Static pressure molding process device for porcelain packing

A technology of static pressure molding and process equipment, which is applied in the field of product compression molding, can solve the problems of not meeting the user's design and use requirements, difficult to achieve product size and geometry, short service life, etc., to achieve excellent quality, reliability, easy operation and maintenance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

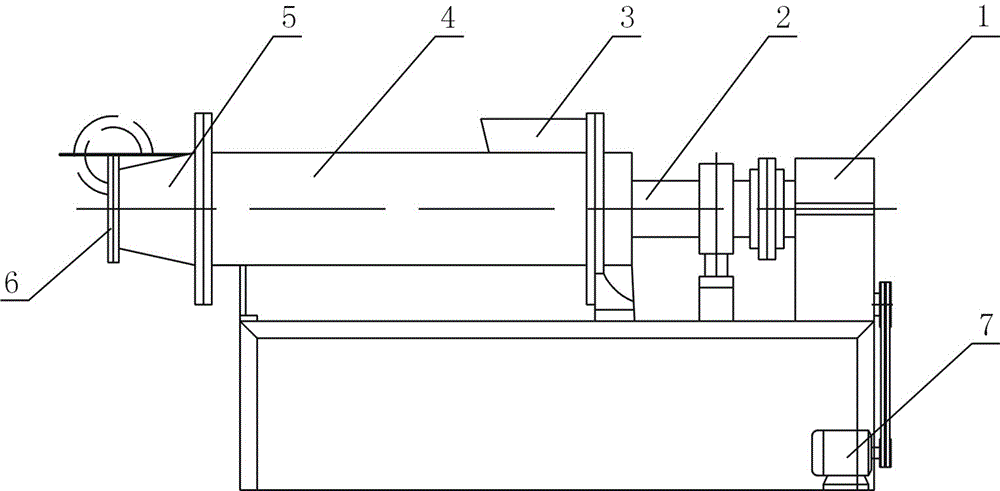

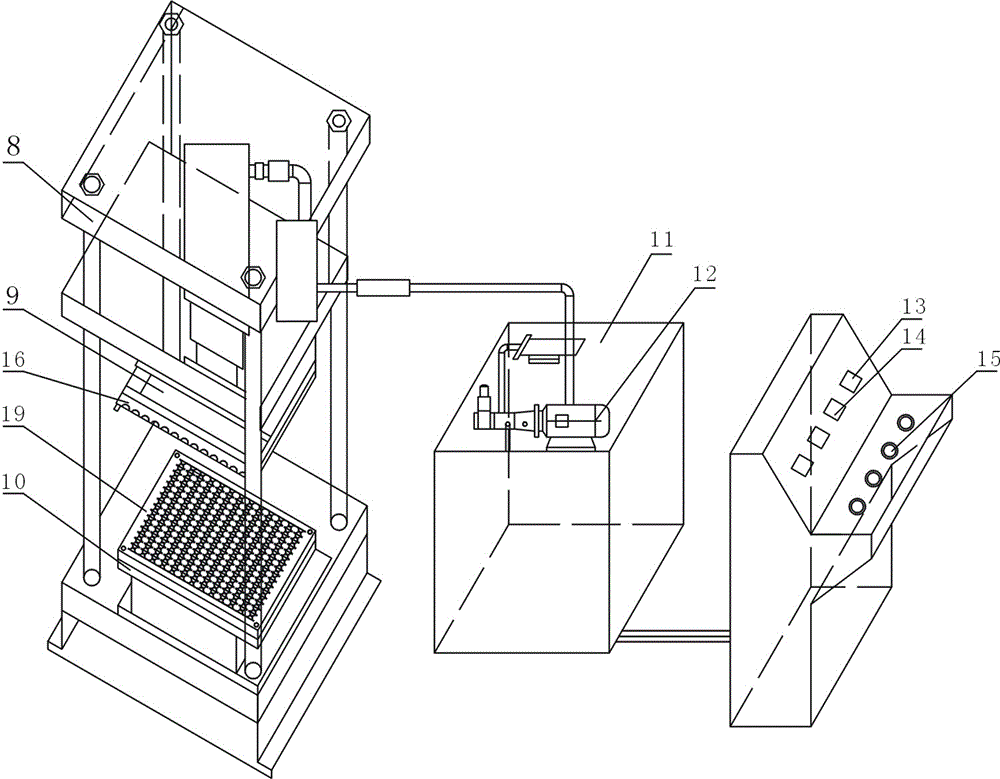

[0027] The purpose of the present invention is achieved by the following examples, specifically taking the pressed moment saddle ring porcelain filler as an example:

[0028] The first step is to purchase commercial hydraulic presses 8 and electric control components, power components and related auxiliary components;

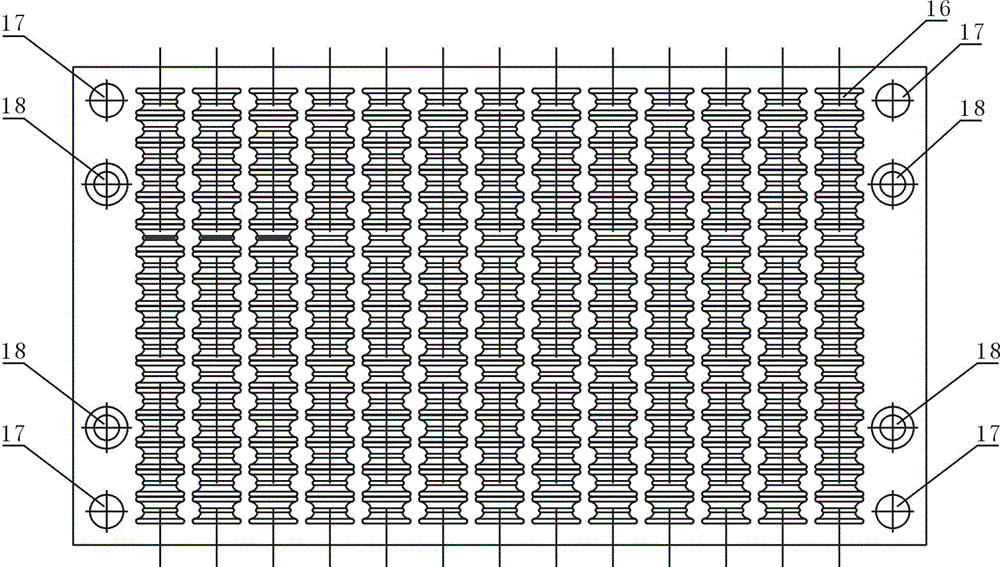

[0029] In the second step, process the upper concave forming steel mold 16 and the lower convex forming steel mold 19 designed by the present invention, and set the guide mold column hole 17 and the bolt hole 18 on the upper concave forming steel mold 16; Set up mud discharge hole 20, guide mold column hole 17, bolt hole 18;

[0030] The third step is to install the upper concave forming steel mold 16 on the upper cylinder piston column 9 on the hydraulic press 8, and fix the upper concave forming steel mold 16 to the upper cylinder of the hydraulic press 8 through bolt holes 18 with four M16 inner hexagonal bolts. On the upper working surface of the piston co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com