A kind of wind turbine rotor blade structure and preparation method thereof

A technology for rotor blades and wind turbines, which is applied to wind engines, wind engines, and mechanical equipment in the same direction as the wind, and can solve problems such as low stiffness of T-bolt connections, unfavorable structural reliability, and impact on assembly methods, etc., to achieve Conducive to connection strength and reliability, reduced transportation and manufacturing costs, low load factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

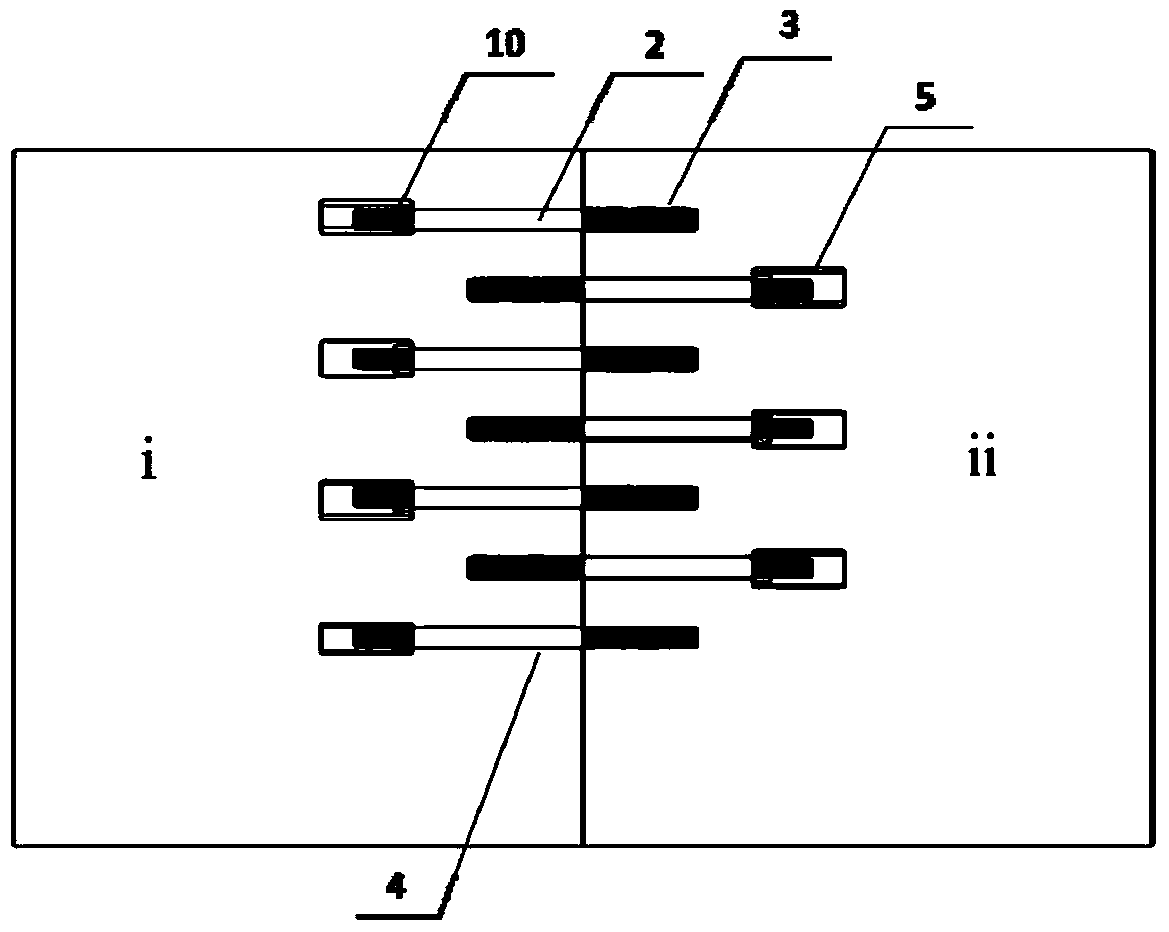

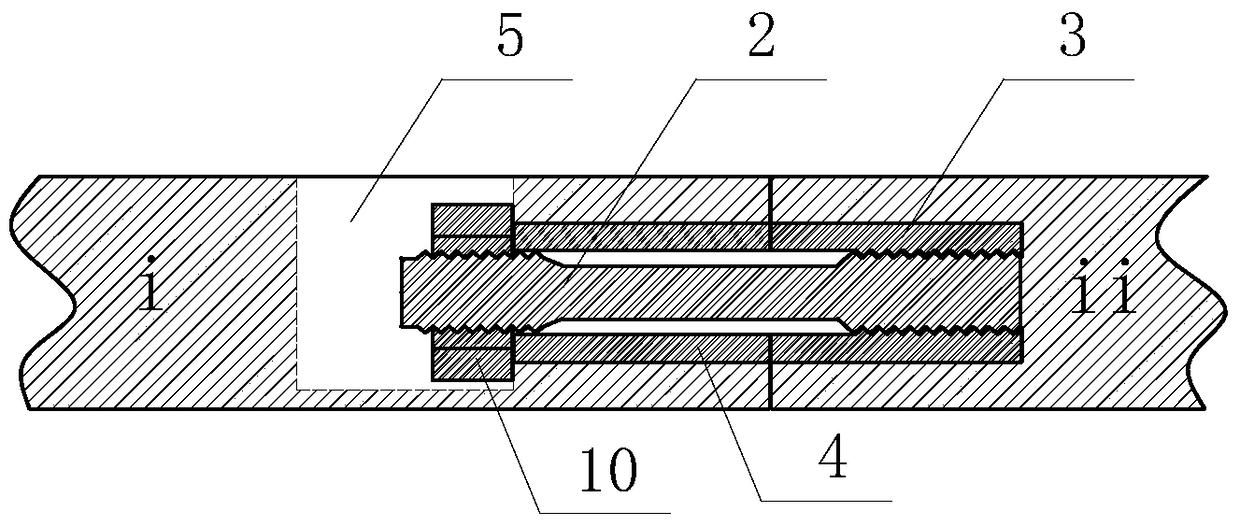

[0035] Such as figure 1 As shown, the rotor blade structure of the wind turbine of the present invention includes at least the first and second blade segments i and ii, and the first and second blade segments i and ii are sequentially connected by connecting bolt groups to form a whole blade , the first and second blade segments i and ii are made of composite material laminations, and can also be partially made of metal materials, and consist of a skin body, studs 2, bolt sleeves 3, light sleeves 4, and a prosthetic cavity 5 composition.

[0036] Such as Figure 1-3 As shown, the bolt sleeves 3 and light sleeves 4 are arranged alternately on the connecting end face of the main body of the skin. The optical sleeve 4 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com