A new dual-purpose valve

A valve, dual-purpose technology, applied in the direction of lift valve, valve device, filtration and separation, etc., can solve the problems of affecting the normal operation of the valve, no filtering function, damage to the precision of the instrument, etc., to prolong the effective water filtration time, the overall structure Simple and practical, less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

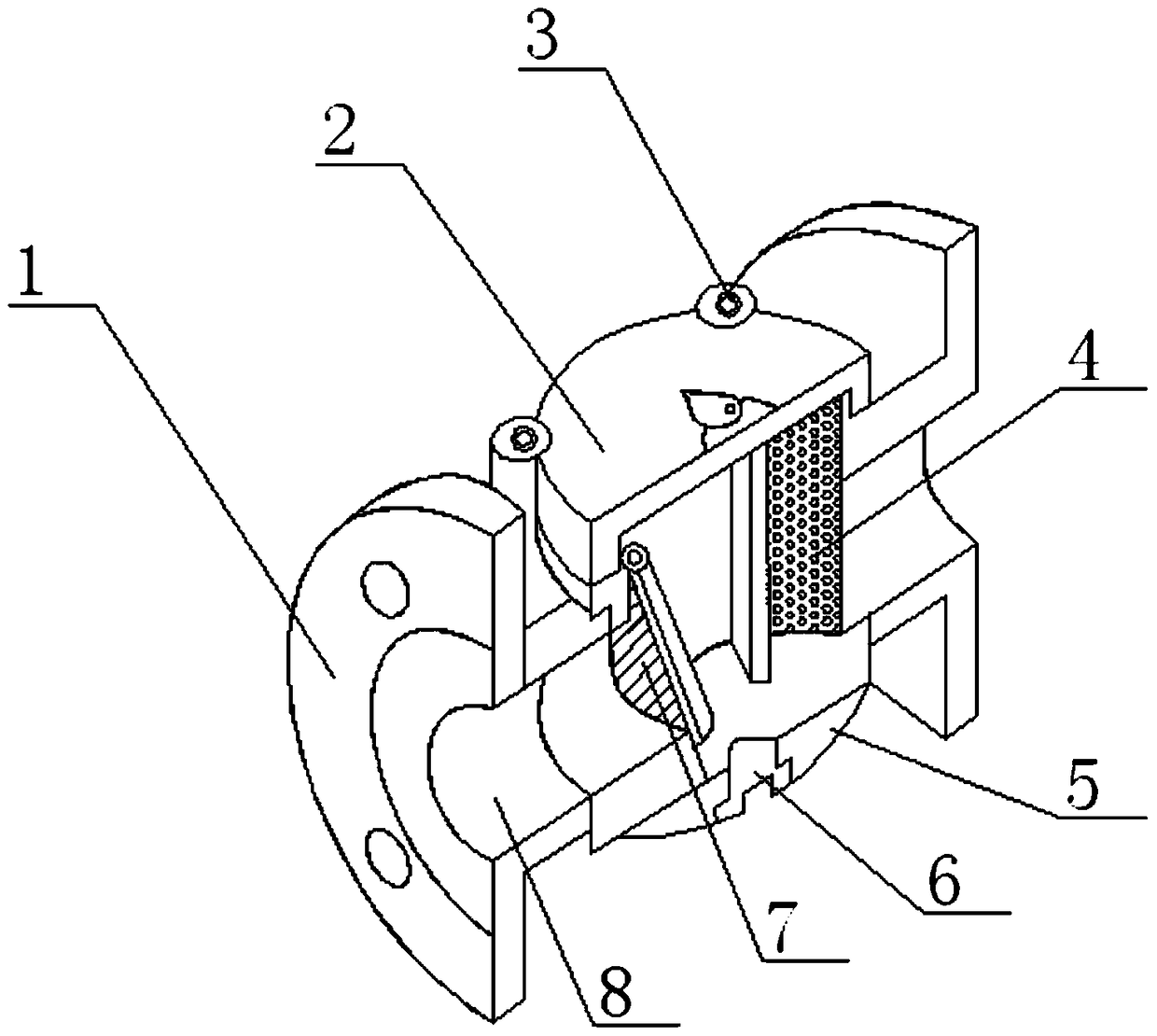

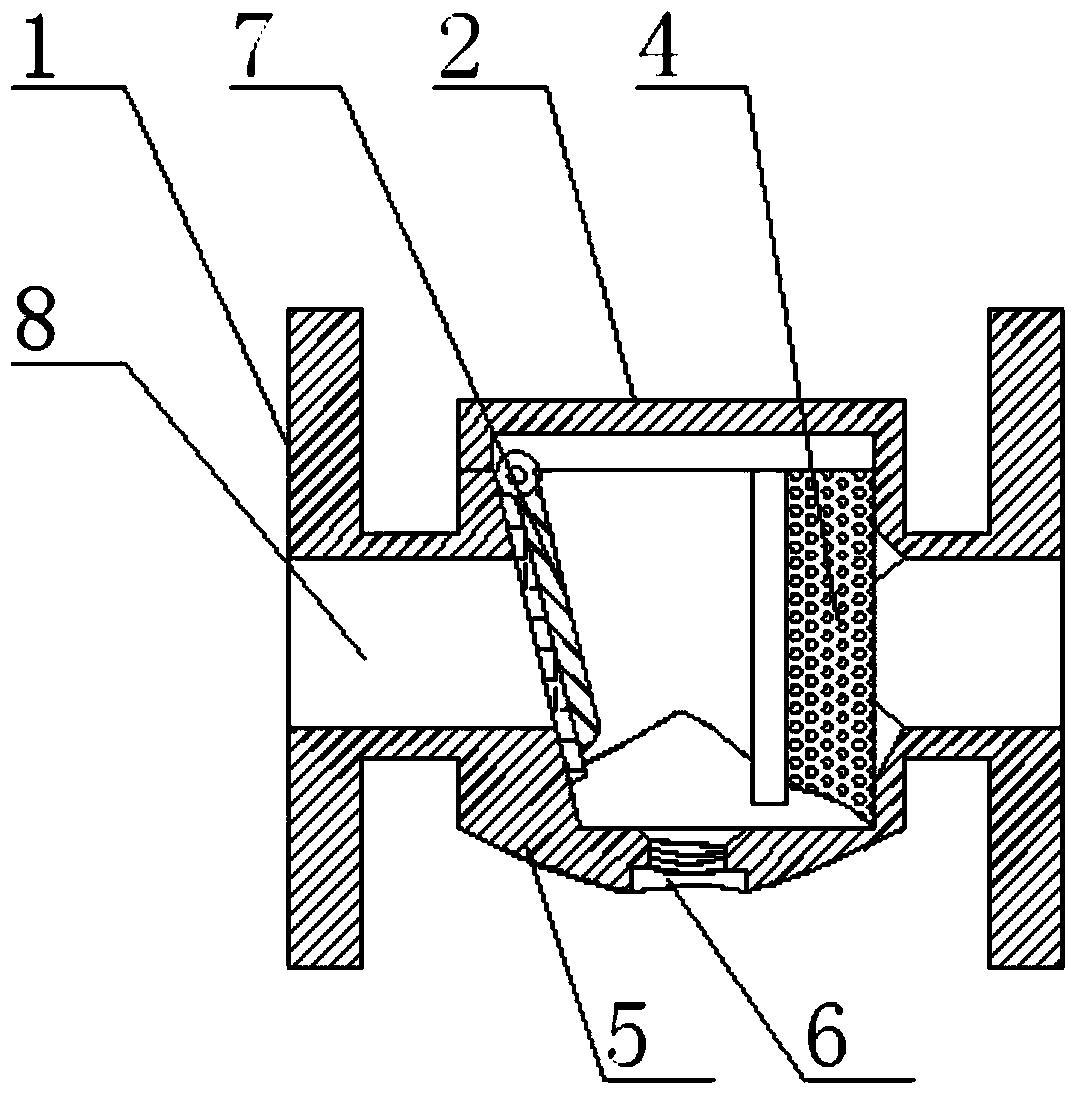

[0030] Such as figure 1 and figure 2 As shown, a new dual-purpose valve includes a valve body, a valve cover, a filter screen and a valve plate. Symmetrical flanges are arranged at both ends of the valve body, and the symmetrical flanges are connected through cylindrical pipes. The upper end of the middle part of the valve body is provided with For the valve cover, there are four symmetrical bolt holes around the upper end of the valve body opposite to the valve cover. A valve plate and a filter screen are provided, and the top of the valve plate is movably connected to the valve wall in the middle of the valve body. The movable connection of the valve plate adopts a pin connection or a hinge connection. The liquid inlet port and the liquid outlet port of the pipeline, the valve plate is an integral structure bonded by a gate plate and a rubber sealing plate, the rubber sealing plate is set facing the liquid inlet port, the filter net, etc. There are filter holes at interva...

Embodiment 2

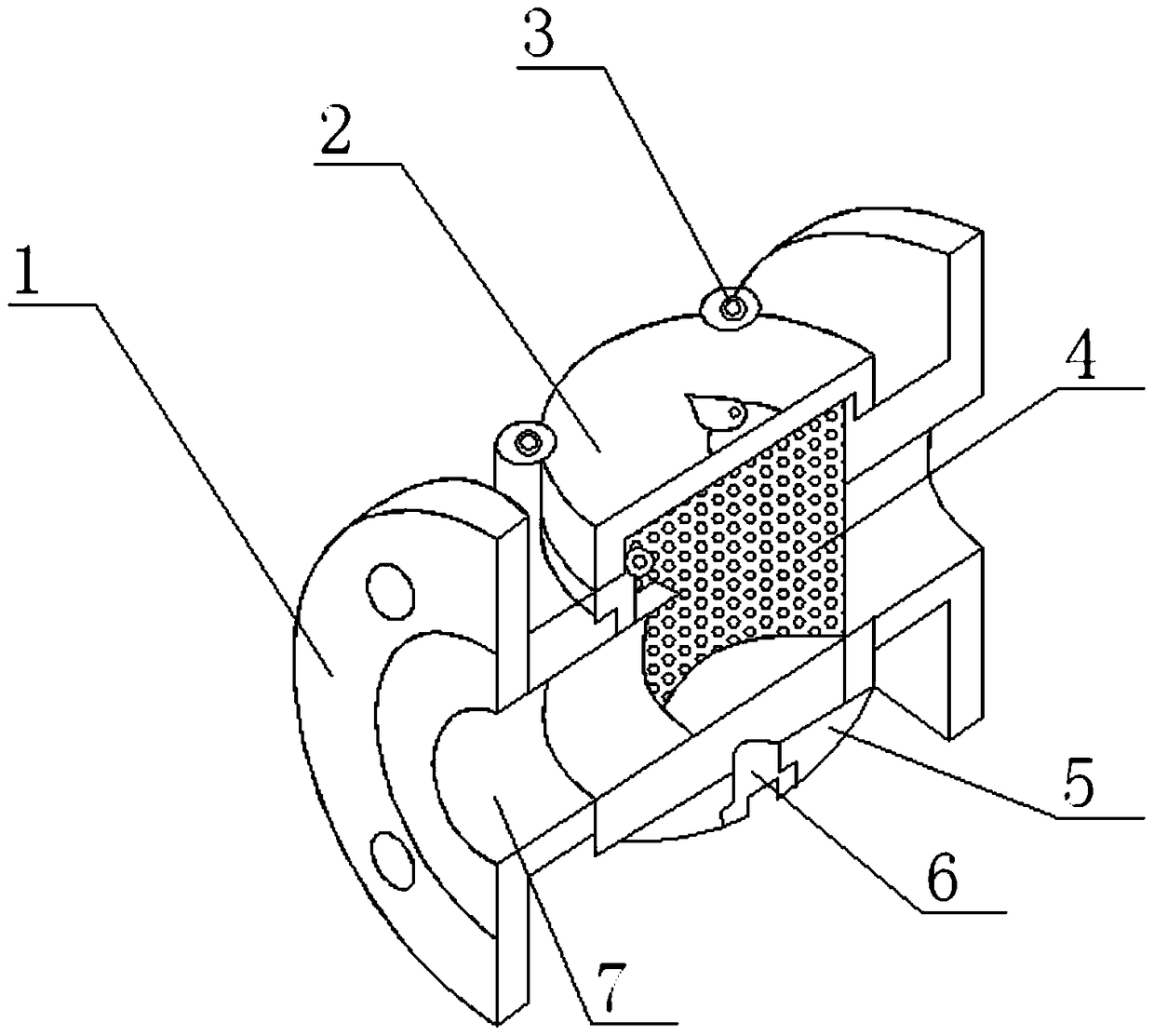

[0033] Such as image 3 and Figure 4 As shown, a new dual-purpose valve includes a valve body, a valve cover and a filter screen. Symmetrical flanges are arranged at both ends of the valve body, and the symmetrical flanges are connected through cylindrical pipes. Four symmetrical bolt holes are arranged around the upper end of the valve body opposite to the bonnet. The bolts are tightly engaged in the bolt holes through the gaskets to tightly connect the bonnet and the valve body. The bonnet is connected to the valve body through bolts. The inside of the valve body at the lower end of the cover is provided with a filter screen, and the filter screen is set as a hollow cylinder structure (such as Figure 5 As shown), the filter screen is provided with filter holes at equal intervals, and the upper and lower ends of the filter screen are respectively connected with the upper and lower valve walls of the valve body to separate the valve body into two cavities. The liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com