High-durability two-stage snake-shaped interconnected wire structure

An interconnection wire, durability technology, applied in the field of high-durability secondary serpentine interconnection wire structure, can solve problems such as reducing wire durability, and achieve the effects of reducing strain concentration, reducing tensile burden, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

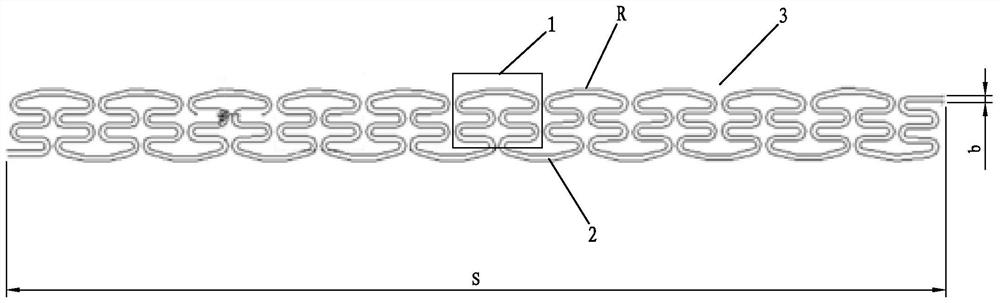

[0017] refer to figure 1 , this embodiment relates to a highly durable two-level serpentine interconnection wire structure, including a plurality of first-level serpentine wire structures 1 connected in sequence, and two adjacent first-level serpentine wire structures 1 are connected together by arc-shaped wires 2 , forming a second-level serpentine interconnection wire structure 3 .

[0018] In this structure, an arc-shaped wire 2 having the same width as the wire of the first-level serpentine wire structure 1 is used to connect two adjacent first-level serpentine wire structures 1 . When the wire is stretched, the curved wire 2 will provide the amount of lateral stretch required for stretching, thereby reducing the stretching burden on the wire material, thereby reducing the strain concentration inside the wire material, thereby improving the durability of the wire , that is, compared with the original connection structure of straight wires, this structure can provide a gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com