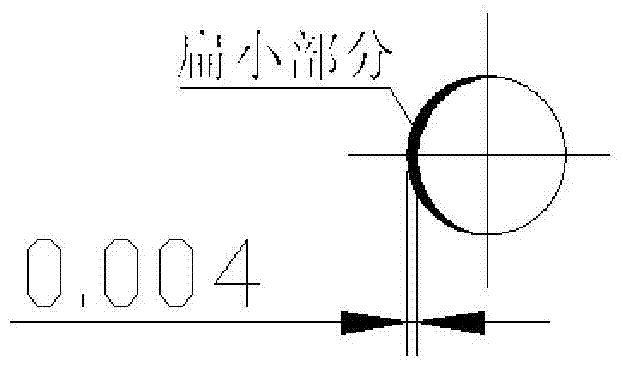

[0017] This embodiment takes figure 1 Take the two-hole position gauge shown as an example. The hole distance of the tested gauge is 180.262mm, the tolerance is 0.007mm larger, and the measuring column at the right end is 89°59′48″ relative to the bottom surface, the angle error is 12″, and the error direction is To the left, in order to make the measuring tool meet the design requirements, the "hole distance displacement adjustment method" of the present invention is used for adjustment. The specific steps are as follows:

[0018] Step 1: Select the left measuring column with relatively good perpendicularity to the bottom surface of the assembly as the positioning reference. It is necessary to adjust the right measuring column to the left along the dimension direction by 0.007-0.01mm, and at the same time ensure that the verticality is within 0.006mm;

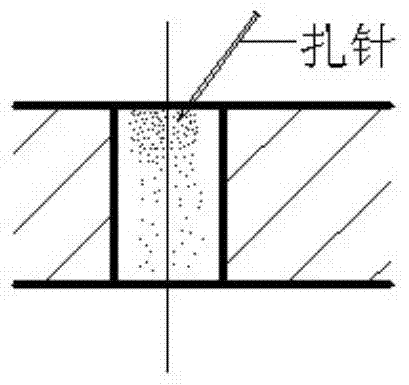

[0019] Step 2: Use a diamond file or oil stone to press the right measuring column into the end of the bottom hole, and trim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com