The preparation process of one-time molding pc box

A preparation process and box body technology, which is applied in the field of one-time molding PC box preparation, can solve the problems of difficult PC materials, no disclosure of PC bags and other problems, and achieve the effects of good hardness, low density, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

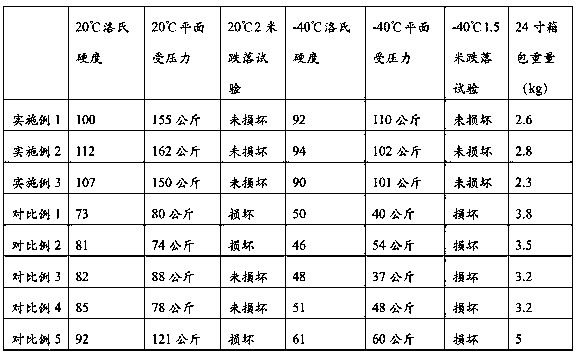

Examples

Embodiment 1

[0029] Step 1: After drying the PC material, it is worth drying the PC material;

[0030] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0031] Step 3: Calculate 1000 parts by weight of the PC material in step 1, 10 parts of styrene-acrylamide copolymer, 0.7 parts of zirconium phosphate, 1 part of hydrotalcite, 1 part of zinc borate, 3 parts of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0032] Step 4: Add the PC raw material obtained in Step 3 into the mold with a high-speed injection molding machine and inject it directly into a box. The speed of the high-speed injection molding machine is 150r / min, the temperature is 100°C, and the injection molding time is 5-15 seconds;

[0033] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0034] Step 6: Dehumidify the box body obtained in Step 5 and pa...

Embodiment 2

[0036] Step 1: After drying the PC material, it is worth drying the PC material;

[0037] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0038] Step 3: Calculate 1500 parts by weight of the PC material in step 1, 3 parts of styrene-acrylamide copolymer, 0.5 parts of zirconium phosphate, 2 parts of hydrotalcite, 0.5 parts of zinc borate, 1 part of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0039] Step 4: The PC raw material obtained in Step 3 is injected into the mold by a high-speed injection molding machine and directly injected into a box body. The speed of the high-speed injection molding machine is 200r / min, the temperature is 160°C, and the injection molding time is 10 seconds;

[0040] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0041] Step 6: Dehumidify the box body obtained in Ste...

Embodiment 3

[0043] Step 1: After drying the PC material, it is worth drying the PC material;

[0044] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0045] Step 3: Calculate 2000 parts by weight of PC material in step 1, 7 parts of styrene-acrylamide copolymer, 1.5 parts of zirconium phosphate, 3 parts of hydrotalcite, 1.5 parts of zinc borate, 2 parts of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0046] Step 4: The PC raw material obtained in Step 3 is injected into the mold by a high-speed injection molding machine and directly injected into a box body. The speed of the high-speed injection molding machine is 170r / min, the temperature is 200°C, and the injection molding time is 15 seconds;

[0047] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0048] Step 6: Dehumidify the box body obtained in Step 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com