Composite geomembrane anti-seepage structure and construction method that can automatically adapt to weir body deformation

A composite geomembrane, self-adapting technology, applied in similar engineering fields, can solve problems such as loss of due function and difficulty in expansion of expansion joints, reducing tensile or shear damage, reducing strain concentration, and reducing the degree of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

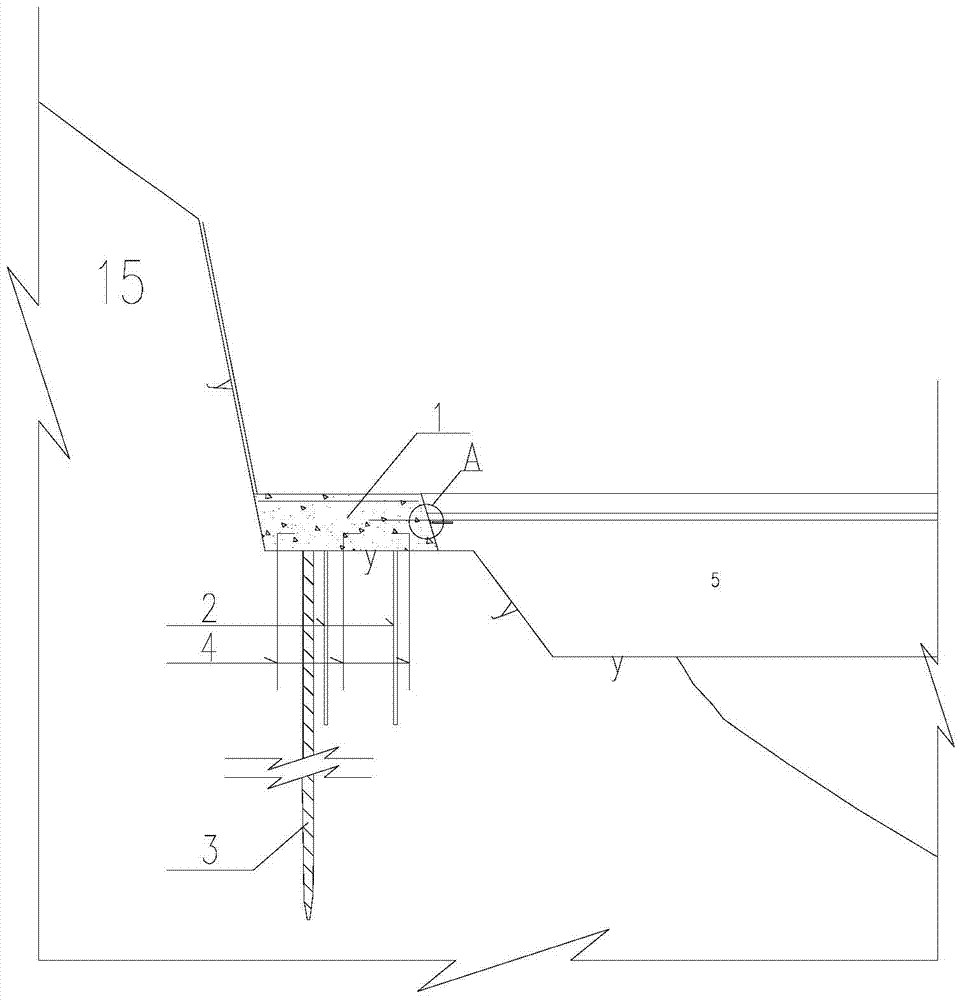

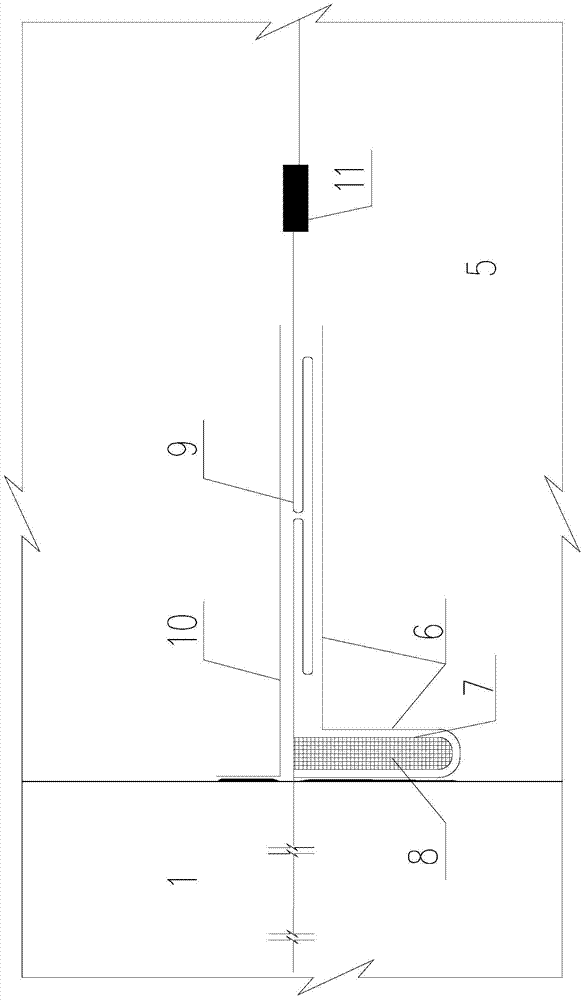

[0033] Embodiment one: if figure 1 , figure 2 As shown, the concrete structure in this example is a concrete plinth 1, one side of the plinth is the shore bedrock 15, and the other side is connected with the cushion layer 5, and the bottom plate of the concrete plinth 1 and the shore bedrock are connected by anchor bars 4 is connected with the consolidation grout 2 and the grouting curtain 3 is set along the axis of the concrete plinth 1; The inner end of the upper protective layer PE film 10 and the subsequent part of the lower protective layer PE film 6 are respectively covered on the U-shaped expansion joint 7 and the auxiliary horizontal expansion joint by painting asphalt with a thickness of 0.2mm and the surface of the concrete toe slab 1. 9 upper and lower surfaces.

[0034] The construction method of embodiment one is as follows:

[0035] a. Concrete plinth 1 and anti-seepage system setting: one side of the concrete plinth 1 is the shore bedrock 15, which provides ...

Embodiment 2

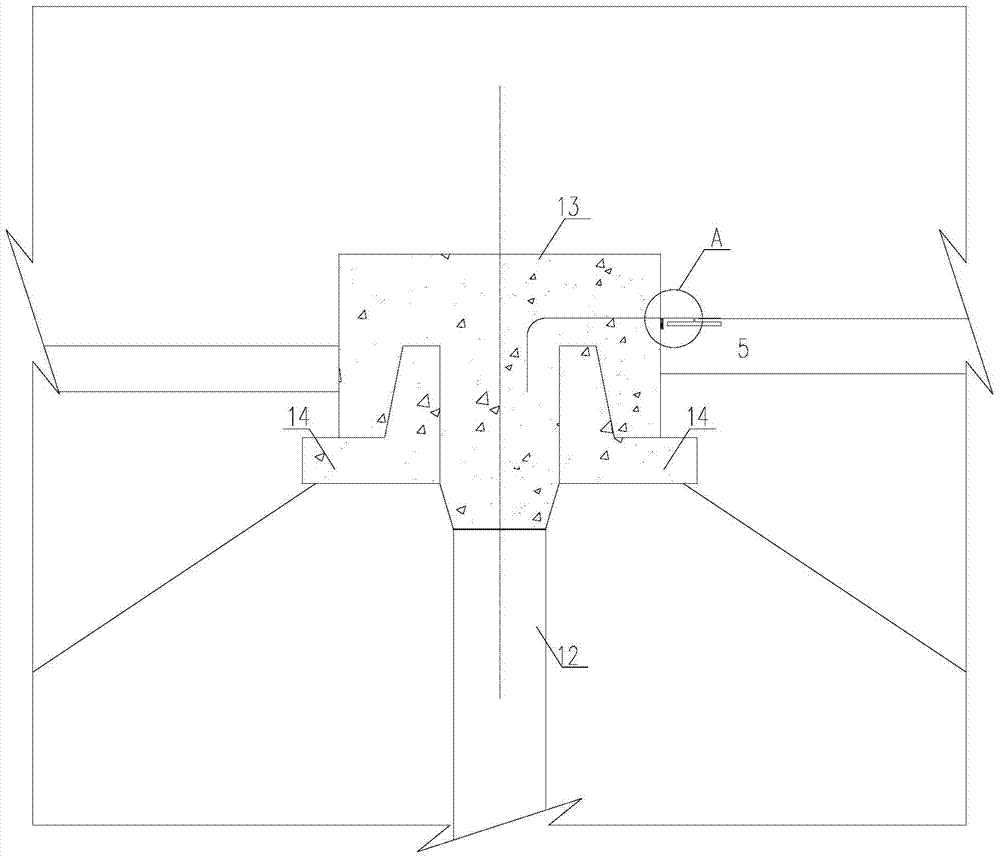

[0042] Embodiment two: if figure 2 , image 3 As shown, the concrete structure of this example is an anti-seepage wall 12, and the top of the anti-seepage wall is a concrete cap 13 and a guide wall 14; The inner end of the lower protective layer PE film 6 is bonded to the surface of the concrete cap 13 by painting asphalt with a thickness of 0.2mm, and the subsequent parts of the upper protective layer PE film 10 and the lower protective layer PE film 6 are respectively covered on the U-shaped expansion joint 7 and The upper surface and the lower surface of the auxiliary horizontal expansion joint 9.

[0043] The construction method of embodiment two is as follows:

[0044] a. Concrete anti-seepage wall 12 and anti-seepage system setting: the upper end of the concrete anti-seepage wall 12 is a concrete cap 13 and a guide wall 14, and the two sides of the concrete cap 13 are connected to the cushion layer 5;

[0045] b. Setting of cushion layer 5: below the cushion layer 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com