High-precision automatic assembling and detecting equipment for electric toothbrush handle shell

An electric toothbrush and automatic assembly technology, applied in metal processing equipment, liquid tightness measurement using liquid/vacuum degree, metal processing, etc., can solve the problem that manual assembly cannot record production data, and the accuracy of fixtures is difficult to meet the requirements and cannot be realized Retrospective and other issues, to achieve the effect of compact structure, uniform and stable pressure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

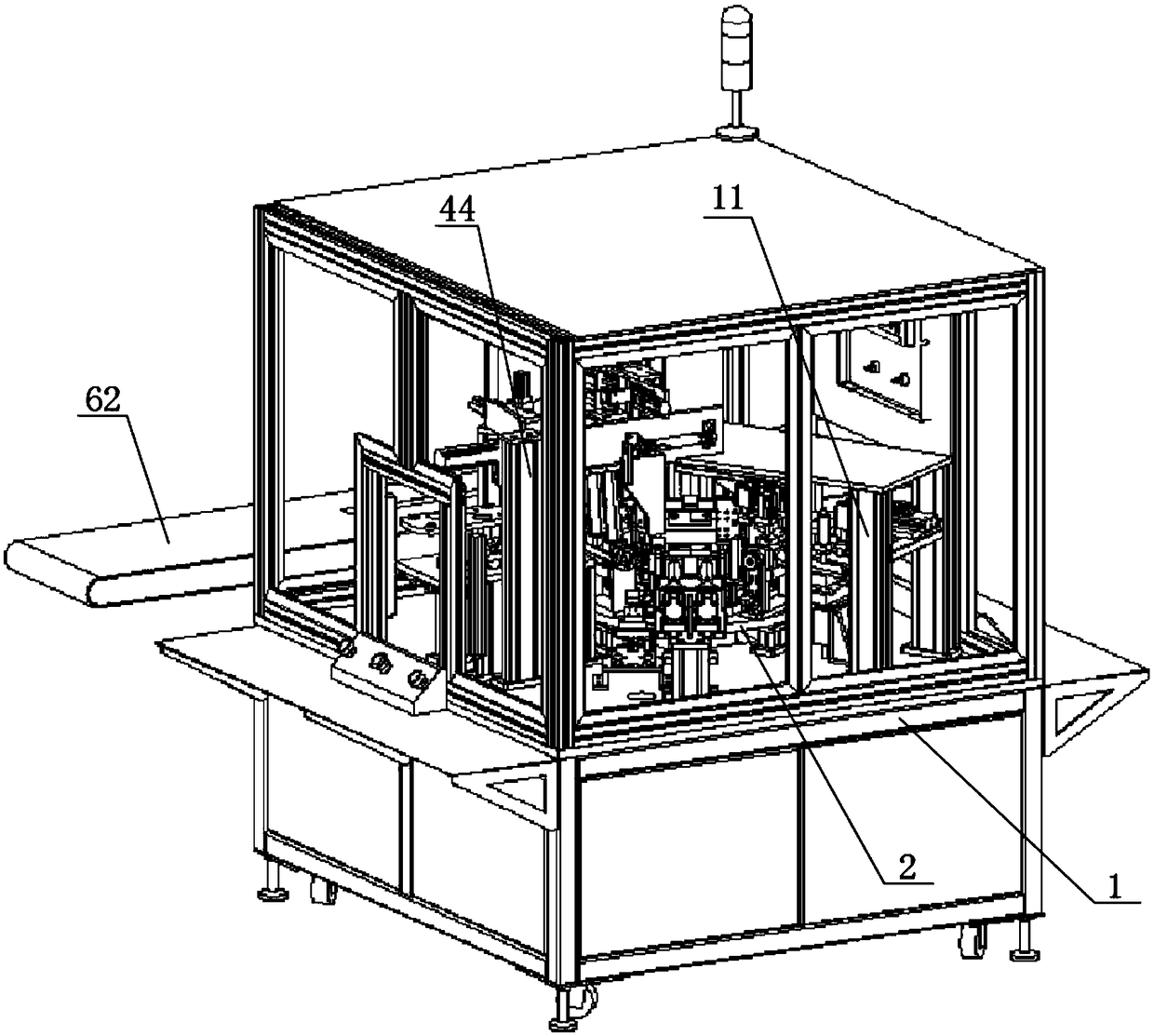

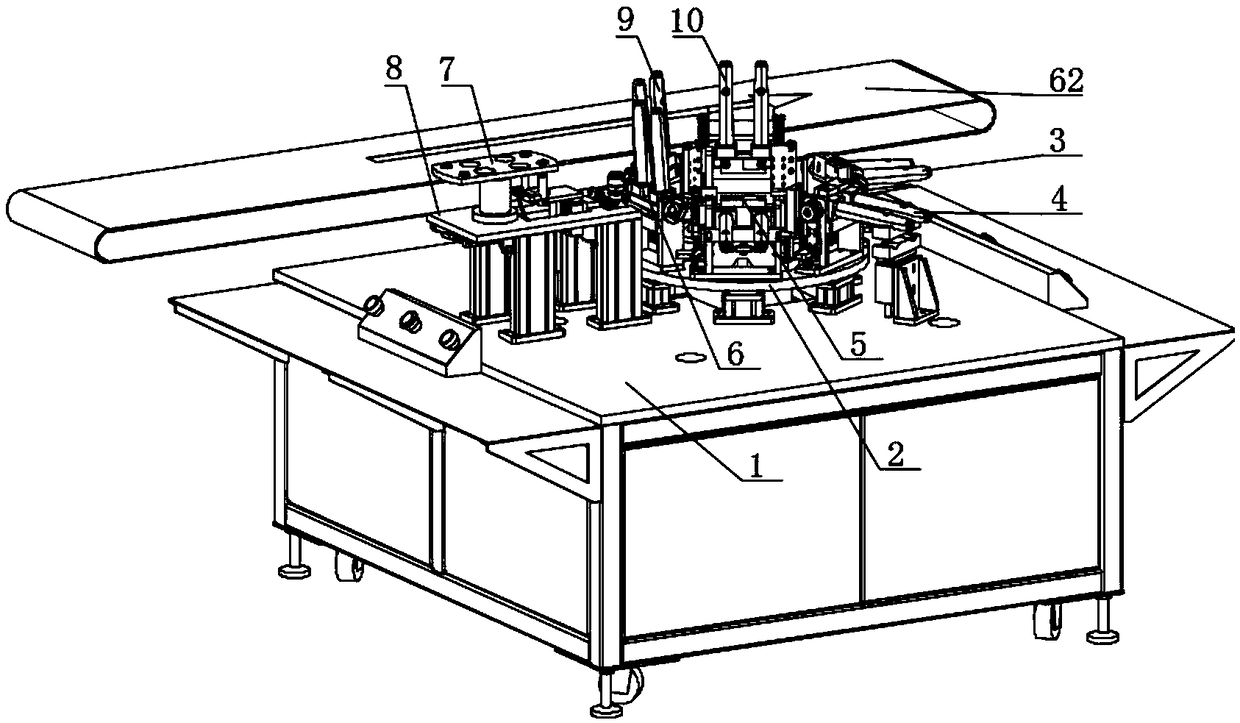

[0038] Such as figure 1 , figure 2 and image 3As shown, the high-precision electric toothbrush handle shell automatic assembly detection equipment of this embodiment includes a frame 1, a sextant turntable 2 is installed on the upper surface of the frame 1, and a sextant turntable 2 is installed on the side of the sextant turntable 2. There is a two-position table 8, a sealing ring feeding mechanism 7 is installed on the two-point table 8, and a six-point turntable 2 is in a circular structure, and six jigs with the same structure are evenly installed along the circumference of the circular structure. A jig rotates with the sextant turntable 2, and respectively forms six operating stations with the actuator installed on the outer ring frame 1 of the sextant turntable 2. The six operating stations are: the main body of the handle and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com