Self-lubricating felt of gear-rack jacking system

A lifting system, rack and pinion technology, applied in the direction of engine lubrication, lifting frame, lifting device, etc., can solve the problems of low lubrication efficiency, high labor cost of grease, low safety, etc., and achieve high lubrication efficiency and reduce lubrication. The effect of high cost and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

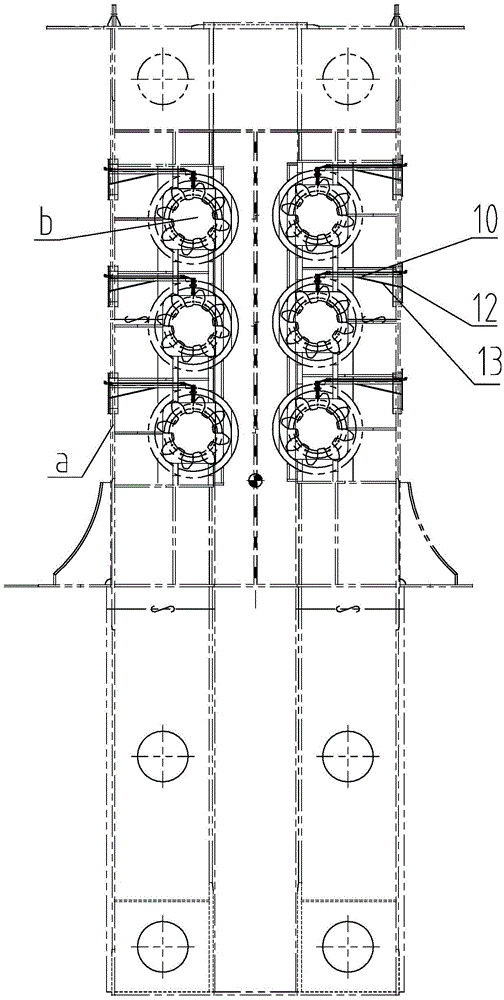

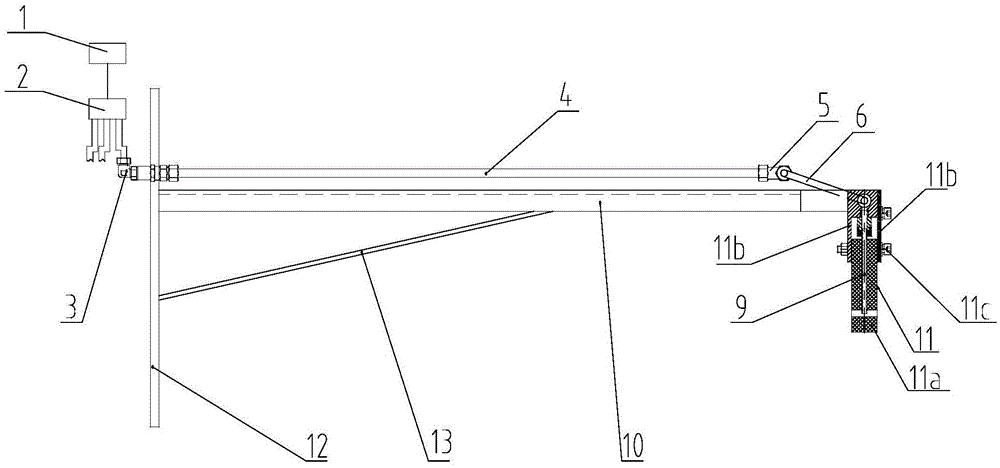

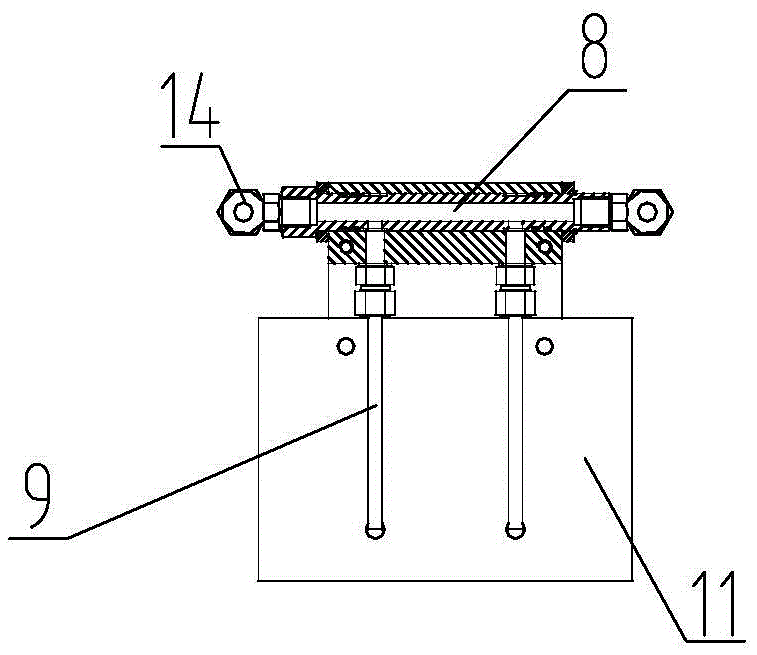

[0027] An embodiment of the present invention provides a self-lubricating felt for a rack and pinion lifting system, such as figure 1 and figure 2 As shown, the self-lubricating felt includes: an electric lubricating pump 1, a distributor 2 and a plurality of self-lubricating components, the oil outlet of the electric lubricating pump 1 communicates with the oil inlet of the distributor 2, and the multiple oil outlets of the distributor 2 The ports are respectively connected with a plurality of self-lubricating components, and the self-lubricating components include: an oil inlet joint 3, a first oil inlet pipe 4, a three-way pipe 5, a second oil inlet pipe 6, a third oil inlet pipe 7, a first oil guide pipe 8, The second oil guide pipe 9, the fixed plate 10 and the felt brush 11, one end of the oil inlet joint 3 communicates with the oil outlet of the distributor 2, and the other end of the oil inlet joint 3 is connected with the first end of the first oil inlet pipe 4 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com