Helical tooth planet gear speed reduction mechanism

A technology of reduction mechanism and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve the wear of planetary gear anti-friction pads, sun gear anti-friction pads, and planetary gear reduction mechanism toothing , High heating failure rate, change of gear meshing clearance and other problems, to achieve the effect of reducing heating failure rate, increasing torque and increasing gear overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

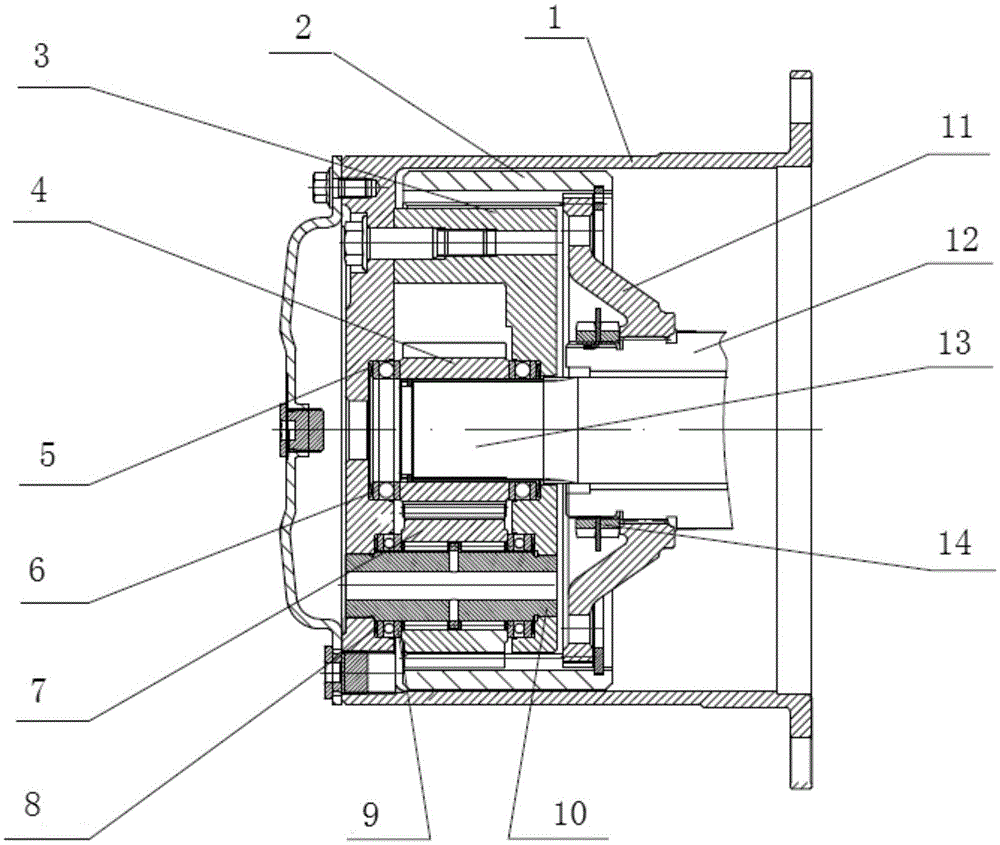

[0023] A helical planetary gear reduction mechanism (see figure 1 shown), including the wheel reducer housing 1, the ring gear 2 installed in the wheel reducer housing 1, the planetary gear bracket 3, the planetary gear 7, the planetary gear shaft 10, the sun gear 4, the planetary gear 7 1. The sun gear 4 is a helical gear; the sun gear 4 is installed on the half shaft 13, the sun gear 4 meshes with the planetary gear 7, the planetary gear 7 is set on the planetary gear shaft 10, and one end of the planetary gear shaft 10 is pressed into the wheel to reduce the speed. In the planetary gear shaft hole of the device housing 1, in the planetary gear shaft hole of the planetary gear bracket 3 at the other end of the planetary gear shaft 10; the planetary gear 7 is also meshed with the ring gear 2, and the ring gear 2 and the ring gear bracket 11 pass through a circlip Connection, the ring gear bracket 11 is connected to the shaft tube 12, and is locked and fixed by the locking nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com