Spherical spraying nozzle desuperheater

A spherical nozzle and desuperheater technology, applied in the direction of superheating temperature control, steam superheating, steam generation, etc., can solve the problems of poor atomization effect, high energy consumption, low flow rate, etc., and achieve good atomization effect and contact Full, low-noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

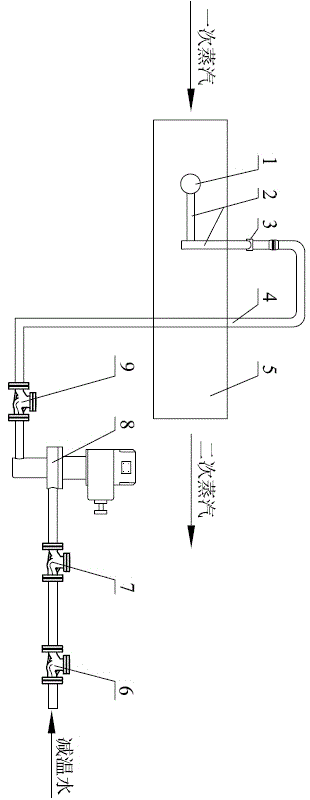

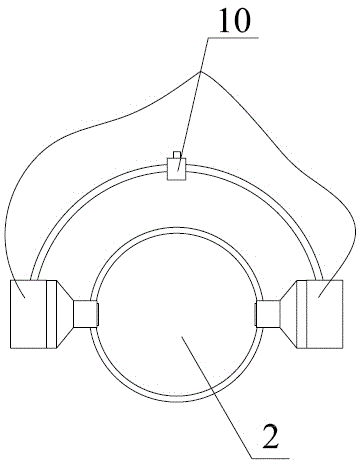

[0011] Example 1. The steam enters the mixing pipe 5 and meets the desuperheating water sprayed from the spherical nozzle 1 located in the middle of the mixing pipe 5. The high temperature carried by the steam is absorbed by the desuperheating water, and its temperature is reduced. The desuperheating water also vaporizes into steam. Due to the spherical design of the nozzle 1 and the uniform distribution of several through holes, the spray range of the desuperheating water is larger, and the distribution of the desuperheating water after spraying is more uniform, so the contact between the desuperheating water and the steam is more sufficient, and the desuperheating effect is more obvious. Temperature accuracy is also higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com