Charging hydraulic tool

A hydraulic tool, rechargeable technology, applied in the direction of manufacturing tools, portable mobile devices, etc., can solve the problems of increasing safety hazards, inconsistent crimping direction of insulated wire copper joints, safety hazards, etc., to achieve easy on-site portability, reduce tool investment, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

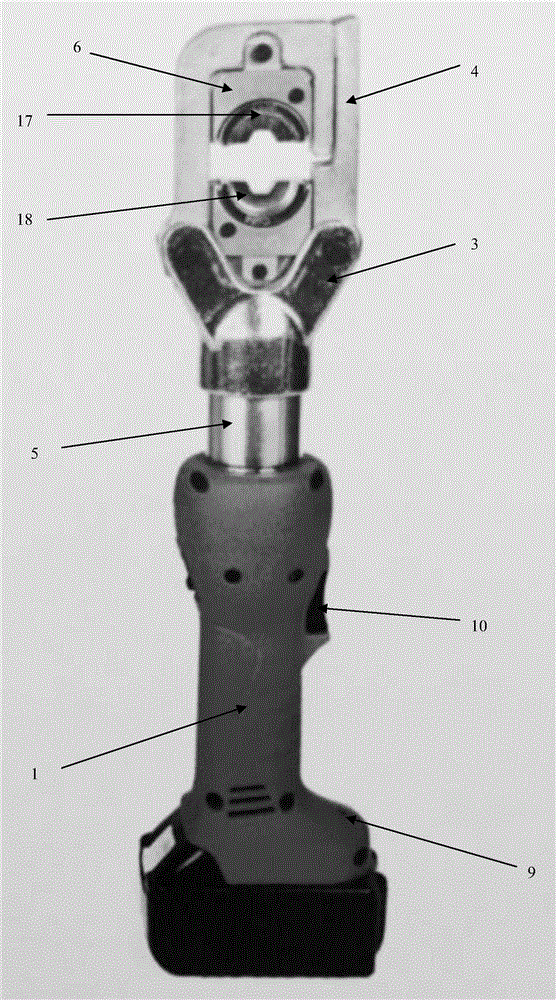

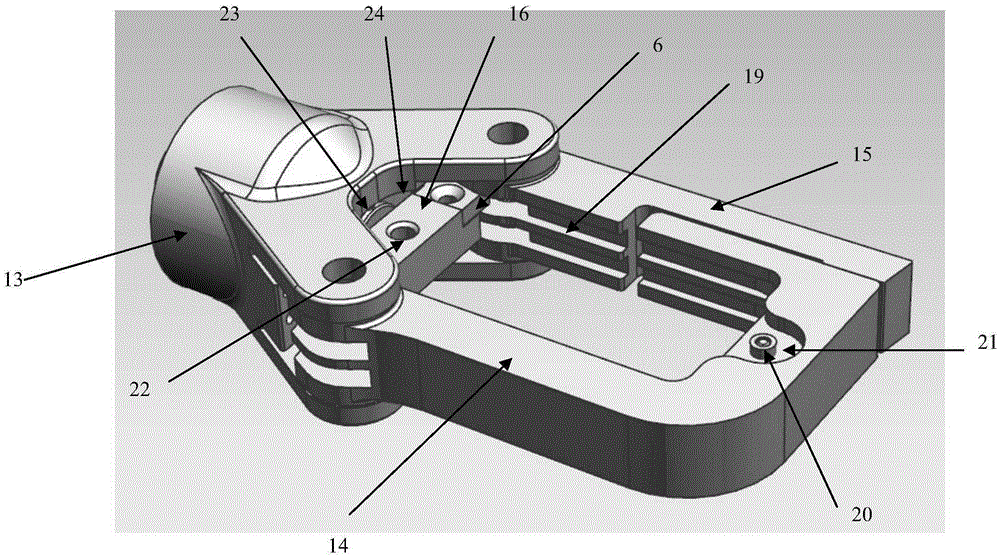

[0021] Refer to attached picture.

[0022] The rechargeable hydraulic tool of the present invention includes a handle 1, a hydraulic drive part 2 and an end structure 3, the end structure 3 includes a working head 4, and a replaceable working part 6 is arranged on the working head 4, and the replaceable working part 6 For matching jaws, cutters or crimping dies. The rechargeable hydraulic tool also includes a connection mechanism 5 between the hydraulic drive part 2 and the end structure 3. The connection mechanism 5 is a rotatable part, and the rotatable connection mechanism 5 can transmit the jacking force of the hydraulic drive part 2. The end structure 3 rotates 360° without dead angle.

[0023] The connecting mechanism 5 is a damping rotating shaft, and one end of the connecting mechanism 5 extends into the handle 1 and is flexibly connected with the handle 1. The flexible connection here refers to an unfixed connection, and the connecting mechanism 5 can reciprocate up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com